Solid-liquid hybrid rocket combined cycle propelling system and control method thereof

A solid-liquid mixing and propulsion system technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of difficult propellant development and ignition, inaccurate gas flow adjustment, complex system structure, etc. The effect of multiple starts, avoiding unstable combustion, and simple system structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

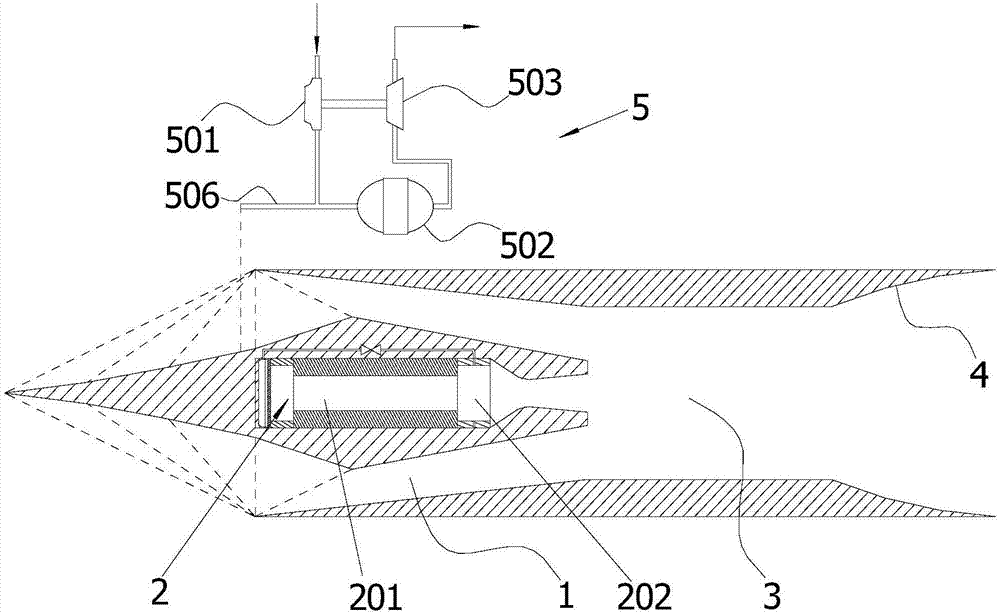

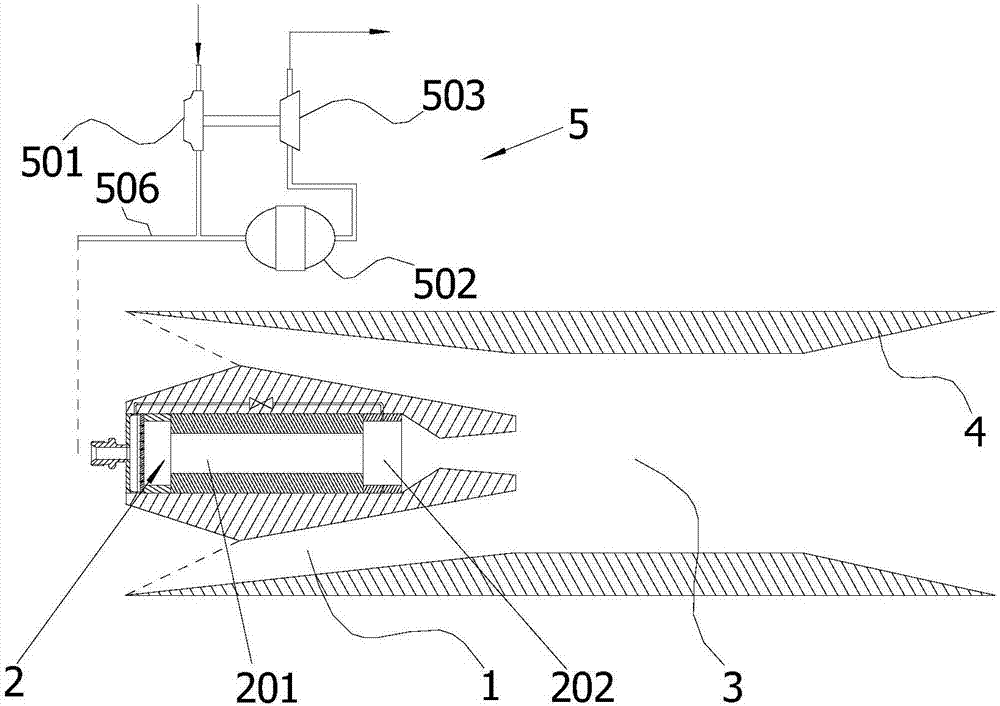

[0041] This embodiment provides a solid-liquid hybrid rocket combined cycle propulsion system, wherein: figure 1 It is a schematic structural diagram of the solid-liquid hybrid rocket combined cycle propulsion system provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the solid-liquid hybrid rocket combined cycle propulsion system includes an air inlet 1 , a solid-liquid hybrid rocket engine 2 , a superchamber 3 , a tail nozzle 4 and an oxidizer delivery device 5 . Specifically, the solid-liquid hybrid rocket engine 2, the superchamber 3 and the tail nozzle 4 are communicated successively. Wherein, a combustion chamber 201 and a supplementary combustion chamber 202 are successively arranged in the solid-liquid hybrid rocket engine 2 . The air inlet 1 is arranged on the circumferential outer side of the solid-liquid hybrid rocket engine 2 and directly communicates with the superchamber 3 . In addition, the oxidant delivery device 5 is respectively c...

specific Embodiment 2

[0045] Such as figure 1 As shown, the solid-liquid hybrid rocket combined cycle propulsion system includes an air inlet 1 , a solid-liquid hybrid rocket engine 2 , a superchamber 3 , a tail nozzle 4 and an oxidizer delivery device 5 . Specifically, the solid-liquid hybrid rocket engine 2, the superchamber 3 and the tail nozzle 4 are communicated successively. Wherein, a combustion chamber 201 and a supplementary combustion chamber 202 are successively arranged in the solid-liquid hybrid rocket engine 2 . The air inlet 1 is arranged on the circumferential outer side of the solid-liquid hybrid rocket engine 2 and directly communicates with the superchamber 3 . In addition, the oxidant delivery device 5 is respectively connected to the combustion chamber 201 and the afterburner chamber 202 .

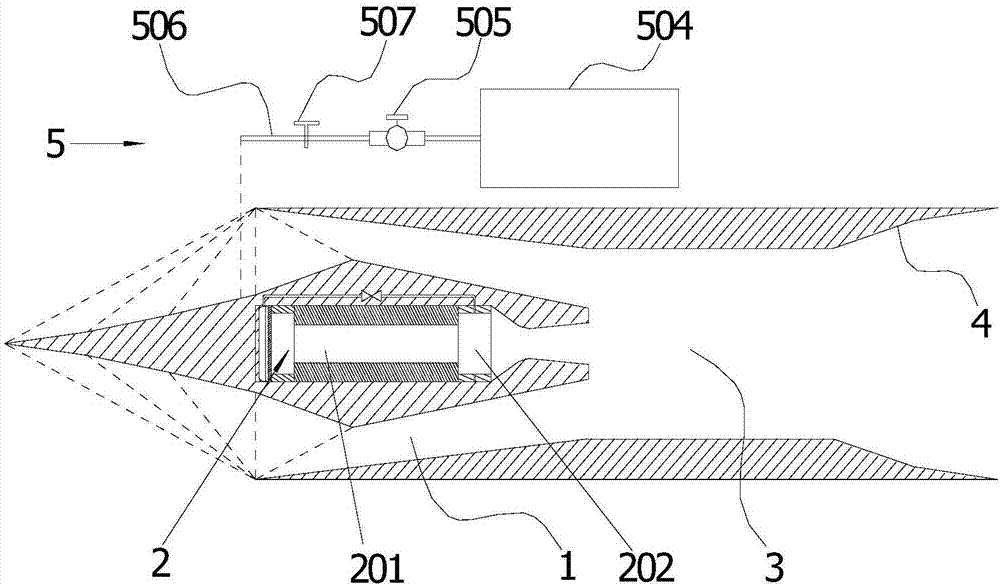

[0046] image 3 It is a schematic structural diagram of the solid-liquid hybrid rocket combined cycle propulsion system provided by Embodiment 2 of the present invention. Optionally, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com