Processing technology for production of glasses lens specially used for safe driving

A technology for safe driving and processing technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of resin lens performance degradation, absorbent instability, etc., to achieve reduced additives, stable and reliable process, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention is a processing technology for producing special lenses for safe driving, and the processing technology includes the following steps:

[0042] (1) Process resin semi-finished products into resin substrates or conduct visual inspection, pretreatment, and clamping of resin substrates;

[0043] (2) Add 0.08% VL462 to the top coating hardening liquid MP7110 of SDC, stir well until it is completely dissolved, then add it into the hardening liquid tank in the hardening machine and circulate it with a 5 μm filter element for 24 hours;

[0044] (3) The lens is hardened by an automatic hardening machine. The pulling speed of the solution prepared in step (2) is set at 1.5mm / s. After the pulling is completed, it is placed in an oven at 115°C for 2.5 hours to cure;

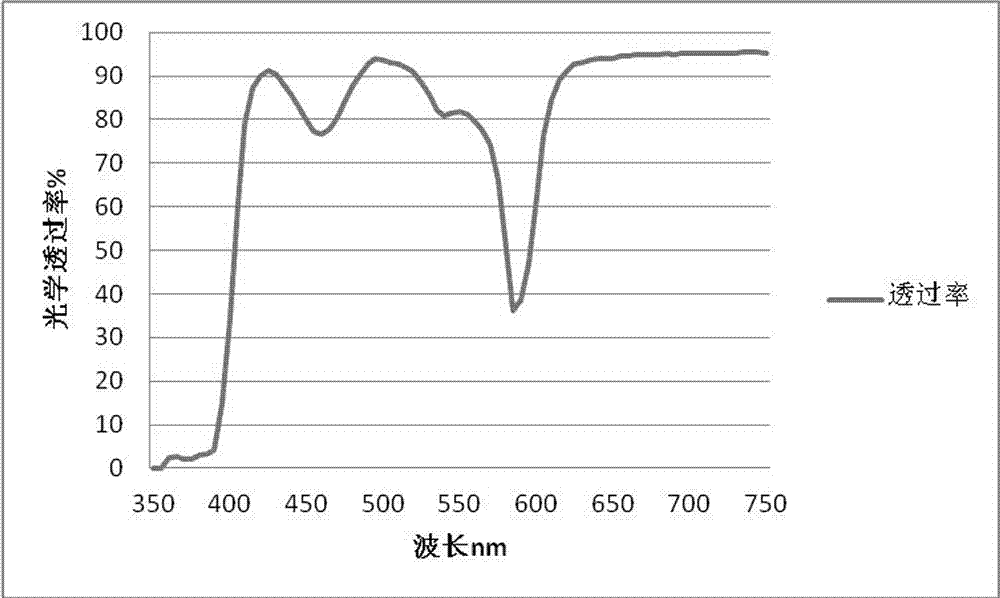

[0045] (4) The lens cured in step (3) is transferred to a vacuum coating machine to be coated with a 585nm narrow-band visible light reflective coating layer.

Embodiment 2

[0047] The present invention is a processing technology for producing special lenses for safe driving, and the processing technology includes the following steps:

[0048] (1) Process resin semi-finished products into resin substrates or conduct visual inspection, pretreatment, and clamping of resin substrates;

[0049] (2) Add 0.14% VL462 to the top coating hardening solution MP7110 of SDC, stir well until it is completely dissolved, then add it to the hardening solution tank in the hardening machine and circulate it with a 5 μm filter element for 24 hours;

[0050] (3) The lens is hardened by an automatic hardening machine. The pulling speed of the solution prepared in step (2) is set at 1.5mm / s. After the pulling is completed, it is placed in an oven at 115°C for 2.5 hours to cure;

[0051] (4) The lens cured in step (3) is transferred to a vacuum coating machine to be coated with a 585nm narrow-band visible light reflective coating layer.

Embodiment 3

[0053] The present invention is a processing technology for producing special lenses for safe driving, and the processing technology includes the following steps:

[0054] (1) Process resin semi-finished products into resin substrates or conduct visual inspection, pretreatment, and clamping of resin substrates;

[0055] (2) Add 0.2% VL462 to the top coating hardening solution MP7110 of SDC, stir well until it is completely dissolved, then add it into the hardening solution tank in the hardening machine and circulate it with a 5 μm filter element for 24 hours;

[0056] (3) The lens is hardened by an automatic hardening machine. The pulling speed of the solution prepared in step (2) is set at 1.5mm / s. After the pulling is completed, it is placed in an oven at 115°C for 2.5 hours to cure;

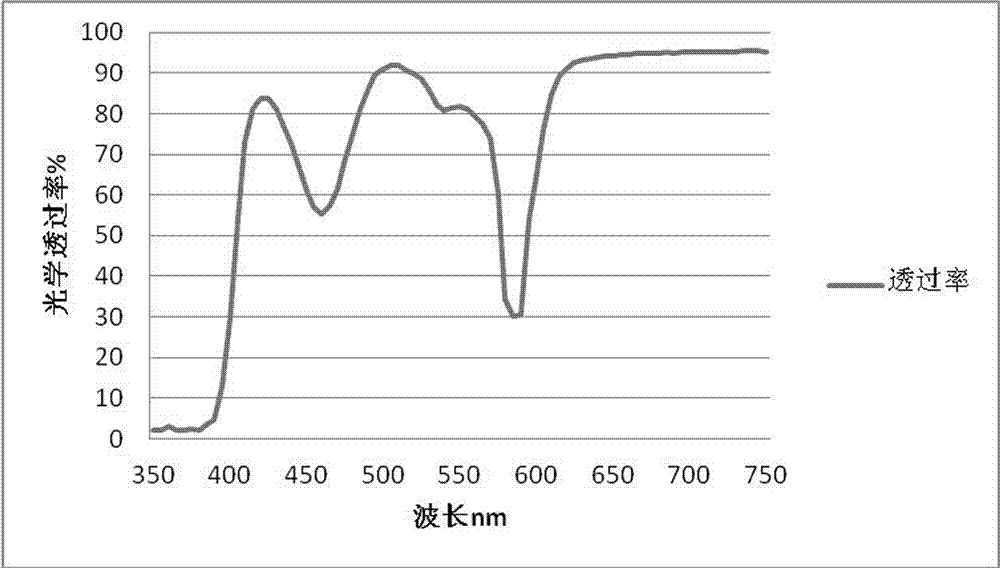

[0057] (4) Apply a layer of UV adhesive evenly on the front surface of the lens after hard coating in step (3) with a spin coater, then adhere the polarizing film to the surface of the lens, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com