Additive and subtractive manufacturing device and method for large complicated metal structural member

A technology for metal structural parts and manufacturing devices, which is applied to the field of manufacturing devices for adding and subtracting materials for large and complex metal structural parts, and achieves the effects of high-efficiency deposition, flexible process, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

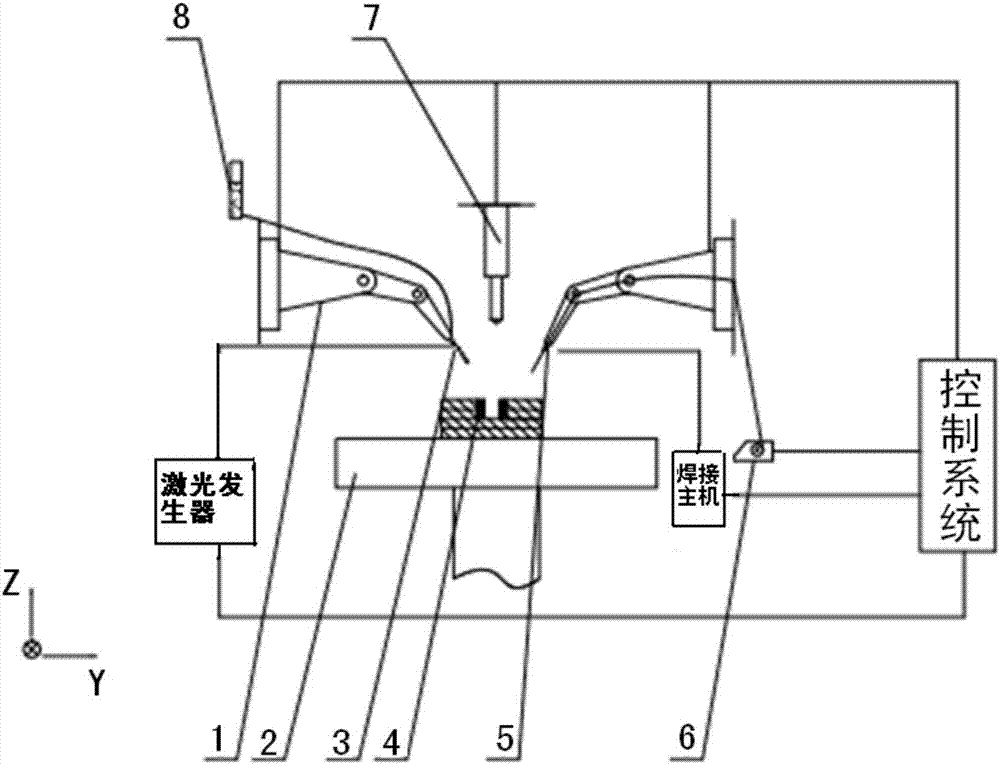

[0038] see figure 1 , the present invention's large-scale and complex metal structural parts addition and subtraction manufacturing device: including a working platform 2, a number of robots 1, a laser head 3, a molded part 4, a welding torch 5, a wire feeding system 6, a milling system 7, a powder feeding system 8, a laser Generator 9, arc welding host 10 and control system 11. The robot 1 is the moving carrier of the laser head 3 , the welding torch of the arc welding host 10 , the wire feeding system 6 , and the powder feeding system 8 . The robot 1 and the milling system 7 are arranged above the working platform 2, the molded part 4 is formed on the working platform 2, the wire feeding system 6 is the wire feeding material for the robot 1; the powder feeding system 8 is feeding the powder material for the robot 1; Laser generator 9 provides laser heat source for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com