Ion exchange resin wastewater zero-emission treatment method

The technology of an ion exchange resin and a treatment method is applied in the field of zero discharge treatment of ion exchange resin wastewater, which can solve the problems of high cost, high treatment difficulty and high salt content in wastewater, and achieve the effects of cost realization, pollution avoidance and zero discharge realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

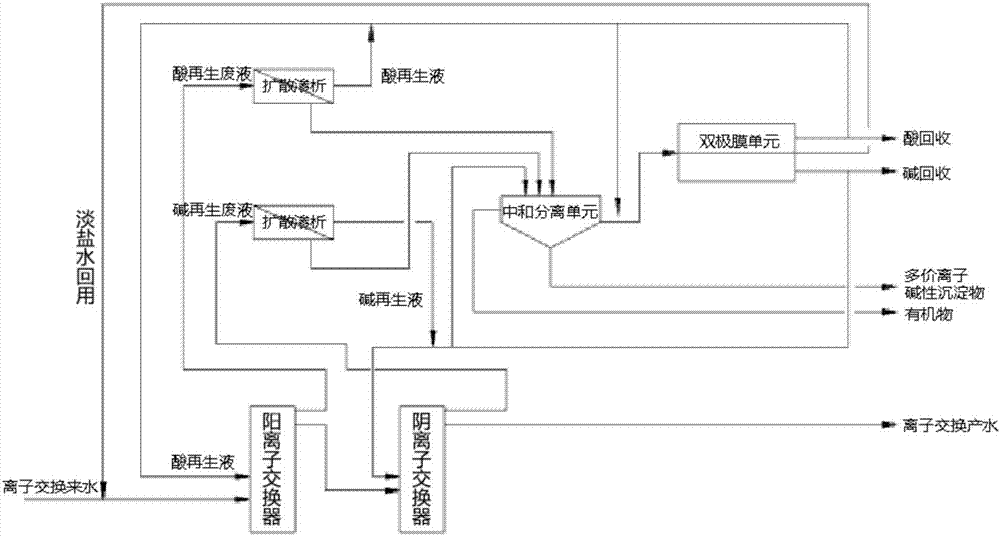

[0022] Such as figure 1 As shown, the ion exchange resin wastewater zero-discharge treatment method provided by the present invention comprises the following steps:

[0023] S01: Anion and cation exchange: waste water is passed into the cation exchanger and anion exchanger in sequence; the acid regeneration waste liquid is extracted by the cation exchanger, and the alkali regeneration waste liquid is extracted by the anion exchanger; the rest is clean ion exchange water. Anion and cation exchange can exchange calcium, magnesium and other ions contained in wastewater. In order to ensure that the hardness of the remaining ion exchanged water is lower than 0.03mmol / L, it is necessary to control the pH of the cation exchanger and anion exchanger between 1- Between 14. The cation exchanger is a hydrogen type cation exchanger filled with strong acid cation resin. After the cations in the wastewater are exchanged with the hydrogen ions in the strongly acidic cation exchange resin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com