Method for cooperatively reducing odor of polyether glycol through catalyst and photo-catalytic oxidation

A polyether polyol, photocatalytic oxidation technology, applied in the field of polymer compound preparation, can solve problems such as polyether polyol odor, achieve good performance, good effect, and reduce the effect of product color and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for synergistically reducing the odor of polyether polyols through binary composite catalysts and photocatalytic oxidation:

[0014] Using ethylenediamine as the starting agent, using a specific binary composite catalyst: potassium ethoxide and zinc glutarate, the mass ratio is 1:1, and the reaction temperature is controlled at 90 o C synthesis polyether polyol. At the same time, in the post-processing process of the product, a titanium dioxide photocatalyst is used to catalyze the oxidation of aldehydes, the amount of the catalyst is 1% of the polyether polyol, and the reaction temperature is controlled at 50 o c.

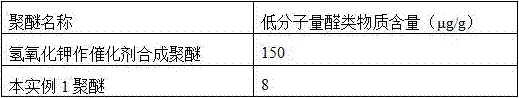

[0015] Attached Table 1 Comparison of the content of aldehydes in the polyether synthesized by the traditional method and the polyether in this example

[0016]

Embodiment 2

[0018] A method for synergistically reducing the odor of polyether polyols through binary composite catalysts and photocatalytic oxidation:

[0019] Using ethylenediamine as the starting agent, using a specific binary composite catalyst: potassium ethylate and zinc glutarate, the mass ratio is 2:1, and the reaction temperature is controlled at 110 o C synthesis polyether polyol. At the same time, in the post-processing process of the product, a titanium dioxide photocatalyst is used to catalyze the oxidation of aldehydes, the amount of the catalyst is 3% of the polyether polyol, and the reaction temperature is controlled at 70 o c. .

[0020] Attached Table 2 Comparison of the content of aldehydes in the polyether synthesized by the traditional method and the polyether in this example

[0021] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com