Radiator of power amplifier

A power amplifier and radiator technology, applied in cooling/ventilation/heating transformation, modification with gaseous coolant, electrical components, etc., can solve the problem of low heat dissipation efficiency, and achieve the effect of simple installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

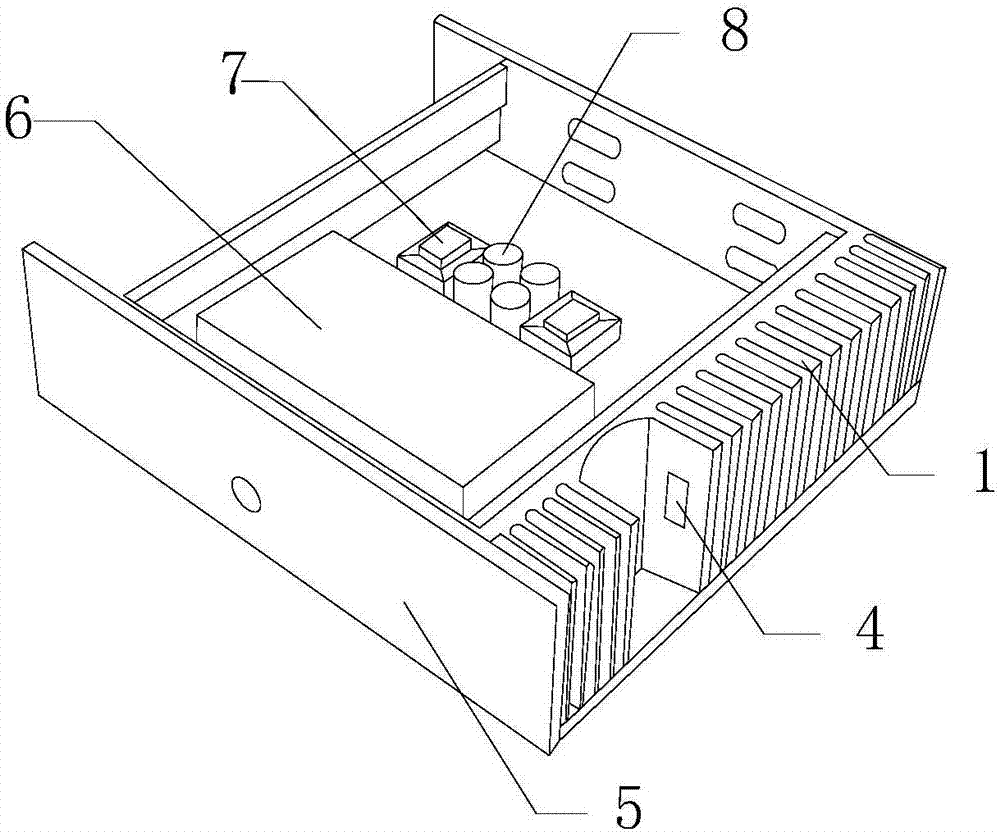

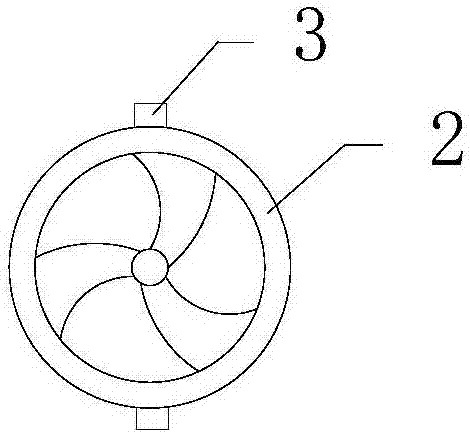

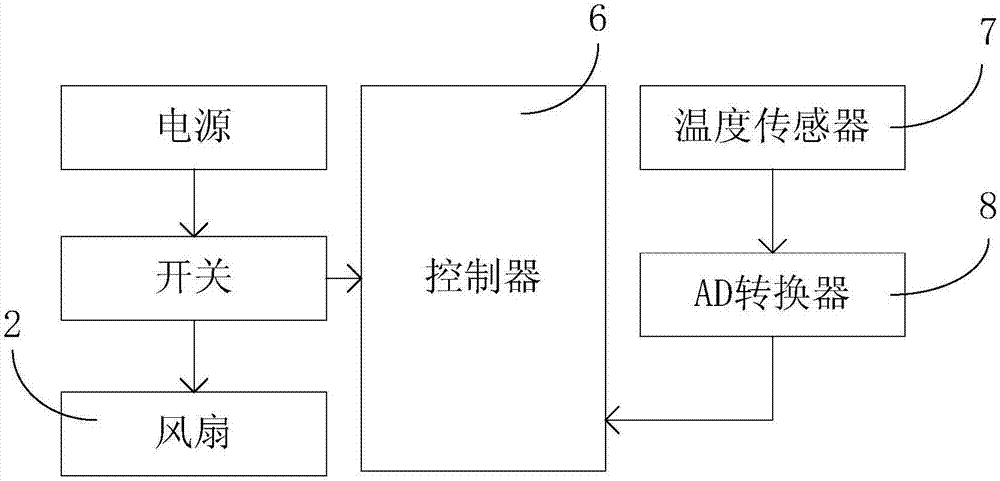

[0025] Such as figure 1 , 2 , shown in 3, a kind of radiator of power amplifier, comprises power amplifier 6, at least 10 heat sinks 1, controller, temperature sensor 7, AD converter 8; side, and an empty slot is arranged between the cooling fins 1, and a fan 2 is arranged in the empty slot; the controller is arranged inside the power amplifier 6; the temperature sensor 7 and the AD converter 8 are all arranged in the power On the other side of the amplifier 6 , the temperature sensor 7 is electrically connected to the AD converter 8 , and the AD converter 8 is electrically connected to the controller, and the controller is electrically connected to the fan 2 . Through the cooperation of the above-mentioned components, a heat dissipation system is formed. First, the temperature sensor 7 monitors the temperature of the power amplifier 6. When the temperature is too high, an alarm signal is sent to the controller through the AD converter 8, so that the controller turns on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com