Dispersible oil suspending agent containing mesosulfuron-methyl and clodinafop-propargyl and preparation method thereof

A technology containing methyldisulfuron and methyldisulfuron, applied in the field of pesticides, can solve problems such as inability to effectively solve weeds in farmland, poor weeding effect, complex grass phase, etc. High-quality, low-residue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

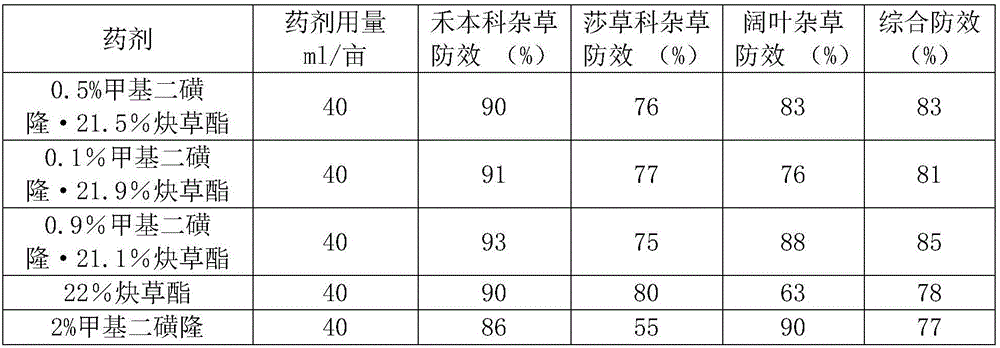

Embodiment 1

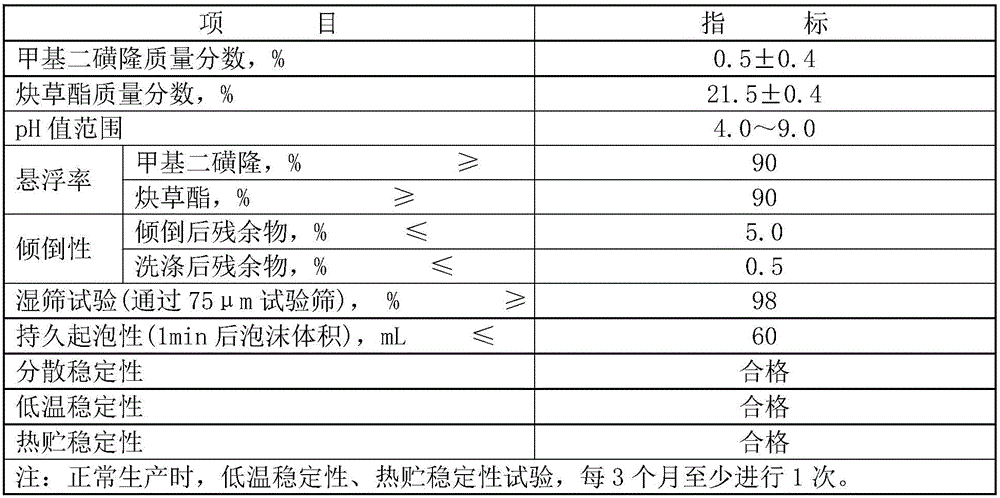

[0028] A kind of clodinafop-propargyl mesosulfuron dispersible oil suspension concentrate, which contains 22% of the total mass fraction of mesulfuron-methyl and clodinafop-propargyl technical; The mass fraction of sulfuron-methyl was 0.9%, and the mass fraction of clodinafop-propargyl was 21.1%.

[0029] Also containing mass fraction in this dispersible oil suspension concentrate is 10% castor oil ethylene oxide, 3% organic bentonite, 8% chloroethylene oxide, 6% lignosulfonate, 5% epoxy soybean oil and 46% deionized water.

Embodiment 2

[0031] A kind of clodinafop-propargyl mesosulfuron dispersible oil suspension concentrate, which contains 22% of the total mass fraction of mesulfuron-methyl and clodinafop-propargyl technical; The mass fraction of sulfuron-methyl technical substance is 0.5%, and the mass fraction of clodinafop-propargyl technical substance is 21.5%.

[0032] Also containing mass fraction in this dispersible oil suspension concentrate is 10% castor oil ethylene oxide, 3% organic bentonite, 8% chloroethylene oxide, 6% lignosulfonate, 5% epoxy soybean oil and 42% deionized water.

Embodiment 3

[0034] A kind of clodinafop-propargyl mesosulfuron dispersible oil suspension concentrate, which contains 22% of the total mass fraction of mesulfuron-methyl and clodinafop-propargyl technical; The mass fraction of sulfuron-methyl was 0.1%, and the mass fraction of clodinafop-propargyl was 21.9%.

[0035] Also containing mass fraction in this dispersible oil suspension concentrate is 10% castor oil ethylene oxide, 3% organic bentonite, 8% chloroethylene oxide, 6% lignosulfonate, 5% epoxy soybean oil and 42% deionized water.

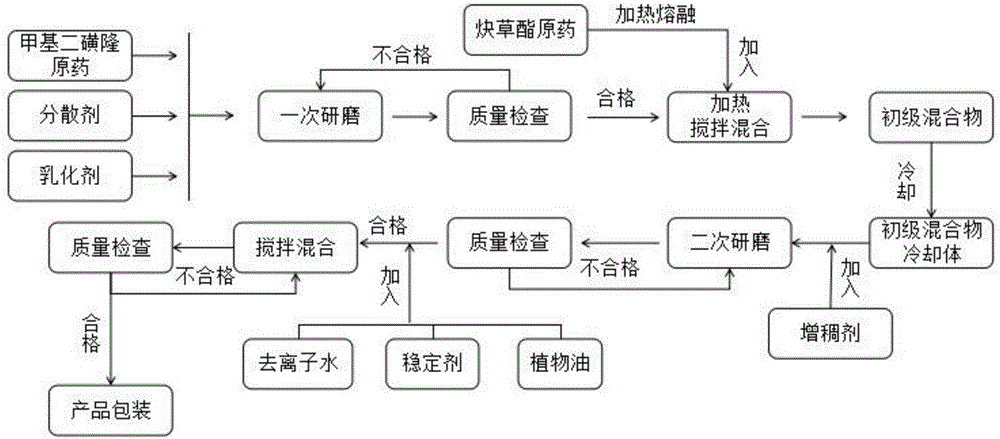

[0036] see figure 1 , processing method of the present invention comprises the following steps:

[0037] In the first step, grind methylsulfuron-methyl, emulsifier and dispersant until the particle size is less than 0.01cm for later use, and heat clodinafop-propargyl to a molten state at 45°C to obtain a melt of clodinafop-propargyl for later use;

[0038] In the second step, the particles of mesosulfuron-methyl, emulsifier and dispersant with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com