Conveying device with loading and unloading device and luggage conveying vehicle

A loading and unloading device and transmission device technology, which is applied in the field of luggage transfer vehicles, can solve the problems of shoulder, waist, and leg injuries of workers, luggage rolling down, and low transition efficiency, so as to improve the stability of luggage and shorten the length of the vehicle , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

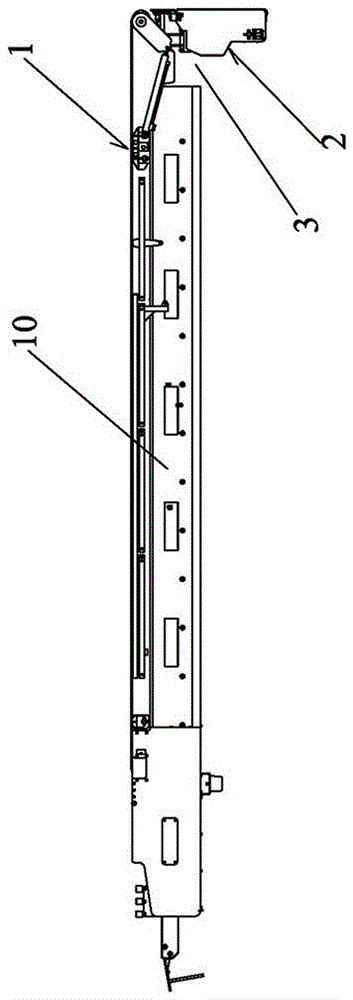

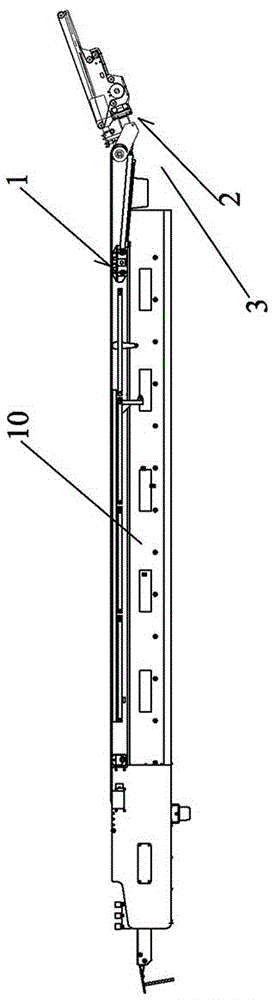

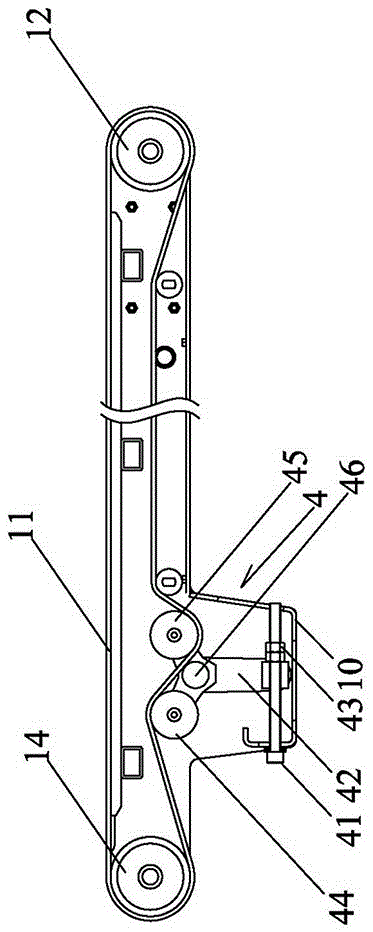

[0035] What the present invention discloses is a kind of conveying device with loading and unloading device, such as figure 1 As shown, it is a preferred embodiment of the present invention. The conveying device is composed of a main conveying device 1 and a loading and unloading device 2 that can be hidden and movably installed at the lower end of the main conveying device 1. Specifically, the loading and unloading device 2 can be pushed and pulled to be hidden in the main conveying device 1. It is hidden under or folded under the main conveying device 1. When luggage conveying is required, the loading and unloading device 2 is pulled out or flipped out, such as figure 2 As shown, on the one hand, the loading stroke of the main conveying device 1 can be extended, and on the other hand, the height of the end of the loading and unloading device 2 can be adjusted so that it can have a better docking with the luggage transfer workshop.

[0036] Among them, such as figure 1 and ...

Embodiment 2

[0041] Such as Figure 10 As shown, a baggage transfer vehicle includes a vehicle and a transfer device with a loading and unloading device as described in Embodiment 1 installed on the vehicle. 1. The loading and unloading device at the lower end is composed of 2. In order to solve environmental problems such as exhaust pollution and noise pollution caused by diesel power, and to avoid the impact of vibration on the stability of the luggage delivery vehicle during engine operation, this embodiment uses an electric vehicle as the main body of the vehicle. Electric automobile comprises headstock 93 and the automobile chassis 94 that is positioned at the headstock rear, and the electric driving device 95 that drives car ahead is fixedly installed on the both sides tops of automobile chassis 94. The lower end of the transmission device is rotatably connected in the middle of the car chassis 94 afterbody, and the main lifting mechanism that can control the lifting of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com