Dimethyl ether carbonylation method, application thereof and reaction equipment for dimethyl ether carbonylation

A dimethyl ether and carbonylation technology, which is applied in the field of dimethyl ether carbonylation and its use and reaction equipment, can solve the problems of high maintenance cost and low production efficiency, and achieve the effect of reducing maintenance cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

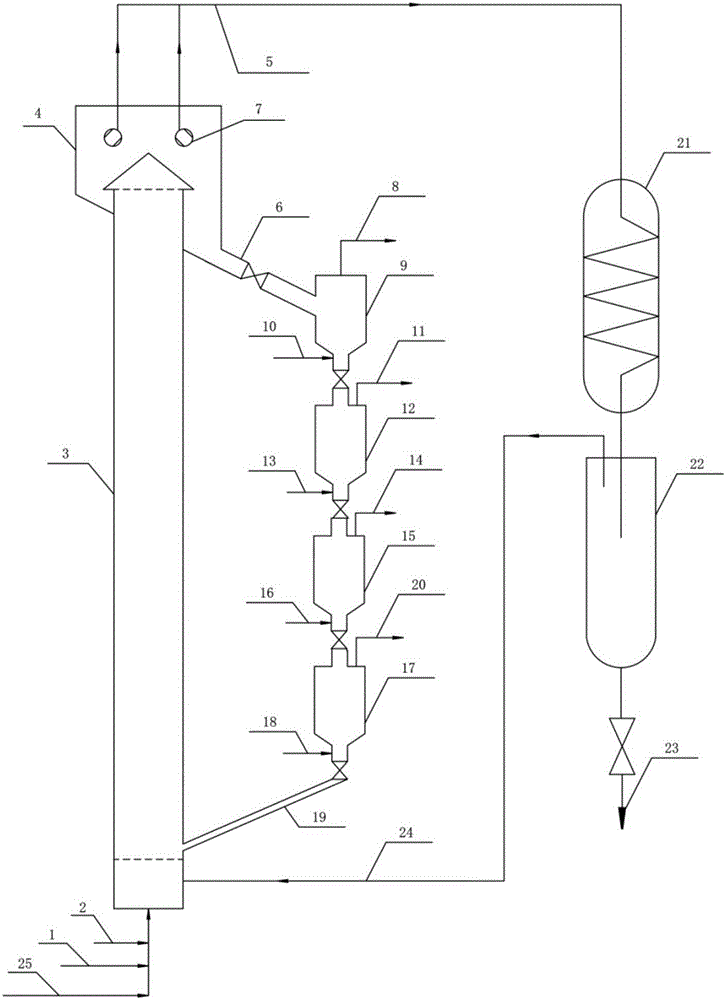

[0060] This embodiment is a method for the carbonylation of dimethyl ether, which includes the following steps: feed the reaction raw materials dimethyl ether, carbon monoxide and hydrogen into the reactor at a space velocity of 2000ml / (g·h), and modify the catalyst-pyridine The dimethyl ether carbonylation reaction is carried out under the action of the hierarchically porous hydrogen-type mordenite molecular sieve, the reaction temperature is 160° C., and the reaction pressure is 3.0 MPa. Among them, the molar ratio of dimethyl ether to carbon monoxide is 1:2, and the molar ratio of hydrogen to carbon monoxide is 1:1. After the reaction is finished, the catalyst is separated from the reaction product, and the separated catalyst is regenerated outside the reactor and then passed into the reactor for reaction. The separated reaction product is sequentially passed through a condenser and a gas-liquid separator to obtain methyl acetate.

Embodiment 2

[0062] The present embodiment is a method for the carbonylation of dimethyl ether. Compared with Example 1, the difference is that the space velocity of feeding dimethyl ether, carbon monoxide and hydrogen is 2500ml / (g h), and all the other are the same as those in Example 1. 1 is the same.

Embodiment 3

[0064] The present embodiment is a method for the carbonylation of dimethyl ether. Compared with Example 1, the difference is that the space velocity of feeding dimethyl ether, carbon monoxide and hydrogen is 3000ml / (g h), and the rest are the same as those in the embodiment. 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com