Scratch-resistant polyamide composition and preparation method thereof

A polyamide composition and a scratch-resistant technology, which are applied in the field of scratch-resistant polyamide compositions and their preparation, can solve the problem of polyamide not being scratch-resistant, and achieve the effect of good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

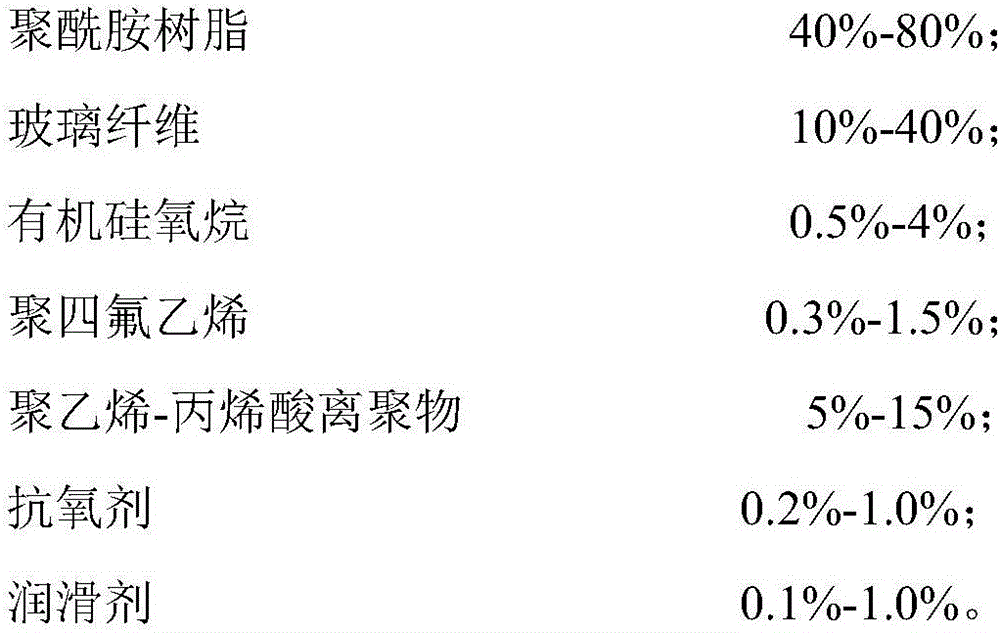

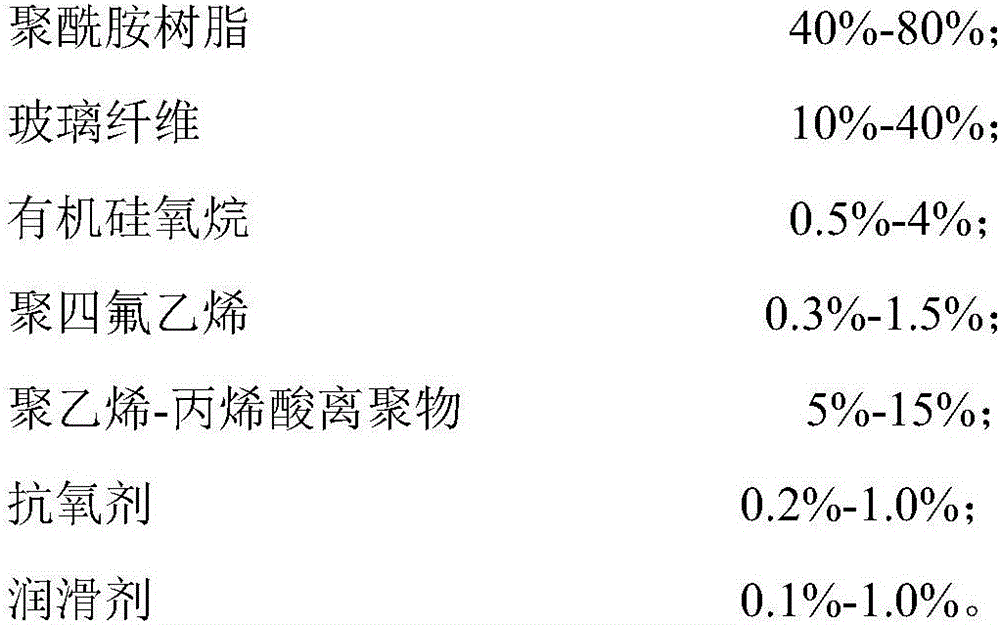

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of scratch-resistant polyamide composition, comprising the following steps:

[0043] 1) Weigh all components except glass fiber in proportion, stir and mix to obtain premix;

[0044] 2) Add the premix to the main feed port of the twin-screw extruder, add glass fiber from the side feed port, and extrude and granulate to obtain a scratch-resistant polyamide composition.

[0045] Preferably, the mixing conditions in step 1) are: temperature: normal temperature; stirring speed: 60-120 rpm; stirring time 1-5 minutes.

[0046] Preferably, the twin-screw extruder in step 2) is a toothed co-rotating parallel twin-screw extruder with an aspect ratio of ≥32:1; further preferably, the aspect ratio of the twin-screw extruder in step 2) It is (36~40):1.

Embodiment 1

[0049] The following raw materials are used:

[0050] Polyamide (PA66EPR27) 74.6kg;

[0051] Glass fiber (ECS301CL-3 alkali-free glass fiber processed by silane coupling from Chongqing International Composite Materials Co., Ltd.) 10kg;

[0052] Organosiloxane (GM100) 4kg;

[0053] Polytetrafluoroethylene (TF9207) 0.4kg;

[0054] Polyethylene-(meth)acrylic acid ionomer (sarin resin 8940) 10kg;

[0055] Antioxidant (Tianjin Rianlong New Materials Co., Ltd. 1098 and 168 are matched at 1:1) 0.5kg;

[0056] Lubricant (Honeywell AC540) 0.5kg.

[0057] Put the components other than the glass fiber into the high-speed mixer according to the weight percentage, and stir for 1-5 minutes under the conditions of normal temperature and 120 r / min to prepare the premix; select the teeth with an aspect ratio of 36:1. Type co-rotating parallel twin-screw extruder, the temperature range of each zone is 245-305 ℃, the premix is fed into the extruder through the main feed port of the twin-s...

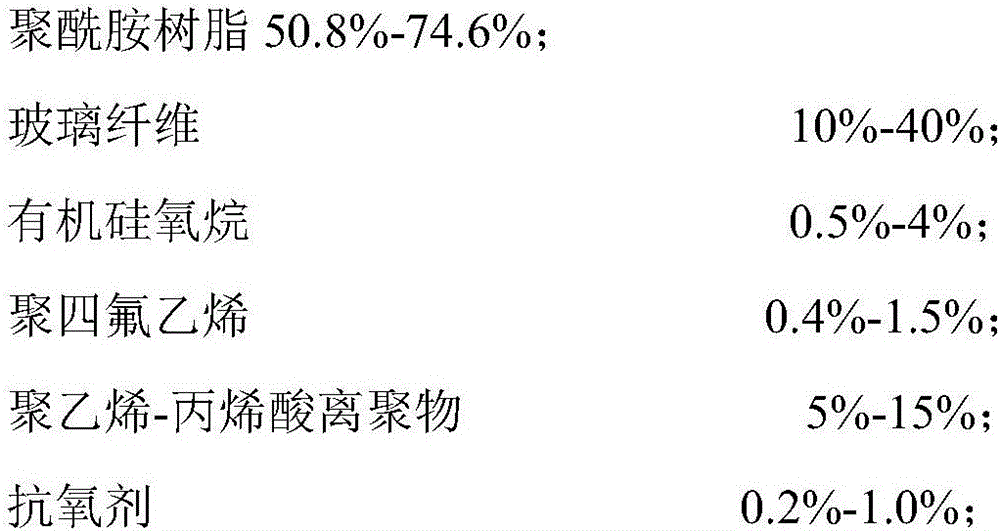

Embodiment 2

[0059] The following raw materials are used:

[0060] Polyamide (PA66EPR27) 50.8kg;

[0061] Glass fiber (ECS301CL-3 alkali-free glass fiber processed by silane coupling from Chongqing International Composite Materials Co., Ltd.) 40kg;

[0062] Organosiloxane (GM100) 2kg;

[0063] Polytetrafluoroethylene (TF9207) 0.6kg;

[0064] Polyethylene-(meth)acrylic acid ionomer (sarin resin 8940) 5kg;

[0065] Antioxidant (Tianjin Rianlong New Materials Co., Ltd. 1098 and 168 are matched at 1:1) 0.6kg;

[0066] Lubricant (Honeywell AC540) 1.0kg.

[0067] Put the components other than the glass fiber into the high-speed mixer according to the weight percentage, and stir for 1-5 minutes under the conditions of normal temperature and 120 r / min to prepare the premix; select the teeth with a length-diameter ratio of 40:1. Type co-rotating parallel twin-screw extruder, the temperature range of each zone is 245-305 ℃, the premix is fed into the extruder through the main feed port of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com