Friction modifier as well as preparation method and application thereof

A friction modifier, extreme pressure additive technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of sintering, workpiece and machining tool wear, contact surface scratches, etc., and achieves simple and easy-to-control process and simple steps. , the effect of good lubricating performance

- Summary

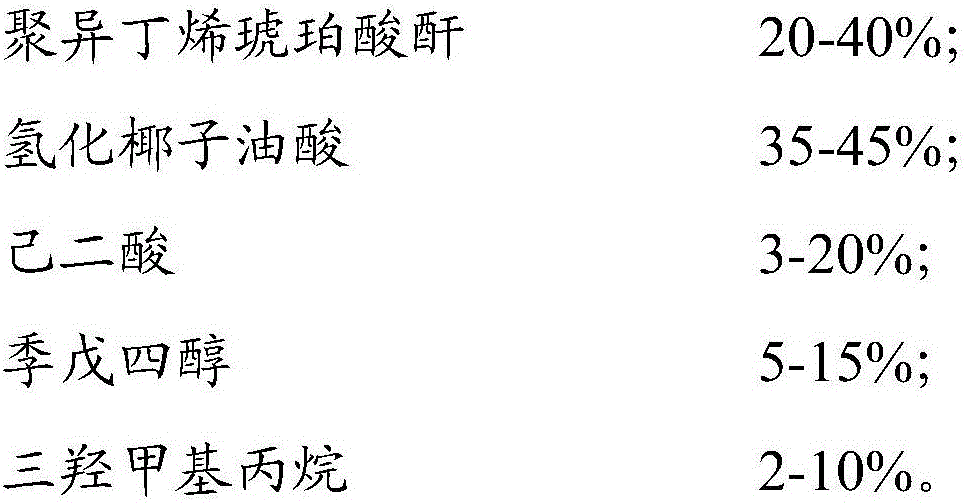

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

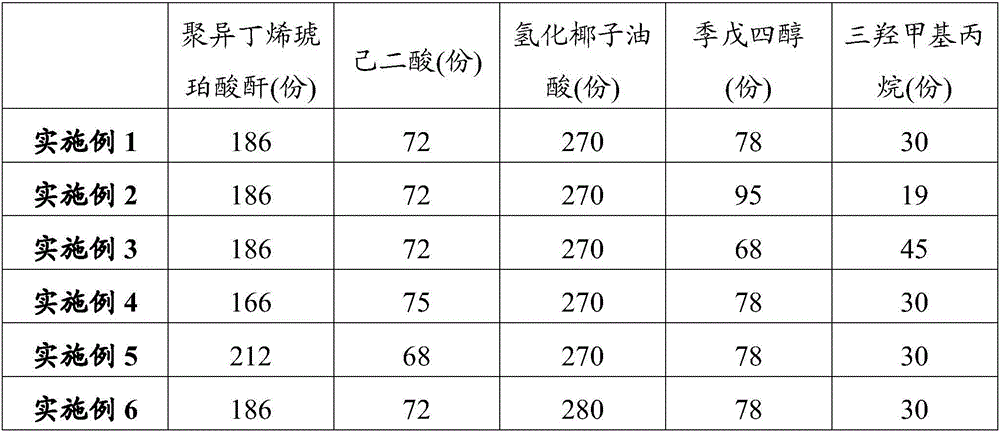

[0034] The friction modifier described in this embodiment includes the following components in parts by weight, as shown in Table 1:

[0035]

[0036] Table 1

[0037] The preparation method of embodiment 1-6 friction modifier specifically comprises the following steps:

[0038] (1) Add polyisobutylene succinic anhydride, hydrogenated coconut oleic acid, adipic acid, pentaerythritol and trimethylolpropane to the reactor, add 0.32 parts by weight of monobutyltin oxide, nitrogen, and heat up;

[0039] (2) When the temperature rises to 130°C, keep increasing the temperature by 10°C per hour;

[0040] (3) When the temperature rises to 200°C, keep the temperature for reaction for 3 hours;

[0041] (4) Vacuumize and react until the pH value of the product is less than 5 and the viscosity is greater than 5500mm 2 / s, the material can be cooled and discharged.

experiment example 1

[0047] In order to evaluate the lubricating effect of the friction modifier of the present invention applied in metalworking oil, this experimental example adopts four-ball test to measure the maximum non-seizing load (P B ), sintering load (P D ), long-term friction wear scar diameter (D). in:

[0048] Maximum non-jamming load (P B ): Measured according to the national standard GB / T 3142-82 lubricant bearing capacity test method; the conditions are as follows: time 10 seconds; speed 1450 rpm; temperature 27±8°C, lock 68±7N m;

[0049] Sintering load (P D ): Measured according to the national standard GB / T 3142-82 lubricant bearing capacity test method; the conditions are as follows: time 10 seconds; speed 1450 rpm; temperature 27±8°C, lock 68±7N m;

[0050] Long-term friction and wear scar diameter (D): measured according to the industry standard SH / T 0189-92 lubricating oil anti-wear performance test method; the conditions are as follows: time 60 minutes; speed 1200 rpm;...

experiment example 2

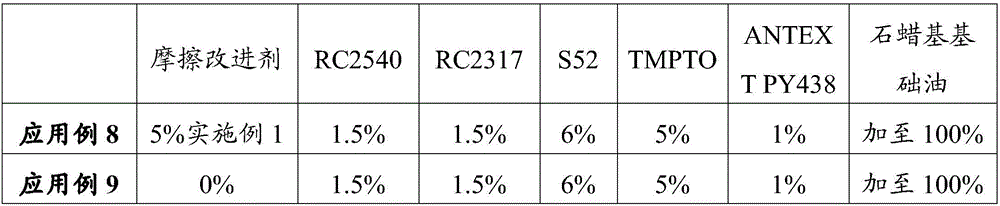

[0073] In order to evaluate the improvement effect of the friction modifier of the present invention on the lubricating performance of commonly used metal processing oil additives, the stainless steel processing oil described in Application Examples 8-9 was subjected to a four-ball test as described in Experimental Example 1, and the UMEMA The special cutting oil for stainless steel provided by Trading (Shanghai) Co., Ltd. is the processing oil used on site for comparison.

[0074] The results are shown in the table below:

[0075] testing sample

P B (kg)

P D (kg)

D(mm)

Application example 8

135

500

0.355

Application example 9

95

355

0.382

On-site processing oil

120

500

0.358

[0076] From the above data analysis, it can be seen that the stainless steel processing oil added with the friction modifier in Embodiment 1 in Application Example 8 of the present invention has a P B The value is 40kg higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com