Polyacetylimine/polydiphenolic acid phenyl phosphate/sodium alginate three-component flame-retardant modified ramie fabric and preparation method thereof

A technology of polybisphenolic acid phenyl phosphate and bisphenolic acid phenyl phosphate is applied in the directions of plant fibers, textiles and papermaking, fiber processing, etc., and can solve problems such as restricting application expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

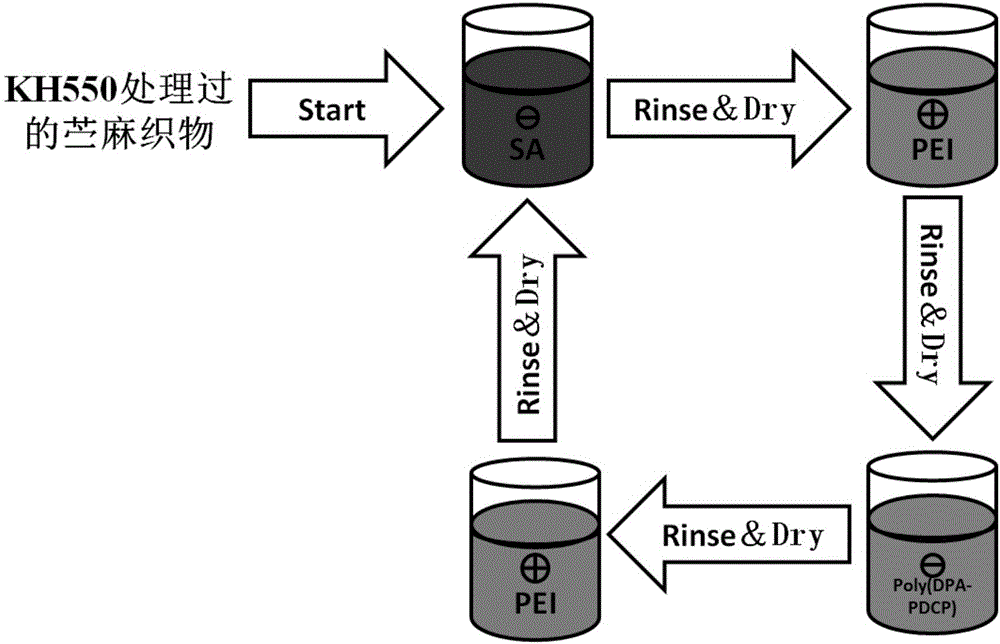

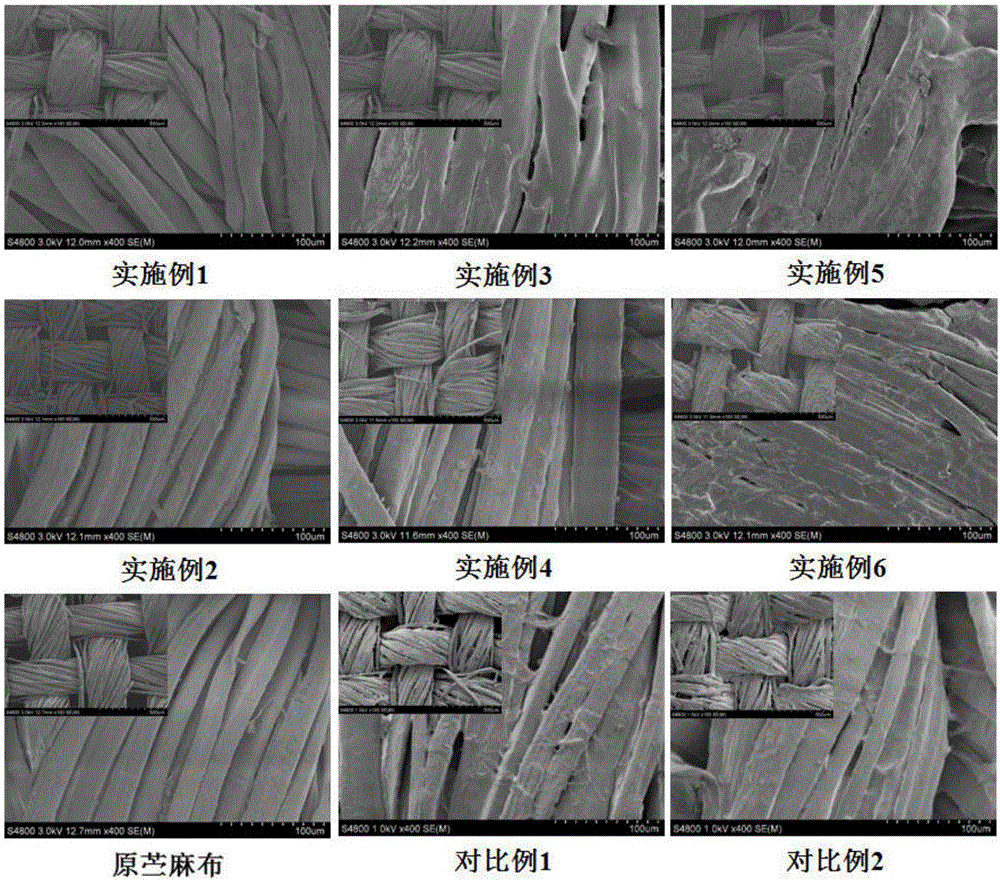

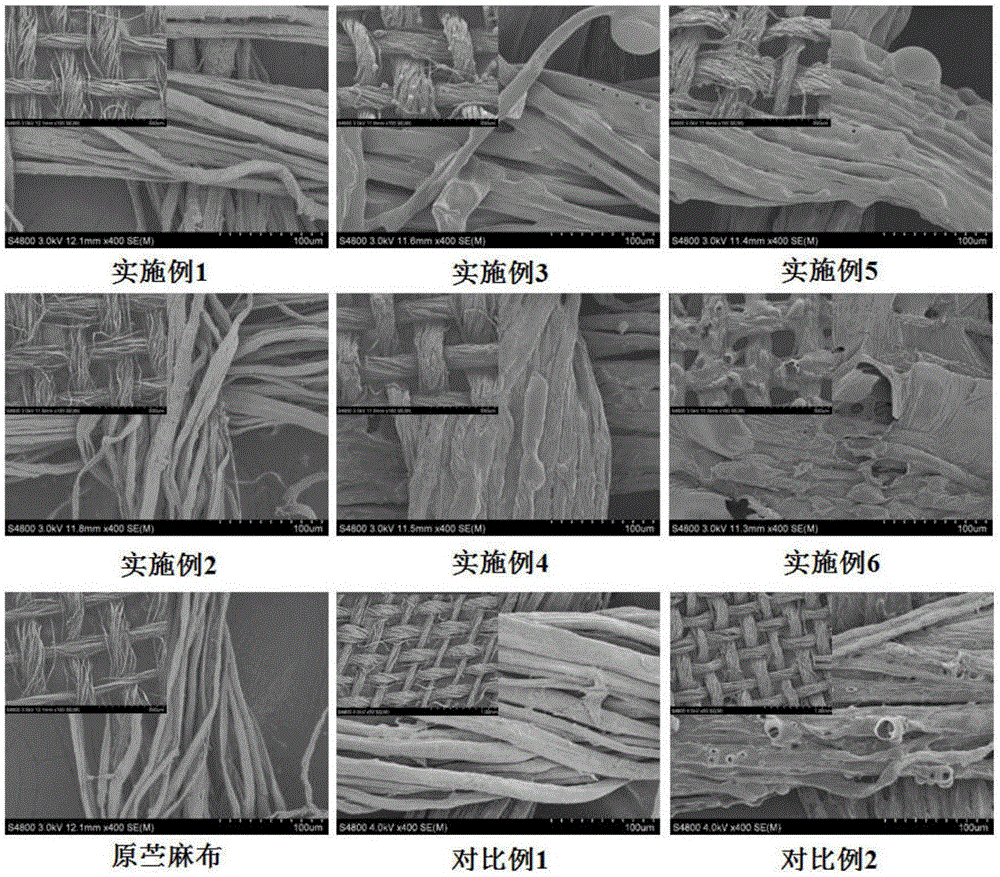

[0037] Soak the ramie fabric in 0.3wt% KH550 solution for 2h, take it out and dry it in a blast dryer at 70°C for 10min. Soak KH550-treated ramie fabric in 0.5wt% SA solution for 5 minutes. Rinse with deionized water for 1 min, and dry in a blast oven at 70°C for 10 min. Then soak in 1.5wt% PEI solution, 1.5wt% poly(DPA-PDCP) solution and 1.5wt% PEI solution in sequence. The soaking time, cleaning and drying process are the same as those for assembling SA flame retardant coating. This is a four-layer ramie fabric for flame retardant finishing. Its preparation process is as figure 1 shown. The obtained ramie fabric is dried. The content of flame retardant coating was calculated as 3.10% by weighing the mass of ramie fabric before and after treatment. The analysis results of the sample by a thermogravimetric analyzer showed that the residual carbon content at 600°C under air conditions was 4.58%. The limiting oxygen index (LOI) of the sample was measured with an oxygen ind...

Embodiment 2

[0039]Soak the ramie fabric in 0.3wt% KH550 solution for 2h, take it out and dry it in a blast dryer at 70°C for 10min. Soak the KH550-treated ramie fabric in a poly(DPA-PDCP) solution with a mass fraction of 1.5wt% for 5 minutes. Rinse with deionized water for 1 min, and dry in a blast oven at 70°C for 10 min. Then soak in 1.5wt% PEI solution, 0.5wt% SA solution and 1.5wt% PEI solution in turn, the soaking time, cleaning and drying process are the same as the assembly poly(DPA-PDCP) flame retardant coating. This is a four-layer ramie fabric for flame retardant finishing. Its preparation process is as figure 1 shown. The obtained ramie fabric is dried. The content of flame retardant coating was calculated as 2.03% by weighing the mass of ramie fabric before and after treatment. The analysis results of the sample by a thermogravimetric analyzer showed that the residual carbon content at 600°C under air conditions was 2.36%. The limiting oxygen index of the sample was meas...

Embodiment 3

[0041] Soak the ramie fabric in 0.5wt% KH550 solution for 2h, take it out and dry it in a blast dryer at 90°C for 5min. The ramie fabric treated with KH550 was soaked in SA solution with a mass fraction of 1.0wt% for 5 minutes. Rinse with deionized water for 1 min, and dry in a blast oven at 90°C for 5 min. Then soak in 2.0wt% PEI solution, 2.0wt% poly(DPA-PDCP) solution and 2.0wt% PEI solution in sequence, the soaking time, cleaning and drying process are the same as assembling SA flame retardant coating. This is a four-layer ramie fabric for flame retardant finishing. Repeat this process until 5 four-layer flame retardant coatings are assembled on the surface of the ramie fabric. The preparation process is as follows: figure 1 shown. The obtained ramie fabric is dried. The content of flame retardant coating was calculated as 22.85% by weighing the mass of ramie fabric before and after treatment. The analysis results of the sample by a thermogravimetric analyzer showed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com