A kind of slope protection prefabricated component concrete containing iron tailings and its preparation method

A technology of prefabricated components and concrete, which is applied in the field of iron-containing tailings slope protection prefabricated component concrete and its preparation, can solve the problems of poor cohesion and the quality problems of slope protection prefabricated components, etc., so as to ensure erosion resistance and good ecology Significance of environmental protection, high durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

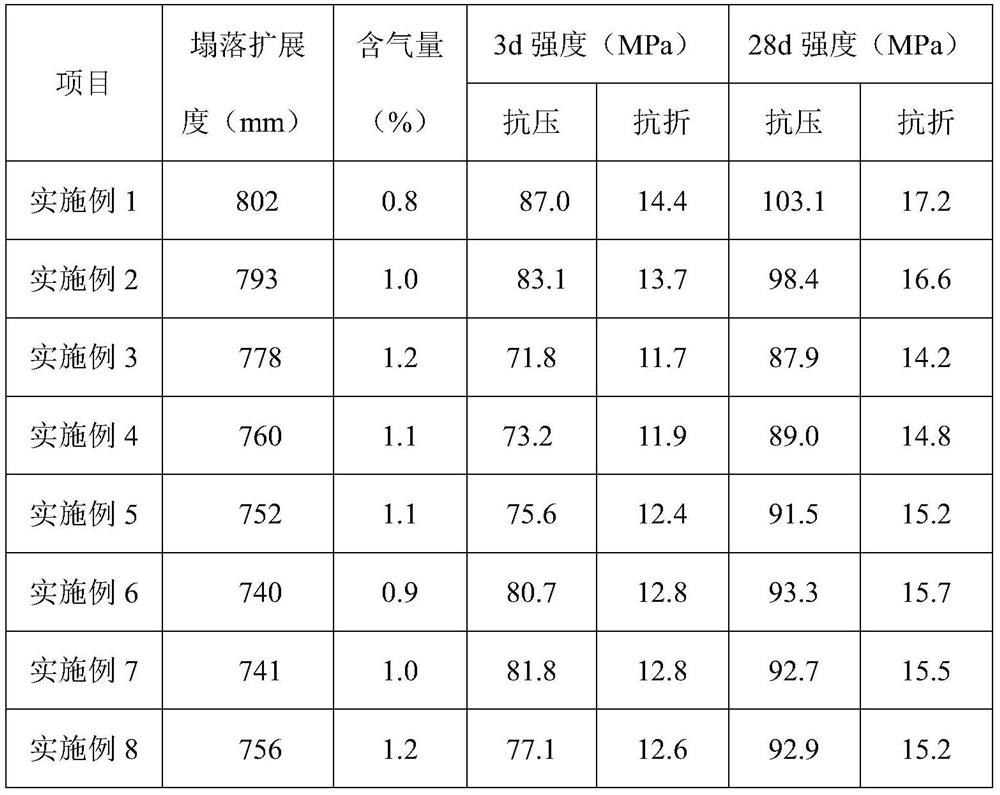

Examples

Embodiment 1

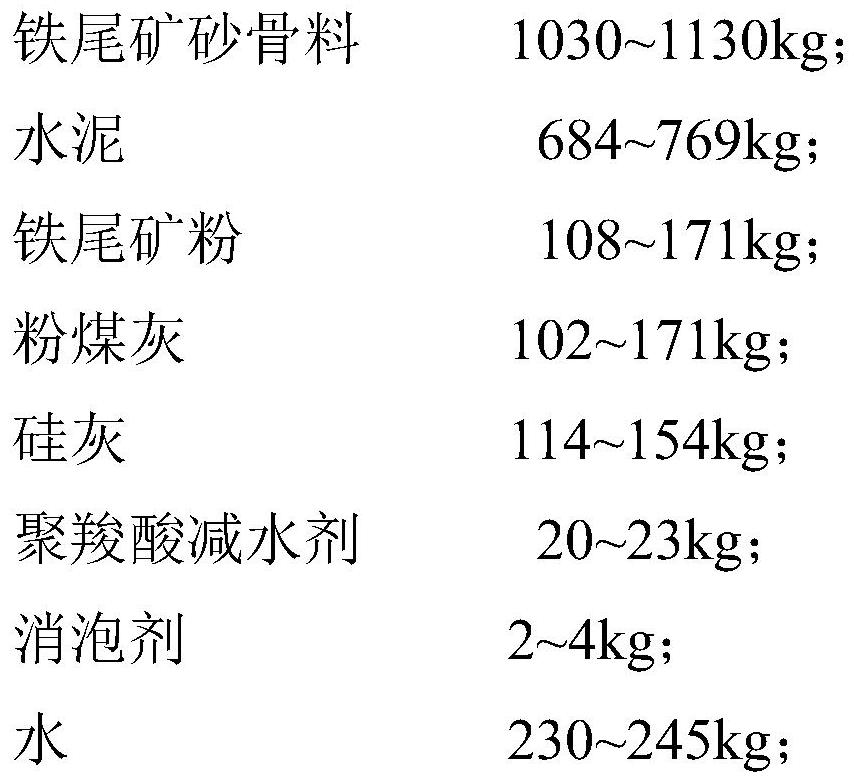

[0034] As shown in Table 1, the slope protection prefabricated component concrete per cubic meter of iron-containing tailings includes the following components:

[0035] Iron tailings sand aggregate 1130kg, cement 769kg, iron tailings powder 120kg, fly ash 102kg, silica fume 154kg, polycarboxylate superplasticizer 20kg, defoamer 3kg, water 245kg.

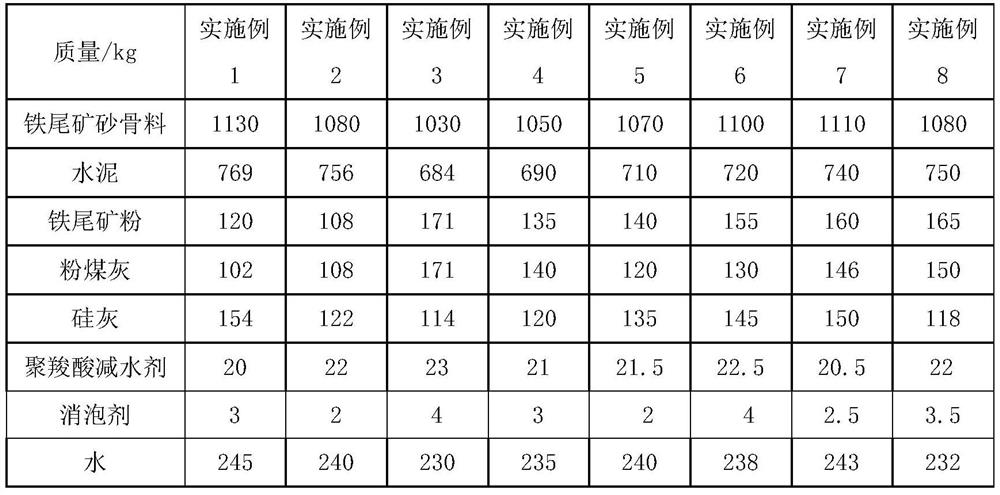

[0036] The composition formula of table 1 embodiment 1-8 concrete

[0037]

Embodiment 2

[0039] As shown in Table 1, the slope protection prefabricated component concrete per cubic meter of iron-containing tailings includes the following components:

[0040] Iron tailings sand aggregate 1080kg, cement 756kg, iron tailings powder 108kg, fly ash 108kg, silica fume 122kg, polycarboxylate superplasticizer 22kg, defoamer 2kg, water 240kg.

Embodiment 3

[0042] As shown in Table 1, the slope protection prefabricated component concrete per cubic meter of iron-containing tailings includes the following components:

[0043] Iron tailings sand aggregate 1030kg, cement 684kg, iron tailings powder 171kg, fly ash 171kg, silica fume 114kg, polycarboxylate superplasticizer 23kg, defoamer 4kg, water 230kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com