Pressure sensor calibration system

A pressure sensor and calibration system technology, applied in the direction of force/torque/work measurement instrument calibration/test, measurement of fluid pressure, instruments, etc., can solve problems such as the absence of pressure sensors, achieve fewer measurement points, and enhance prediction and forecasting capabilities and statistical control effect, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described further:

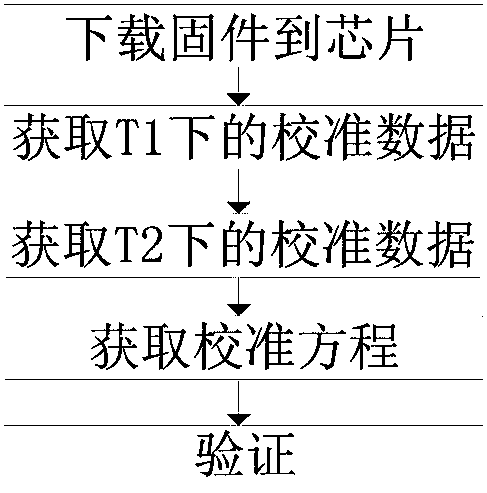

[0024] Such as figure 1 As shown, the implementation flow chart of the pressure sensor calibration system described in the patent of the present invention includes the following processes:

[0025] Download the firmware to the chip.

[0026] Set the ambient temperature point as T1, under this ambient temperature, set the pressure points as P1T1, P2T1 and P3T1 respectively, measure and save the corresponding sensor output voltage and power supply voltage.

[0027] Set the ambient temperature point as T2, under this ambient temperature, set the pressure points as P1T2, P2T2 and P3T2 respectively, measure and save the corresponding sensor output voltage and power supply voltage.

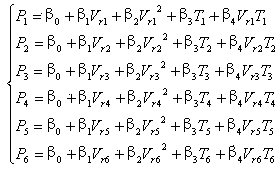

[0028] Calculate the pressure coefficient to be solved according to the multiple regression equation model and the calibration data obtained above, and obtain the calibration equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com