Semiconductor device, manufacture method for the same and electronic device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electric solid devices, circuits, etc., can solve problems such as high difficulty, increased cost, and increased device manufacturing cost, and achieve low cost, reduced manufacturing cost, and reduced manufacturing process difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The following will refer to Figure 3A ~ Figure 3D A method for fabricating a semiconductor device according to an embodiment of the present invention will be described in detail.

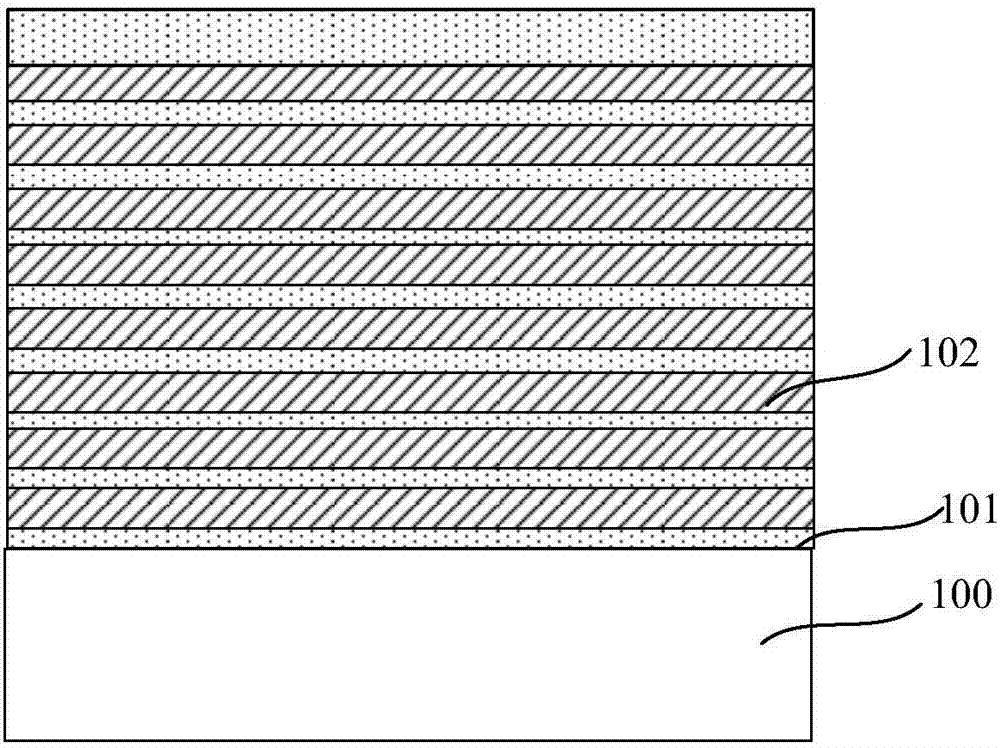

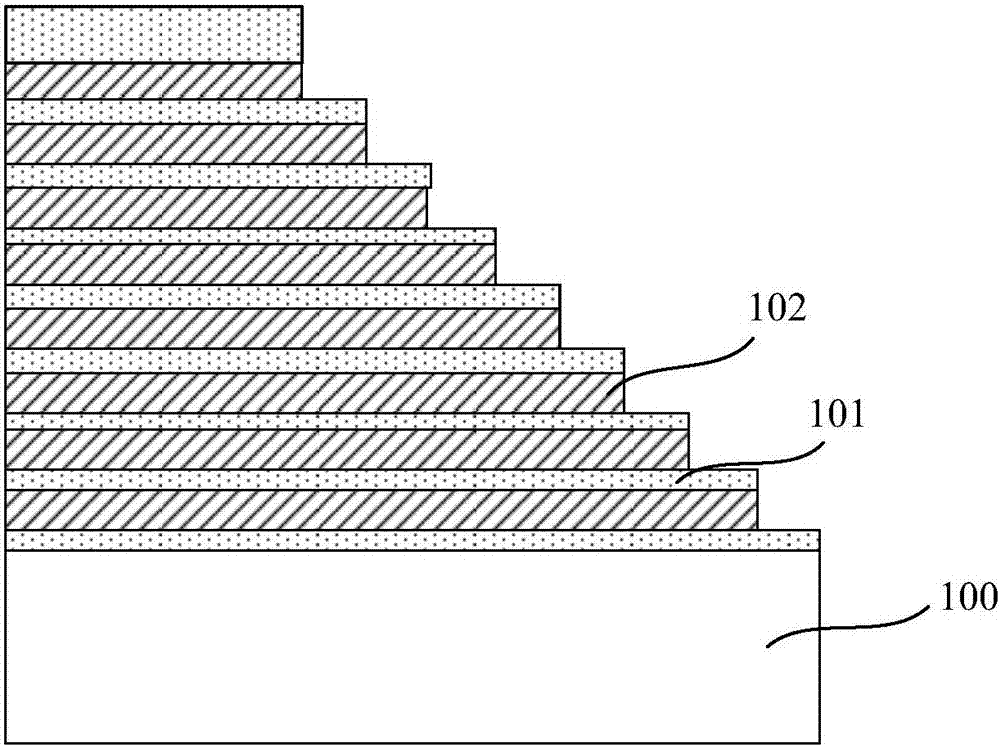

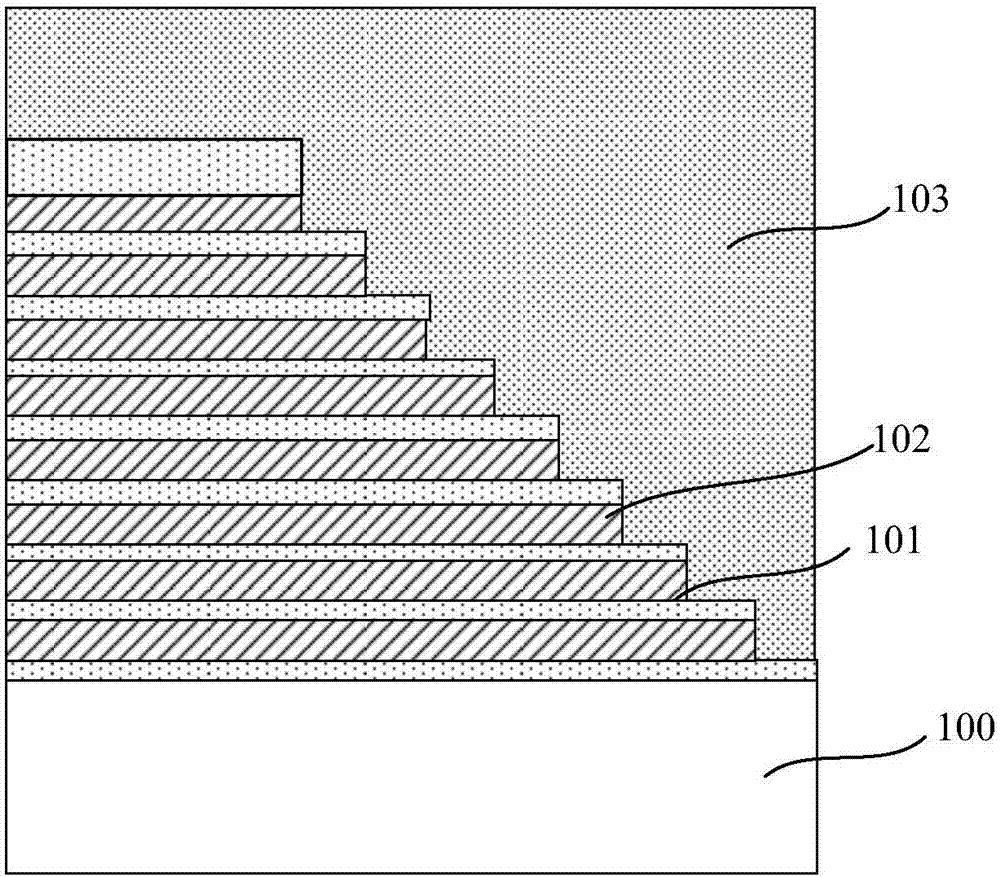

[0051] First, if Figure 3A As shown, a semiconductor substrate 300 is provided. The semiconductor substrate 300 is at least divided into a storage area and a contact plug area. A multilayer stack structure is formed on the semiconductor substrate in the storage area, and each stack structure includes a dielectric layer. 301 and the control gate layer 302 above the dielectric layer 301 . A first dielectric layer 303 covering the multilayer stack structure and the contact plug region is formed on the semiconductor substrate 300, and a patterned hard mask is formed on the first dielectric layer 303 Layer 304.

[0052] Wherein, the semiconductor substrate 300 can be at least one of the materials mentioned below: Si, Ge, SiGe, SiC, SiGeC, InAs, GaAs, InP or other III / V compound semiconductors...

Embodiment 2

[0071] The present invention also provides a semiconductor device fabricated by the above method, such as Figure 4 As shown, the semiconductor device includes: a semiconductor substrate 400, the semiconductor substrate 400 is at least divided into a storage area and a contact plug area, a multi-layer stack structure is formed on the semiconductor substrate in the storage area, each stack The layer structure includes a dielectric layer 401 and a control gate layer 402 located above the dielectric layer 401; a first dielectric layer 403, the first dielectric layer 403 covers the multi-layer stack structure and the contact plug area, in the A plurality of first contact plugs 404 corresponding to the control gate layers in the multilayer stack structure are formed in the first dielectric layer 403 in the contact plug region, and the first contact plugs 404 are formed by each The control gate layer extends obliquely to the upper surface of the first dielectric layer 403; the secon...

Embodiment 3

[0079] Still another embodiment of the present invention provides an electronic device, including a semiconductor device and an electronic component connected to the semiconductor device. Wherein, the semiconductor device includes: a semiconductor substrate, the semiconductor substrate is at least divided into a storage area and a contact plug area, a multi-layer stack structure is formed on the semiconductor substrate in the storage area, and each stack structure includes A dielectric layer and a control gate layer located above the dielectric layer; a first dielectric layer, the first dielectric layer covers the multilayer stack structure and the contact plug area, and the first contact plug area in the contact plug area A plurality of first contact plugs corresponding to the control gate layers in the multi-layer stack structure are formed in a dielectric layer, and the first contact plugs extend obliquely from each of the control gate layers to the first The upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com