Methanol filter

A filter and methanol technology, applied in chemical instruments and methods, combined devices, solid separation, etc., can solve problems that are difficult to detect and have no methanol filtration system, and achieve cleanliness protection and service life, good cleanliness and The effect of service life and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

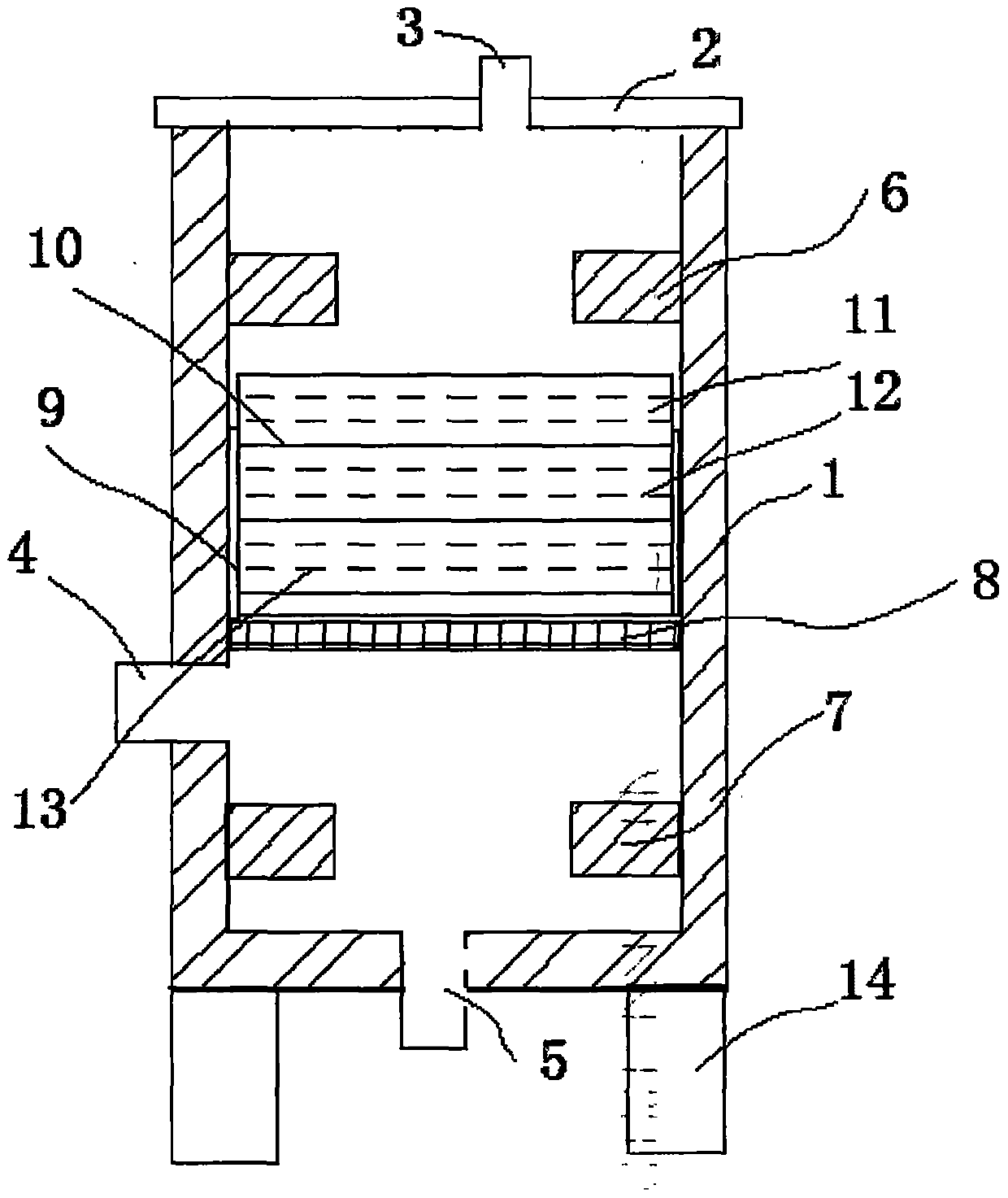

[0012] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

[0013] See figure 1 , a methanol filter, comprising a housing 1 with a hollow cavity, the upper end of the housing is open, the upper opening is provided with a sealing cover 2, the sealing cover is provided with an air outlet 3, the The lower part of the housing is provided with an air inlet 4, the bottom of the housing is provided with a sewage outlet 5, and the hollow inner cavity is sequentially provided with a first ring magnet 6, an activated carbon filter adsorption layer, and a filter filter layer from top to bottom. The cotton layer 8 and the second ring magnet 7, the first and second ring magnets are respectively separated from the activated carbon filter adsorption layer and the filter cotton layer by a preset distance.

[0014] The activated carbon filter adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com