Device and method for increasing hot-pressing speed of shaving board

A technology of particleboard and shavings, which is applied in the pretreatment of molding materials, wood processing equipment, manufacturing tools, etc., to achieve the effect of accelerating transmission, realizing rapid production of particleboard, and realizing rapid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

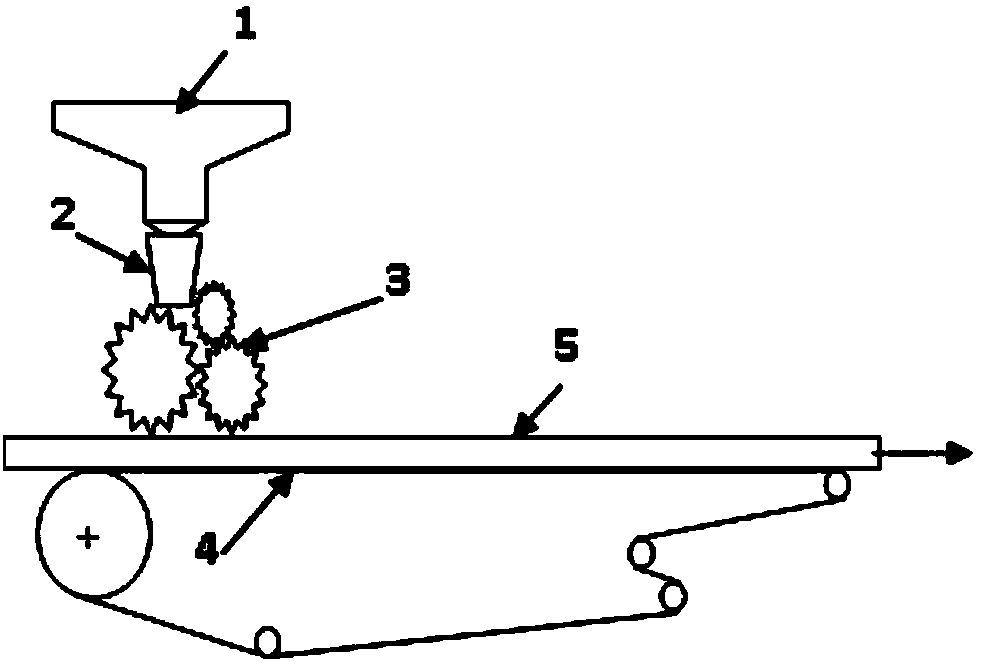

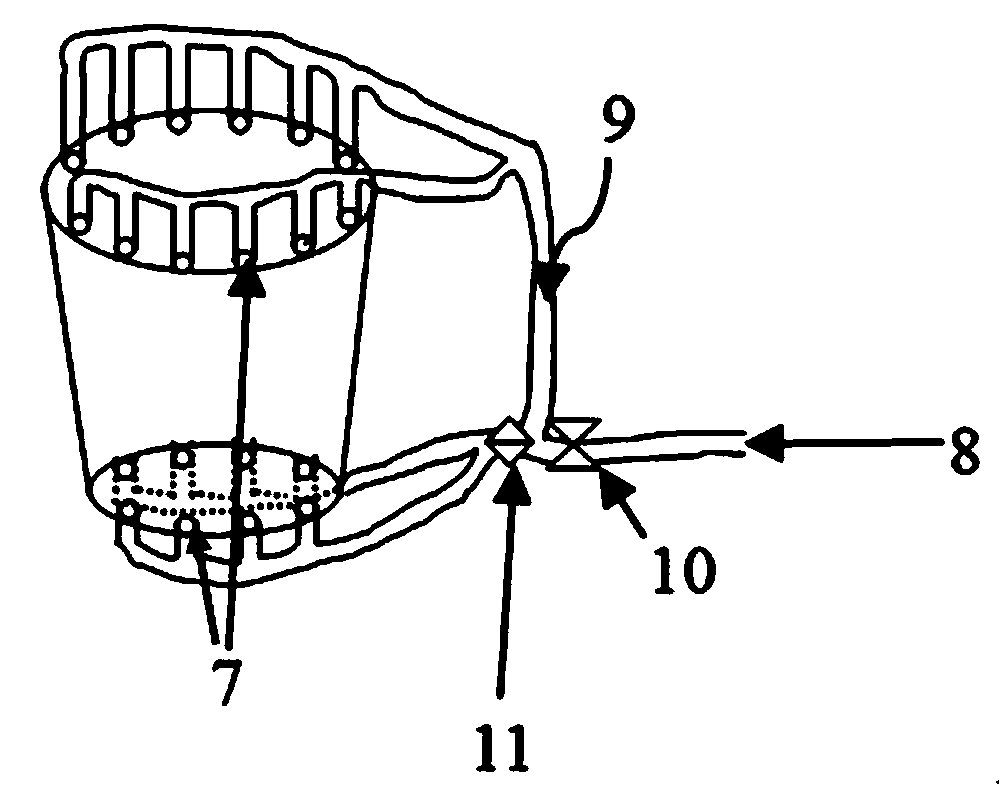

[0029]A device for increasing the hot-pressing speed of particle boards, which includes a core layer shaving bin 1, the bottom of the core layer shaving bin 1 communicates with a hot air treatment device 2, and a paving roller 3 is arranged under the hot air treatment device 2 , a conveyor belt 4 is arranged below the paving roller 3, a slab 5 is arranged on the conveyor belt 4, a hot air pipeline 6 is arranged on the hot air treatment device 2, and a ring with hot air entering the inside of the hot air treatment device 2 is installed. The hot air recovery pipe 9 in the hole 7, under the action of negative pressure, the hot air recovery pipe 9 recycles the hot air through the hot air inlet hole 7. In the hot air recovery pipe 9, the hole spacing of the hot air inlet hole 7 is 10mm , the hole diameter is 5mm, the hot air recovery pipeline 9 communicates with the bottom end of the hot air treatment device 2 and the hot air source 8, the hot air recovery pipeline 9 is provided wit...

Embodiment 2

[0037] A device for increasing the hot-pressing speed of particle boards, which includes a core layer shaving bin 1, the bottom of the core layer shaving bin 1 communicates with a hot air treatment device 2, and a paving roller 3 is arranged under the hot air treatment device 2 , a conveyor belt 4 is arranged below the paving roller 3, a slab 5 is arranged on the conveyor belt 4, a hot air pipeline 6 is arranged on the hot air treatment device 2, and a ring with hot air entering the inside of the hot air treatment device 2 is installed. The hot air recovery pipe 9 in the hole 7, under the action of negative pressure, the hot air recovery pipe 9 recycles the hot air through the hot air inlet hole 7. In the hot air recovery pipe 9, the hole spacing of the hot air inlet hole 7 is 9mm , the hole diameter is 4mm, the hot air recovery pipeline 9 communicates with the bottom end of the hot air treatment device 2 and the hot air source 8, the hot air recovery pipeline 9 is provided wit...

Embodiment 3

[0045] A device for increasing the hot-pressing speed of particle boards, which includes a core layer shaving bin 1, the bottom of the core layer shaving bin 1 communicates with a hot air treatment device 2, and a paving roller 3 is arranged under the hot air treatment device 2 , a conveyor belt 4 is arranged below the paving roller 3, a slab 5 is arranged on the conveyor belt 4, a hot air pipeline 6 is arranged on the hot air treatment device 2, and a ring with hot air entering the inside of the hot air treatment device 2 is installed. The hot air recovery pipe 9 in the hole 7, under the action of negative pressure, the hot air recovery pipe 9 recycles the hot air through the hot air inlet hole 7. In the hot air recovery pipe 9, the hole spacing of the hot air inlet hole 7 is 9mm , the hole diameter is 4mm, the hot air recovery pipeline 9 communicates with the bottom end of the hot air treatment device 2 and the hot air source 8, the hot air recovery pipeline 9 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com