supercavitation surface speed craft

A technology of high-speed boats and supercavitation, which is applied to the construction of ships, hulls, and ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

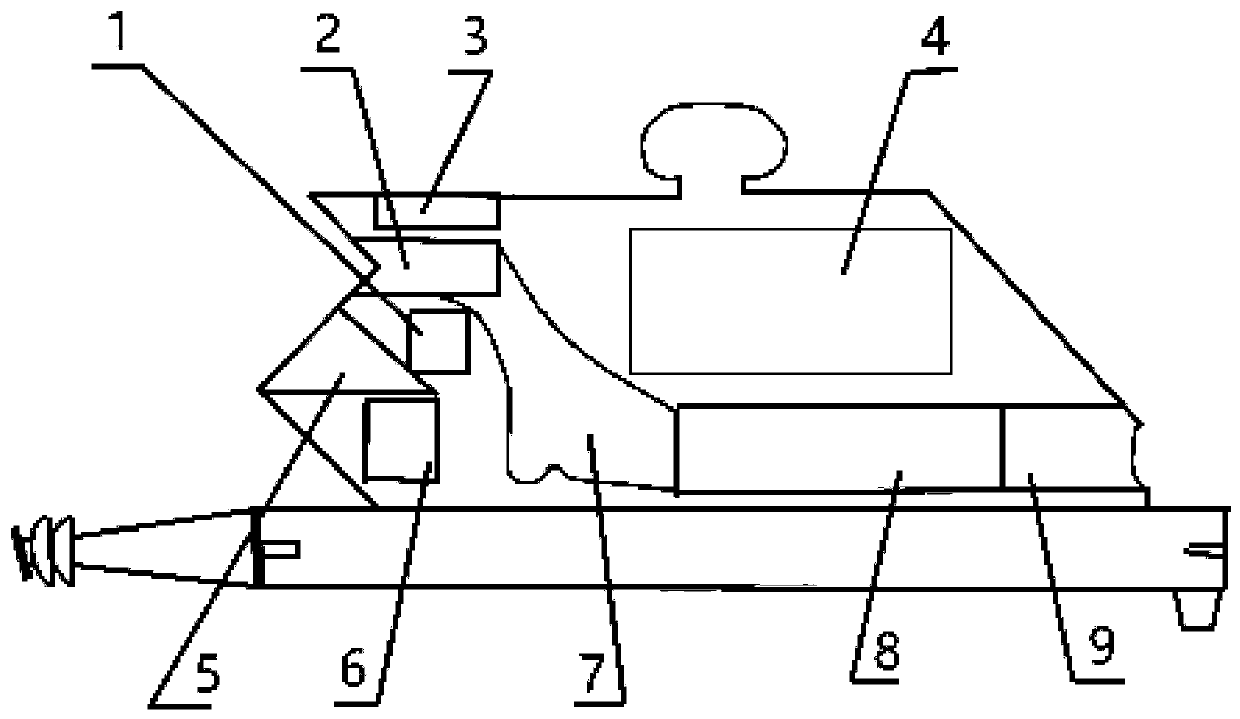

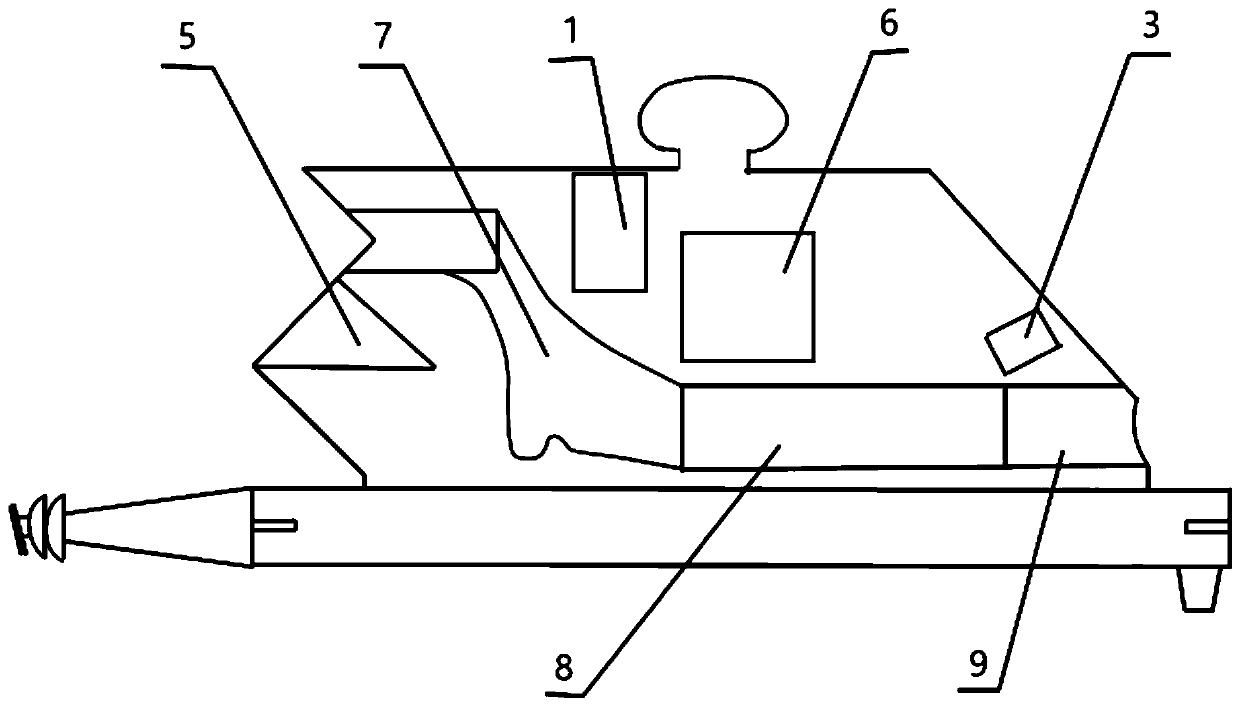

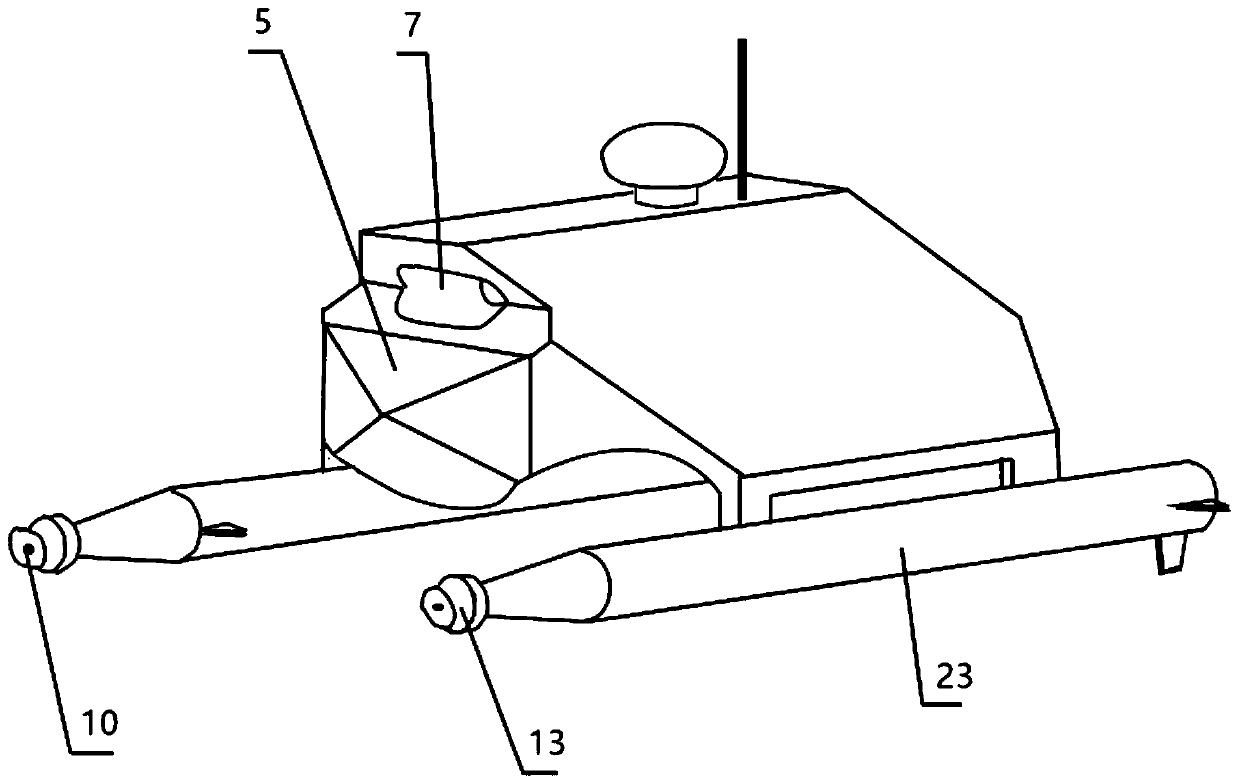

[0017] Carry out the layout and technical design of the supercavitating surface high-speed craft according to the set specific ship outline dimensions (such as length: 20 meters, width: 12 meters, draft: 2.5 meters), and sailing speed (such as 80-100 knots) . The specific implementation is as follows:

[0018] The structure of the supercavitating surface high-speed craft:

[0019] The underwater submersible body is designed, according to the resistance of the supercavitation surface high-speed boat during supercavitation navigation, the shape of the cavitation, and the buoyancy generated when the non-supercavitation state sails and is stationary, the length of the underwater submersible body, Maximum diameter and cavitation diameter. Considering the stability of sailing, set fins and rudders.

[0020] The support structure is designed, the upstream surface is designed to be streamlined, and the inner cavity is convenient for the pipeline of the superstructure to pass to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com