Multi-point combined accurate aeration control method

A control method and combined technology, applied in water aeration, chemical instruments and methods, complex mathematical operations, etc., can solve problems such as poor control effect, inaccuracy, waste of energy aeration, etc., and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

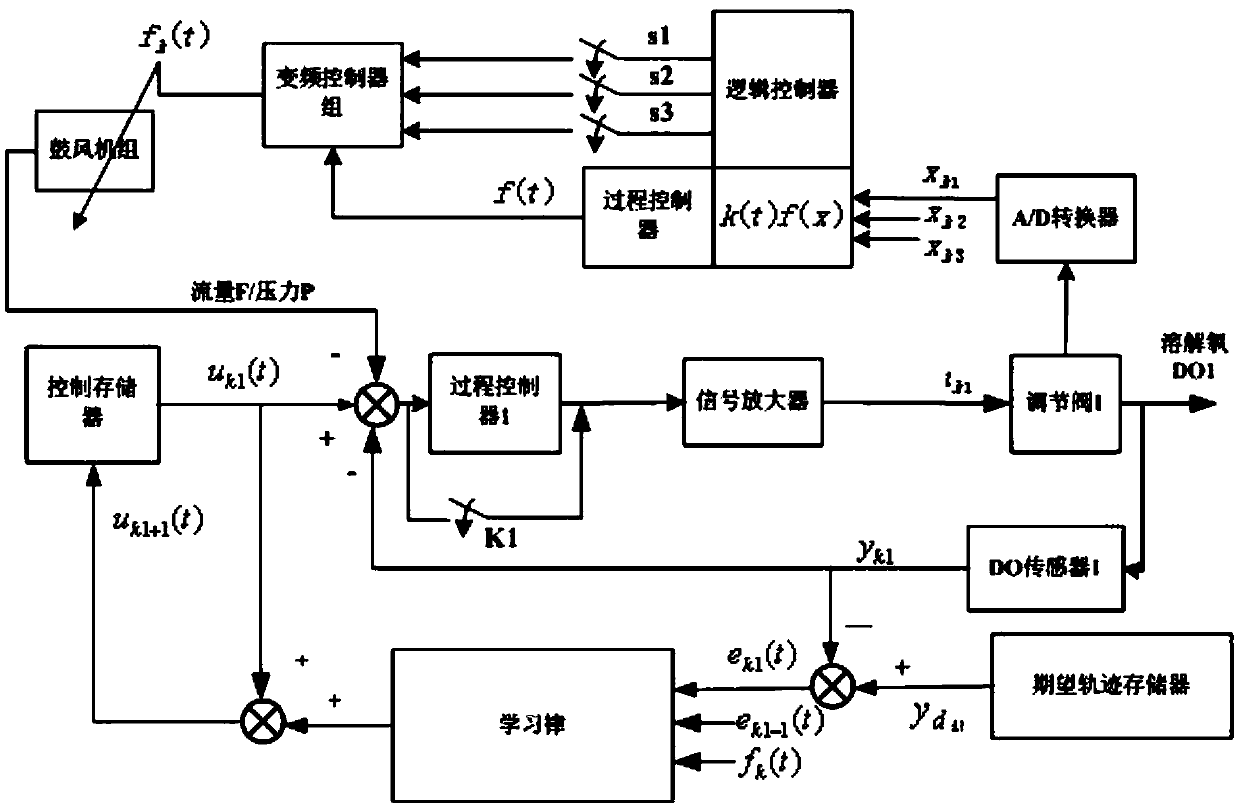

Method used

Image

Examples

Embodiment 1

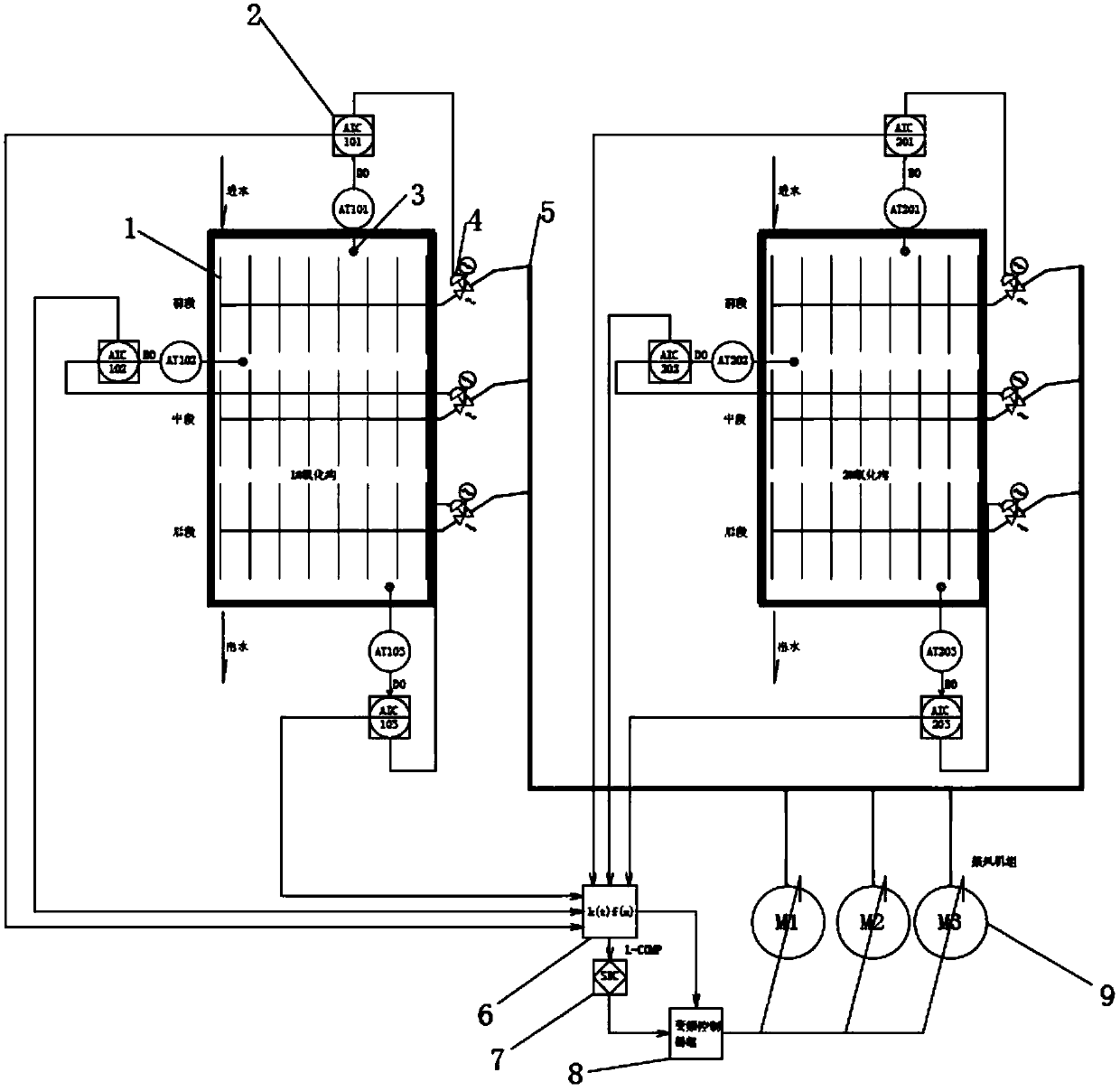

[0030] From figure 1 and figure 2 It can be seen that a multi-point combined precise aeration control method in this embodiment includes a control system including multiple biochemical tanks, a number of aerators 1, a number of partition controllers 2, a number of dissolved oxygen measuring instruments 3, and a number of regulating valves. 4. A number of aeration air main pipes 5, a number of weighted calculators 6, a number of process controllers and logic controllers 7, a number of frequency conversion controllers 8 and a number of blower combination kits 9, the following steps are adopted:

[0031] Step 1: First, for a single biochemical pool, install at least three sets of aerators in the biochemical pool, and install them in the front, middle and back sections according to the water inlet direction, or in the outer, middle and inner ditch;

[0032] Step 2: Then install the actuator regulating valve at the total air inlet of each group of aerators;

[0033] Step 3: Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com