A method for manufacturing flaky rare earth permanent magnet ferrite material

A technology of permanent ferrite and flaky crystals, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems affecting magnetic properties, reduction of local anisotropy field in ball milling, etc., and achieve molding flow Good performance, good for orientation and improved magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for manufacturing flaky rare earth permanent magnet ferrite material, comprising the following steps:

[0024] (1) Pre-burning: Preliminarily ball mill the permanent magnet ferrite billet in a ball mill. In the ball mill, according to the mass ratio, the permanent magnet ferrite billet: steel ball: water = 1:2:1.2; and then undergo microwave under oxygen-enriched conditions. Pre-firing, the microwave frequency is 500~800MHz, the microwave sintering temperature is 1000°C, and the microwave treatment time is 20~25min to generate permanent magnet ferrite pre-sintered material;

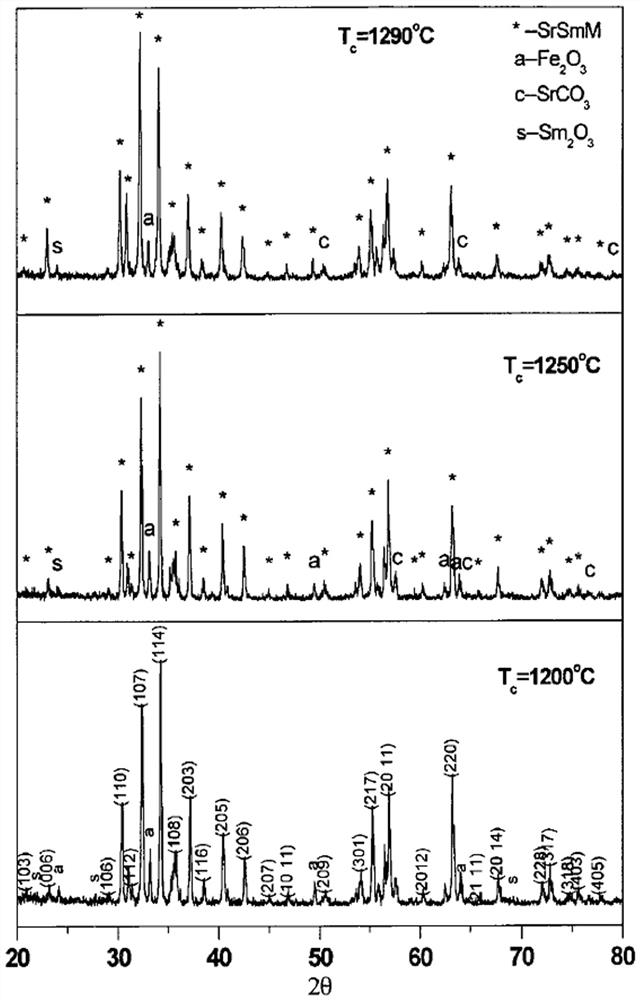

[0025] The permanent magnet ferrite blank is made of SrCO 3 , Fe 2 o 3 and Sm 2 o 3 Composition, according to relative molar ratio, SrCO 3 : Fe 2 o 3 : Sm 2 o 3 =9:56:1.

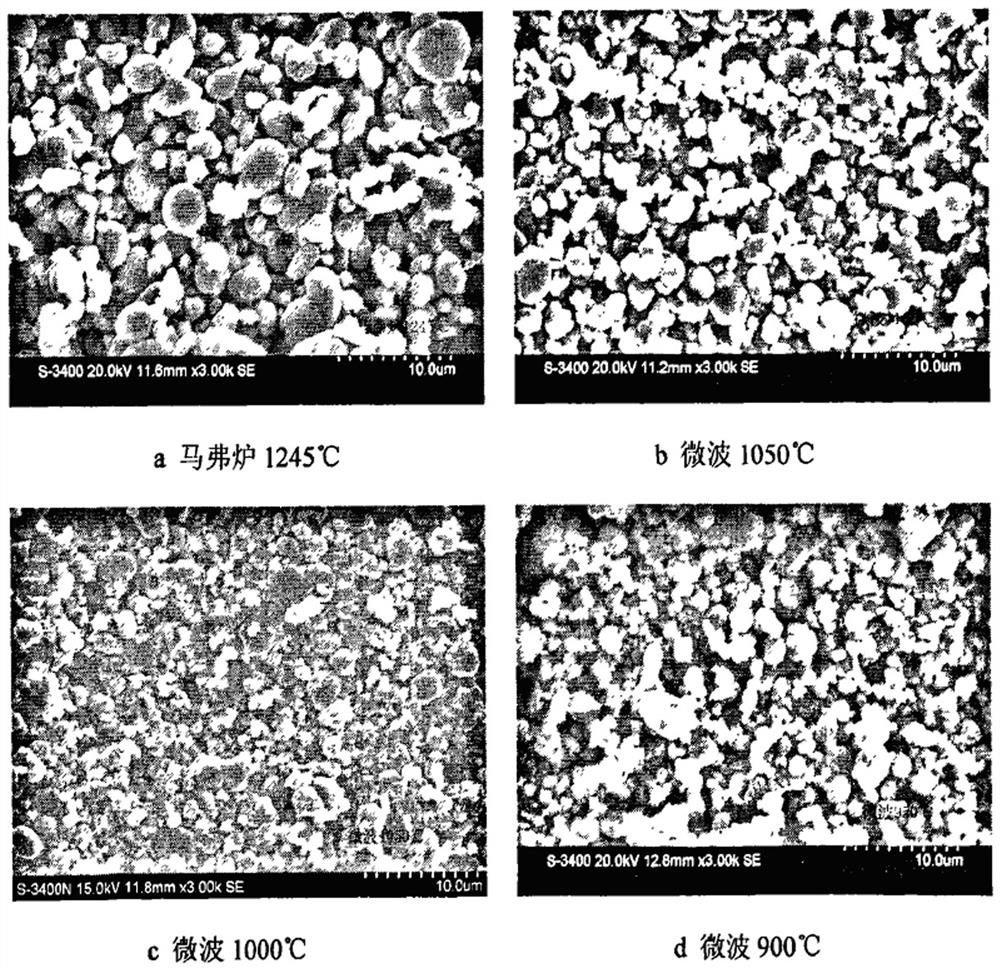

[0026] from figure 1 It can be seen that microwave sintering can significantly reduce the grain size of sintered body compared with conventional muffle furnace sintering. In the traditional sintered samples, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com