Environment-friendly super-black dye based ink

An environmentally friendly ink technology, applied in ink, dyeing, textiles and papermaking, etc., can solve problems such as poor fastness and insufficient depth, and achieve the effect of improving coloring rate and excellent color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take by weighing 12g brown black disperse ink (3g Disperse Yellow 54, 2.5gDisperse Blue 359, 6.5g Disperse Brown 27) and 38g original black disperse ink (8.7g Disperse Yellow 54, 11.4gDisperse Blue 359, 5.7g Disperse Orange 25, 12.2g Disperse Violet 13), add 50g diluent made from clear oil, methanol, isobutanol (1:3:1) and mix, stir evenly with a glass rod to prepare extra black ink color paste.

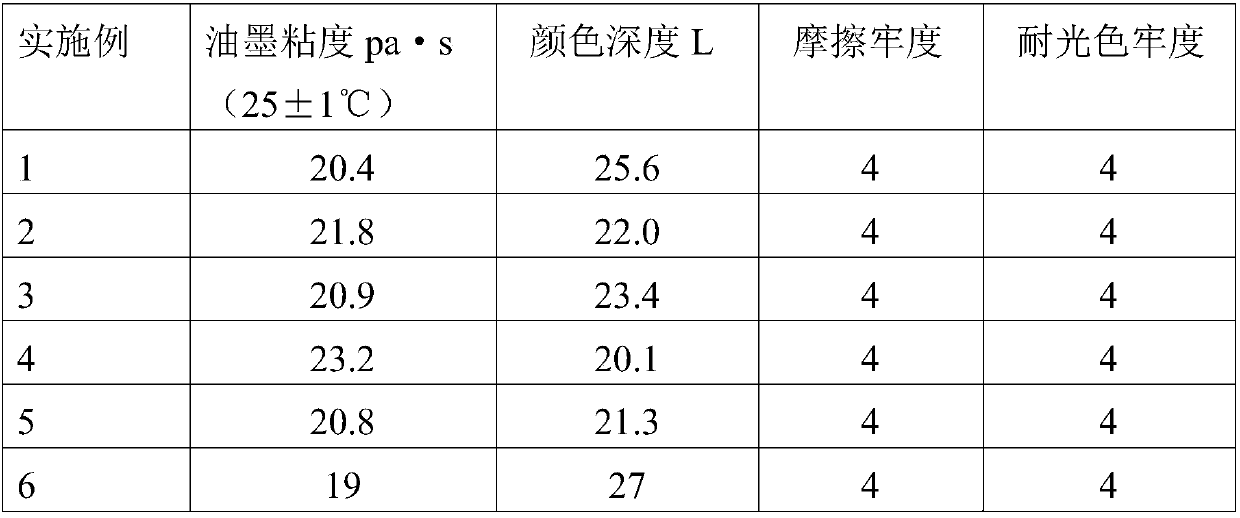

[0027] Measure the viscosity of the color paste at 25°C±1°C with a 2# Zein cup, and scrape the color paste onto the transfer paper with a color scraper, and transfer it under the condition of 200°C and 20s by a pressing machine onto the cloth. Measure the color depth of the color block, measure its color fastness to light with a light fastness meter, and measure its rubbing fastness with a rubbing fastness meter. The test results are shown in Table 1.

Embodiment 2

[0029] Take by weighing 18g brown black disperse ink (4.3g Disperse Yellow 54, 3.8g Disperse Blue359, 9.9g Disperse Brown 27) and 32g original black disperse ink (7.4g Disperse Yellow 54, 9.6g Disperse Blue 359, 4.8g Disperse Orange 25, 10.2g Disperse Violet 13), add 50g of diluent made of clear oil, methanol, isobutanol (1:3:1) and mix to prepare extra black ink color paste, stir evenly with a glass rod.

[0030] Measure the viscosity of the color paste at 25°C±1°C with a 2# Zein cup, and scrape the color paste onto the transfer paper with a color scraper, and transfer it under the condition of 200°C and 20s by a pressing machine onto the cloth. Measure the color depth of the color block, measure its color fastness to light with a light fastness meter, and measure its rubbing fastness with a rubbing fastness meter. The test results are shown in Table 1.

Embodiment 3

[0032] Take by weighing 15g brown black disperse ink (3.6g Disperse Yellow 54, 3.2g Disperse Blue359, 8.2g Disperse Brown 27) and 35g original black disperse ink (8g Disperse Yellow 54, 10.5gDisperse Blue 359, 5.3g Disperse Orange 25, 11.2 g Disperse Violet 13), add 50g diluent made from clear oil, methanol, isobutanol (1:2:2) and mix to prepare extra black ink color paste, stir evenly with a glass rod.

[0033] Measure the viscosity of the color paste at 25°C±1°C with a 2# Zein cup, and scrape the color paste onto the transfer paper with a color scraper, and transfer it under the condition of 200°C and 20s by a pressing machine onto the cloth. Measure the color depth of the color block, measure its color fastness to light with a light fastness meter, and measure its rubbing fastness with a rubbing fastness meter. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com