Low-melt-flow-index EVA composite white photovoltaic adhesive film

A photovoltaic film and melting finger technology, applied in the direction of adhesives, adhesive additives, films/sheets without carriers, etc., can solve the problem of easily overflowing white cells and bus bars, white EVA film wrinkles, affecting the appearance of photovoltaic modules, etc. problems, to achieve the effect of reducing hot melt fluidity, increasing hot melt viscosity, reducing the risk of wrinkles and whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

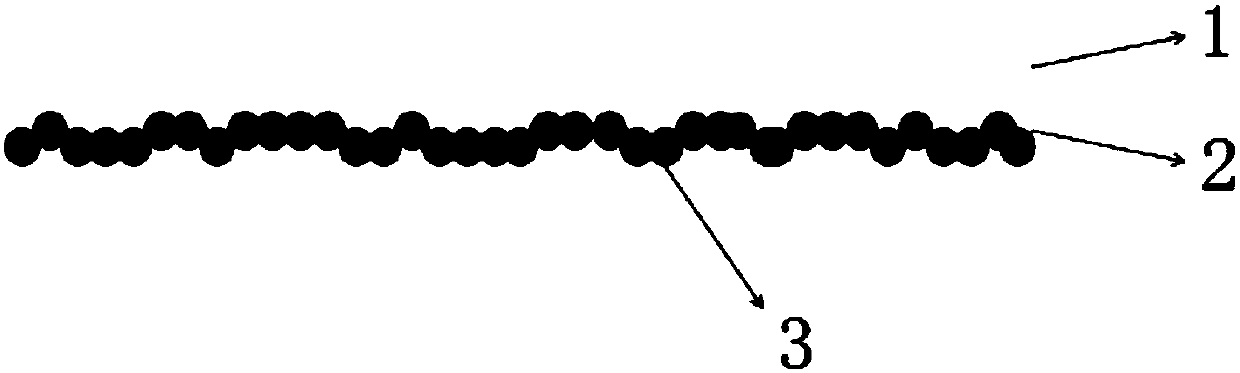

[0020] like figure 1 As shown, the low-melt EVA composite white photovoltaic adhesive film of the present invention includes a lower white EVA layer 1 and an upper transparent EVA layer 2 , and the lower white EVA layer 1 contains white fillers 3 .

[0021] The materials used are:

[0022] Main material: Ethylene-vinyl acetate copolymer (EVA). The VA content is 33%.

[0023] Titanium dioxide: the surface is coated with organic matter, processed into 30-70% concentration of EVA white masterbatch before use.

[0024] Antioxidant: the main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate; the secondary antioxidant is tris(4-nonylphenol) phosphorous acid A complex of esters and tris(2,4-di-tert-butylphenyl)phosphite.

[0025] Cross-linking agent: the cross-linking curing agent is a compound of tert-butyl peroxide 2-ethylhexyl carbonate and 3,3-bis(tert-butyl peroxy) ethyl butyrate; the auxiliary cross-linking agent is triallyl Compounds of isocyanurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com