Method for preparing low-melt-flow-index EVA (Ethylene-Vinyl Acetate) three-layer composite photovoltaic film

A layer compounding and melting finger technology is applied in the field of preparation of low-melting finger EVA three-layer composite white photovoltaic adhesive film, which can solve the problems of low hot-melt fluidity, improve hot-melt viscosity, eliminate air bubbles and hidden cracks, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

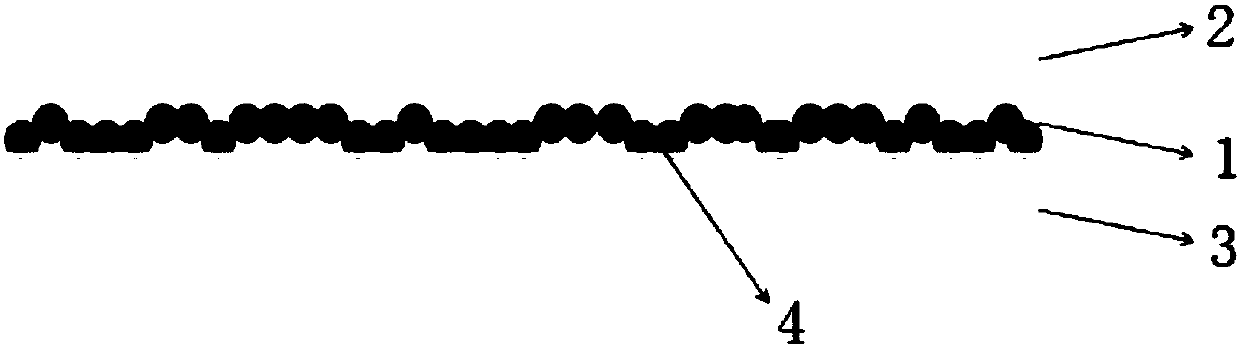

[0019] Such as figure 1 As shown, the low-melt index EVA three-layer composite white photovoltaic film of the present invention includes a middle white EVA layer 1 and an upper transparent EVA layer 2 and a lower transparent EVA layer 3 arranged above and below the middle white EVA layer. In the middle white EVA layer Contains white filler.

[0020] The materials used are:

[0021] Main material: ethylene-vinyl acetate copolymer (EVA). The VA content is 33%, and the melt index is 7.5g / 10min.

[0022] Titanium dioxide: the surface is coated with organic matter and processed into 30-70% concentration EVA white masterbatch for use.

[0023] Antioxidant: the main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate; the auxiliary antioxidant is tris(4-nonylphenol) phosphorous acid A compound of ester and tris(2,4-di-tert-butylphenyl) phosphite.

[0024] Cross-linking agent: cross-linking curing agent is a compound of 2-ethylhexyl tert-butyl peroxide and 3,3-di(tert-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com