Low-melt-flow-index EVA three-layer composite white photovoltaic adhesive film

A photovoltaic film and layer composite technology, applied in the direction of adhesives, adhesive additives, films/sheets without carriers, etc. The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

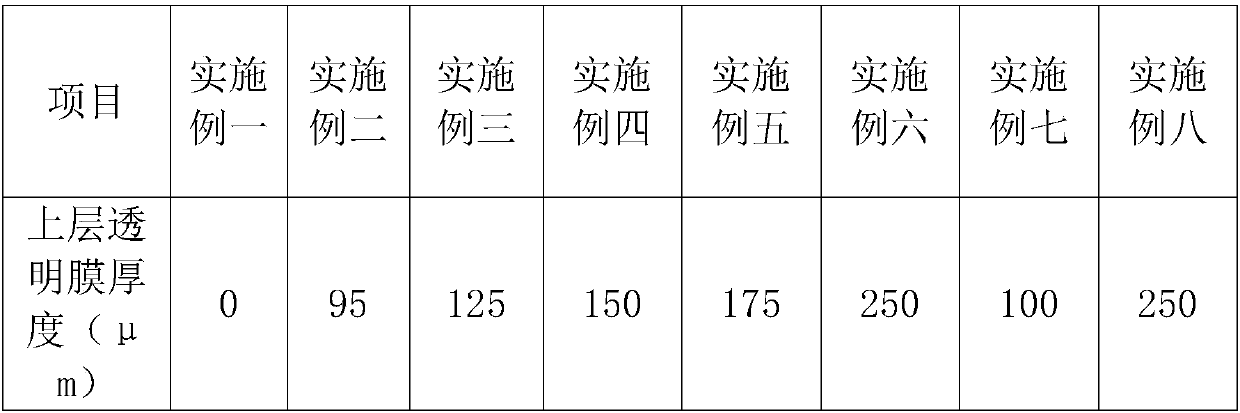

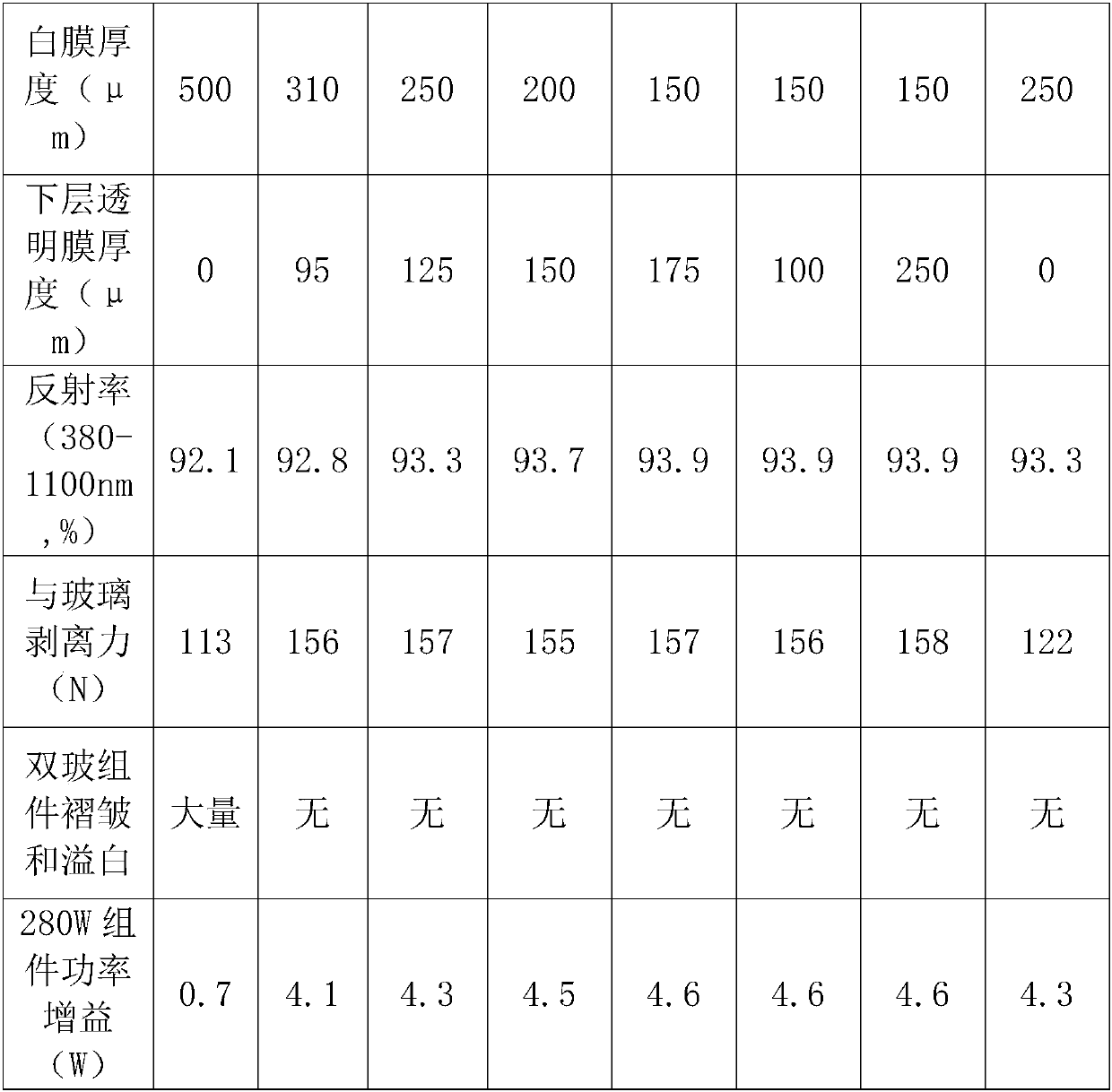

Examples

Embodiment Construction

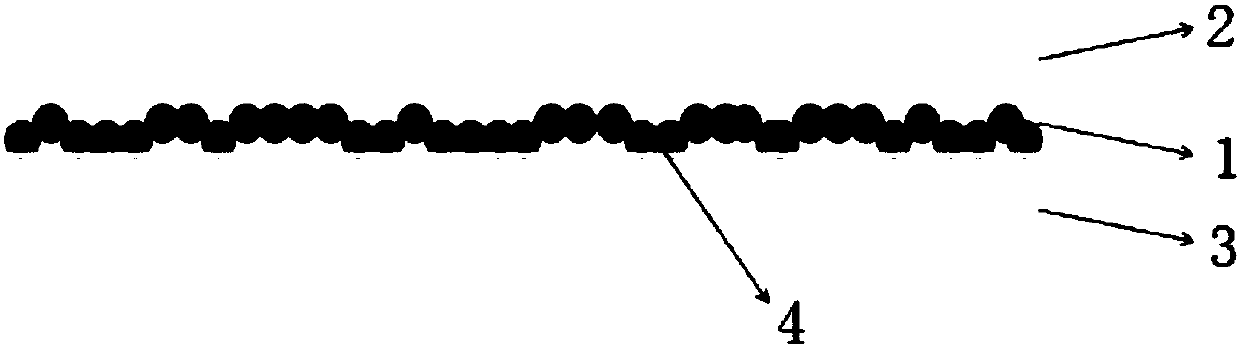

[0021] Such as figure 1 As shown, the low-melt EVA three-layer composite white photovoltaic adhesive film of the present invention includes a middle white EVA layer 1 and an upper transparent EVA layer 2 and a lower transparent EVA layer 3 arranged on the middle white EVA layer. Contains white filler.

[0022] The materials used are:

[0023] Main material: Ethylene-vinyl acetate copolymer (EVA). The VA content is 33%, and the melt index is 7.5g / 10min.

[0024] Titanium dioxide: the surface is coated with organic matter, processed into 30-70% concentration of EVA white masterbatch before use.

[0025] Antioxidant: the main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate; the secondary antioxidant is tris(4-nonylphenol) phosphorous acid A complex of esters and tris(2,4-di-tert-butylphenyl)phosphite.

[0026] Cross-linking agent: the cross-linking curing agent is a compound of tert-butyl peroxide 2-ethylhexyl carbonate and 3,3-bis(tert-butyl peroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com