Coarse metaclazepam dealcoholization transformation system

A technology for methanol and methyl ester, applied in the field of crude methyl ester dealcoholization transformation system, can solve the problems of poor product quality, large investment, high consumption of raw materials, etc., and achieve the effects of improving efficiency, reasonable setting and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below according to the drawings and embodiments.

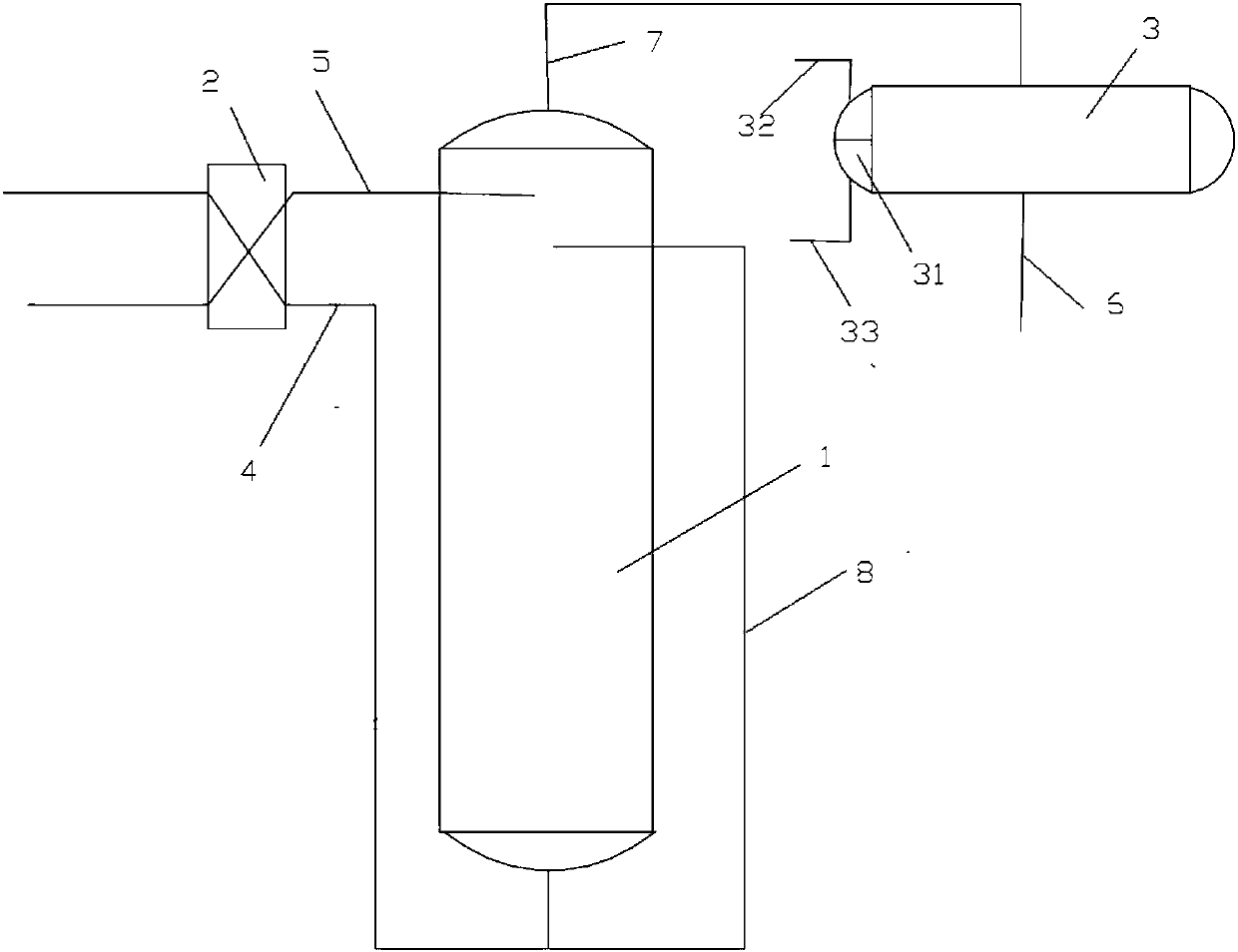

[0012] figure 1 It is the structure frame diagram of crude methyl ester dealcoholization modification system of the present invention, with reference to figure 1 , the present invention, crude methyl ester dealcoholization transformation system, including kettle body 1, heat recovery heat exchange device 2, methanol condenser 3, hot oil cooling pipe 4, cold oil heating pipe 5, methanol input pipe 6, methanol output pipe 7 , Dealcoholization return pipe 8.

[0013] For the heat exchange part of the system, one end of the above-mentioned hot oil cooling pipe 4 is connected to the bottom of the above-mentioned kettle body 1, and the other end is connected to the oil recovery device (not shown in the figure), and one end of the above-mentioned cold oil heating pipe 5 is connected to the above-mentioned kettle body 1 The other end leads to the oil supply device (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com