Preparation method of flaxseed meal polypeptide

A technology of linseed meal and polypeptide liquid, which is applied in the field of preparation of linseed meal polypeptide, can solve the problems of high cost, long process time, destruction of protein or amino acid structure and properties, etc., and achieves short time, good application prospect and high extraction rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

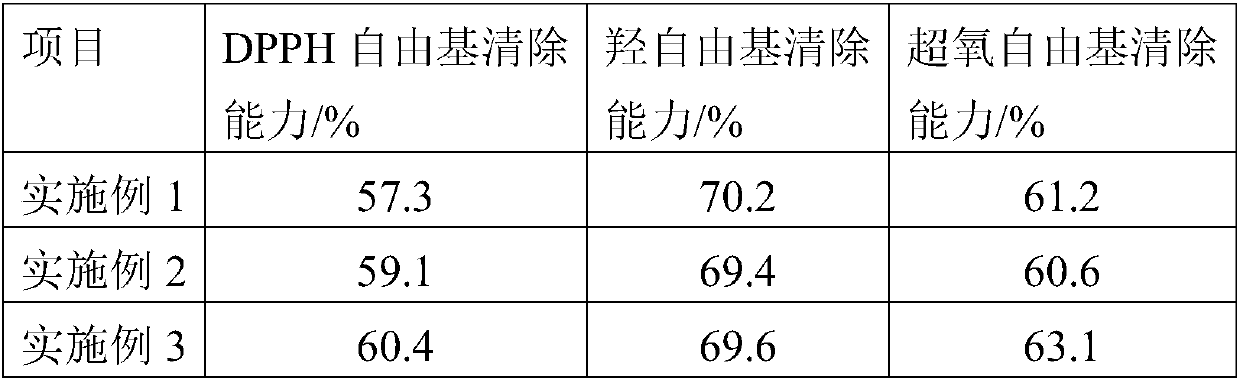

Examples

Embodiment 1

[0034] A preparation method of linseed meal polypeptide, said preparation method comprising the steps of:

[0035] (1) Pulverize the shelled linseed meal with a pulverizer, then cross a 40-mesh sieve to remove impurities to obtain pulverized material;

[0036] (2) Mix the ground linseed meal with the mixed solvent n-hexane-isopropanol-NaOH (the mass ratio of the ground linseed meal to the mixed solvent is 1:6, n-hexane:isopropanol:NaOH=2:7 : 1 (volume ratio), the massfraction of NaOH solution is 5%), utilize ultrasonic (power is 400w) auxiliary leaching 4h, centrifugal (4000r / min, 10min) carries out solid-liquid separation, obtains solid wet meal;

[0037] (3) Put the solid wet meal prepared in step (2) into an oven for drying at a temperature of 55° C. to remove the organic solvent remaining in the sample;

[0038] (4) Add water to the dried linseed meal in step (3), mix and adjust to a mass concentration of 10%, finely pulverize (power 45Hz) and colloid mill to obtain a lin...

Embodiment 2

[0046] (1) Pulverize the shelled linseed meal with a pulverizer, then cross a 50-mesh sieve to remove impurities to obtain pulverized material;

[0047] (2) Mix the ground linseed meal with the mixed solvent n-hexane-isopropanol-NaOH (the mass ratio of the ground linseed meal to the mixed solvent is 1:7, n-hexane:isopropanol:NaOH=3:6 : 1 (volume ratio), the mass fraction of NaOH solution is 7%), utilize ultrasonic (power is 500w) auxiliary leaching 3h, centrifuge (4500r / min, 7min) carry out solid-liquid separation, get solid wet meal;

[0048] (3) Put the solid wet meal prepared in step (2) into an oven to dry at a temperature of 60° C. to remove the organic solvent remaining in the sample;

[0049] (4) Add water to the dried linseed meal in step (3), mix and adjust to a mass concentration of 15%, finely pulverize (power 35Hz), and colloid mill to obtain a mixed liquor of linseed meal;

[0050] (5) Enzymolyze the linseed meal mixture by using a two-step enzymolysis method, ad...

Embodiment 3

[0057] (1) Pulverize the shelled linseed meal with a pulverizer, then cross a 60-mesh sieve to remove impurities to obtain pulverized material;

[0058] (2) Mix the ground linseed meal with the mixed solvent n-hexane-isopropanol-NaOH (the mass ratio of the ground linseed meal to the mixed solvent is 1:8, n-hexane:isopropanol:NaOH=4:5 : 1 (volume ratio), the massfraction of NaOH solution is 10%), utilize ultrasonic (power is 600w) auxiliary leaching 2h, centrifuge (5000r / min, 5min) carry out solid-liquid separation, get solid wet meal;

[0059] (3) Put the solid wet meal prepared in step (2) into an oven to dry at a temperature of 60° C. to remove the organic solvent remaining in the sample;

[0060] (4) Add water to the dried linseed meal in step (3), mix and adjust to a mass concentration of 20%, finely pulverize (power 40Hz) and colloid mill to obtain a mixed liquor of linseed meal;

[0061] (5) Enzymolyze the linseed meal mixture by using two-step enzymolysis method, adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com