Textile label vision automatic cutting machine and its control method

An automatic slitting machine and visual technology, which is applied in the cutting of textiles, papermaking, and textile materials, etc., can solve the problems of inconsistent label width and spacing, low production efficiency of slitting lines, and increased labor costs. The effect of reducing the production of cutting defective products and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

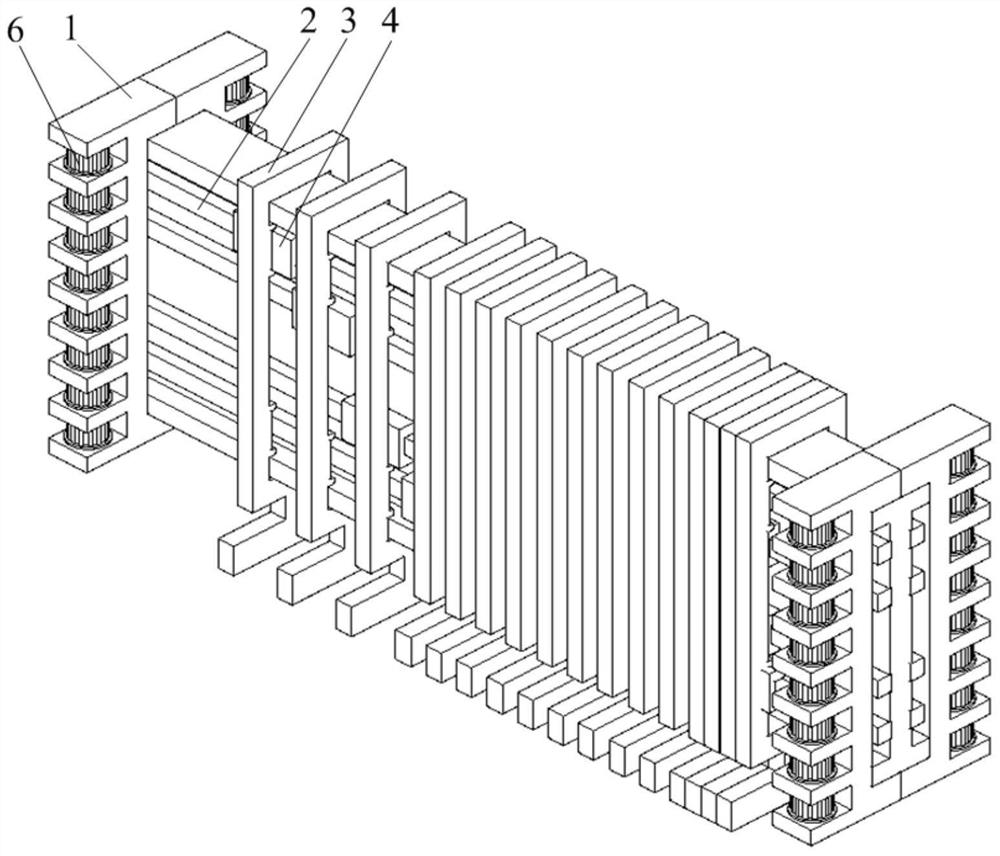

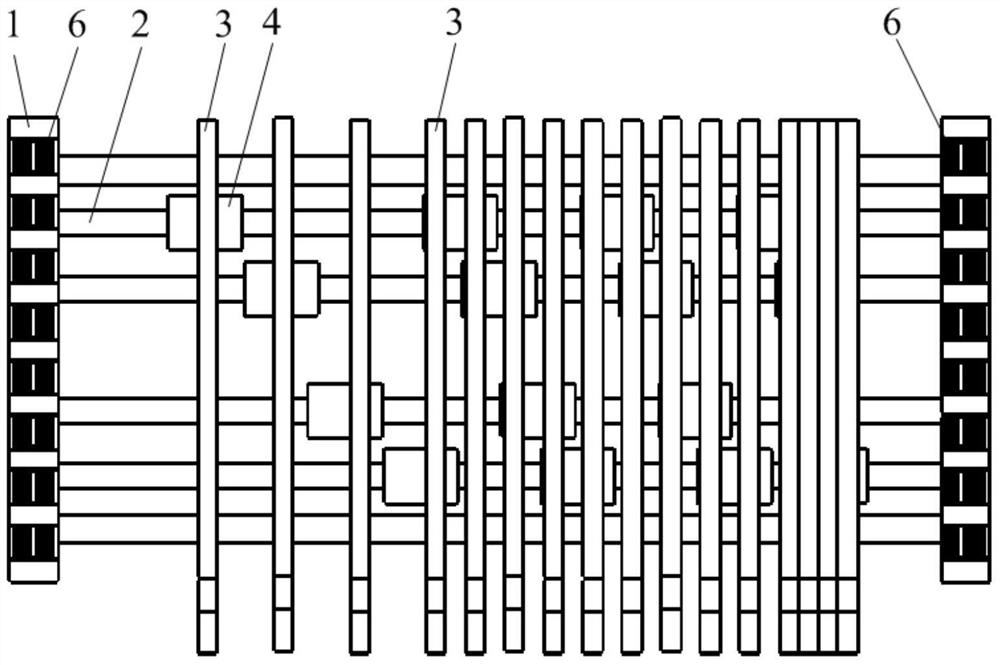

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

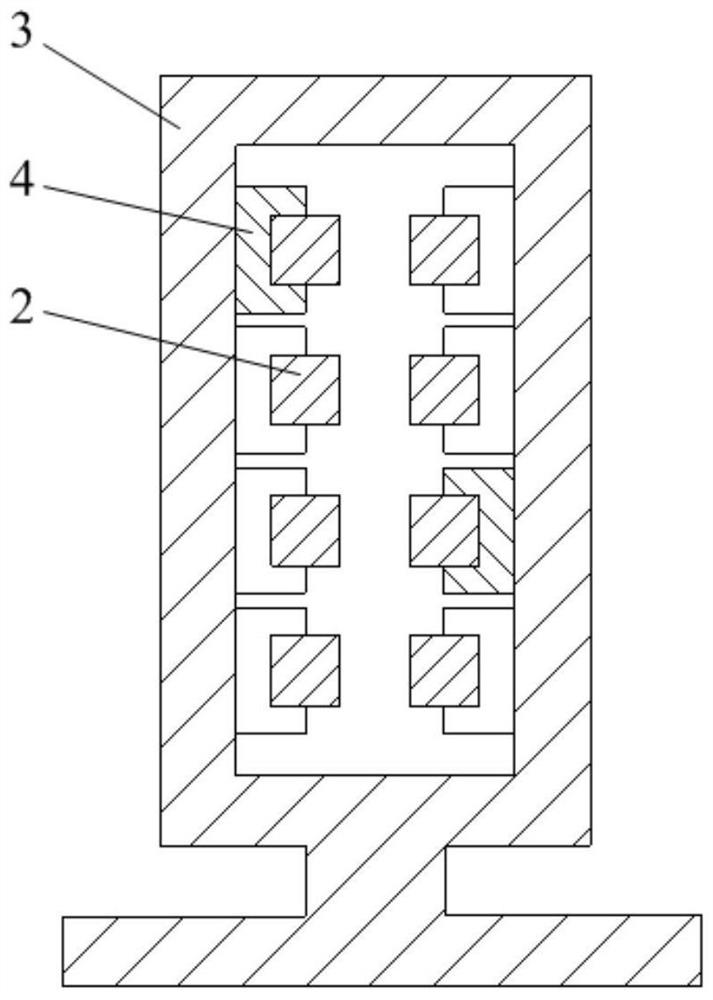

[0028] like figure 1 and Image 6 , the present invention provides a visual automatic slitting machine for textile labels, comprising a frame 1, on which a plurality of parallel guide rails 2 arranged at intervals are vertically arranged, and in this embodiment, the guide rails 2 extend laterally , eight guide rails 2 are vertically arranged in two rows, and each row is vertically arranged in four columns. In other embodiments, the number of knives can be set according to the number of textile labels that need to be cut, and then the corresponding number of guide rails 2 can be set. . A plurality of slide plates 3 arranged in parallel are installed on the guide rail 2, and at least one cutting tool is fixed on each slide plate 3. In this embodiment, the cutting tool is an ultrasonic cutting tool. In other embodiments, it can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com