Boiler smoke discharging condensed water heat-carrying circulation based three incorporated tower heat exchange method and device

A condensed water and heat method technology, applied in heating methods, household heating, heating systems, etc., can solve problems such as complex system processes, increased power consumption, and difficult recycling of heat resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

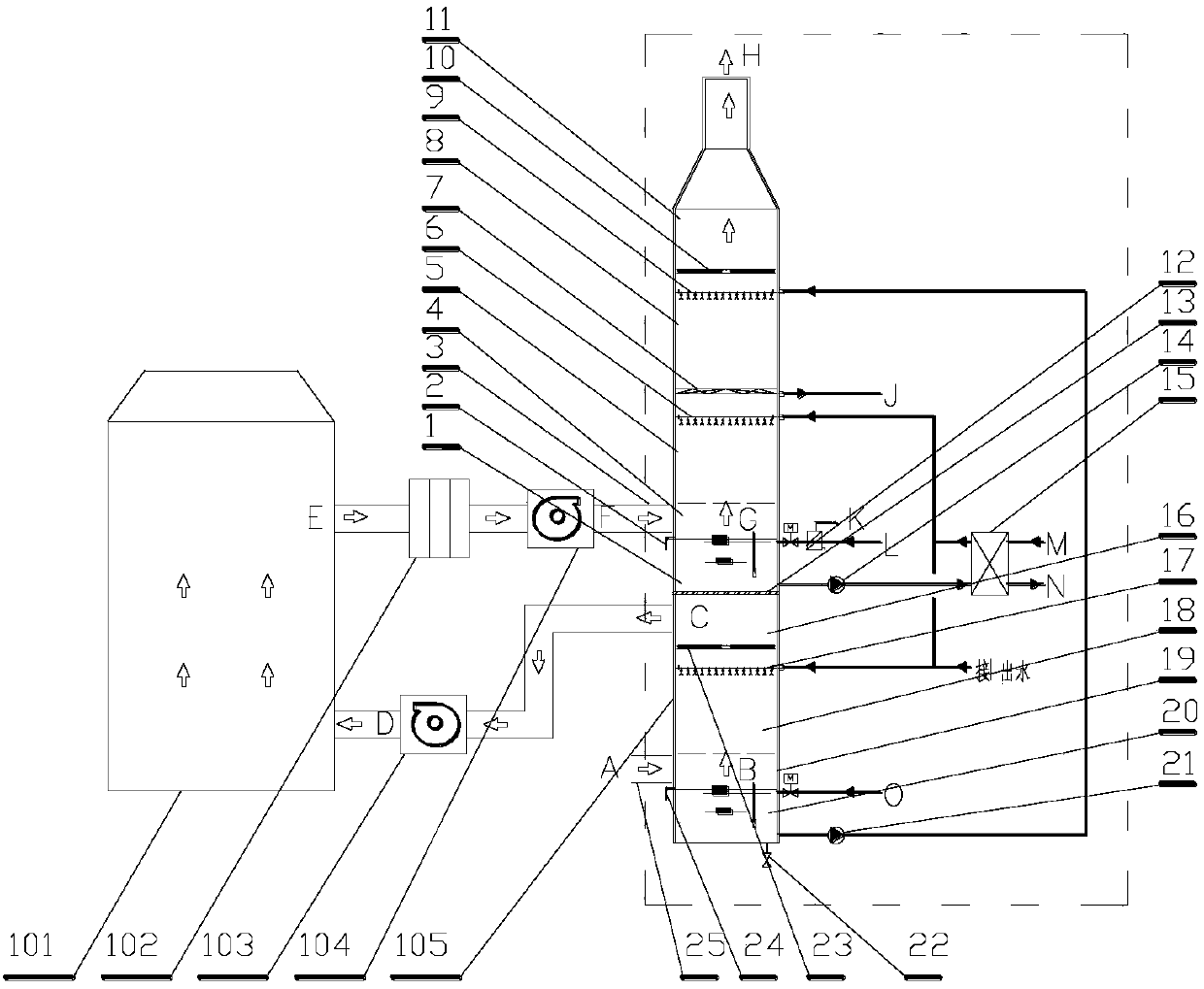

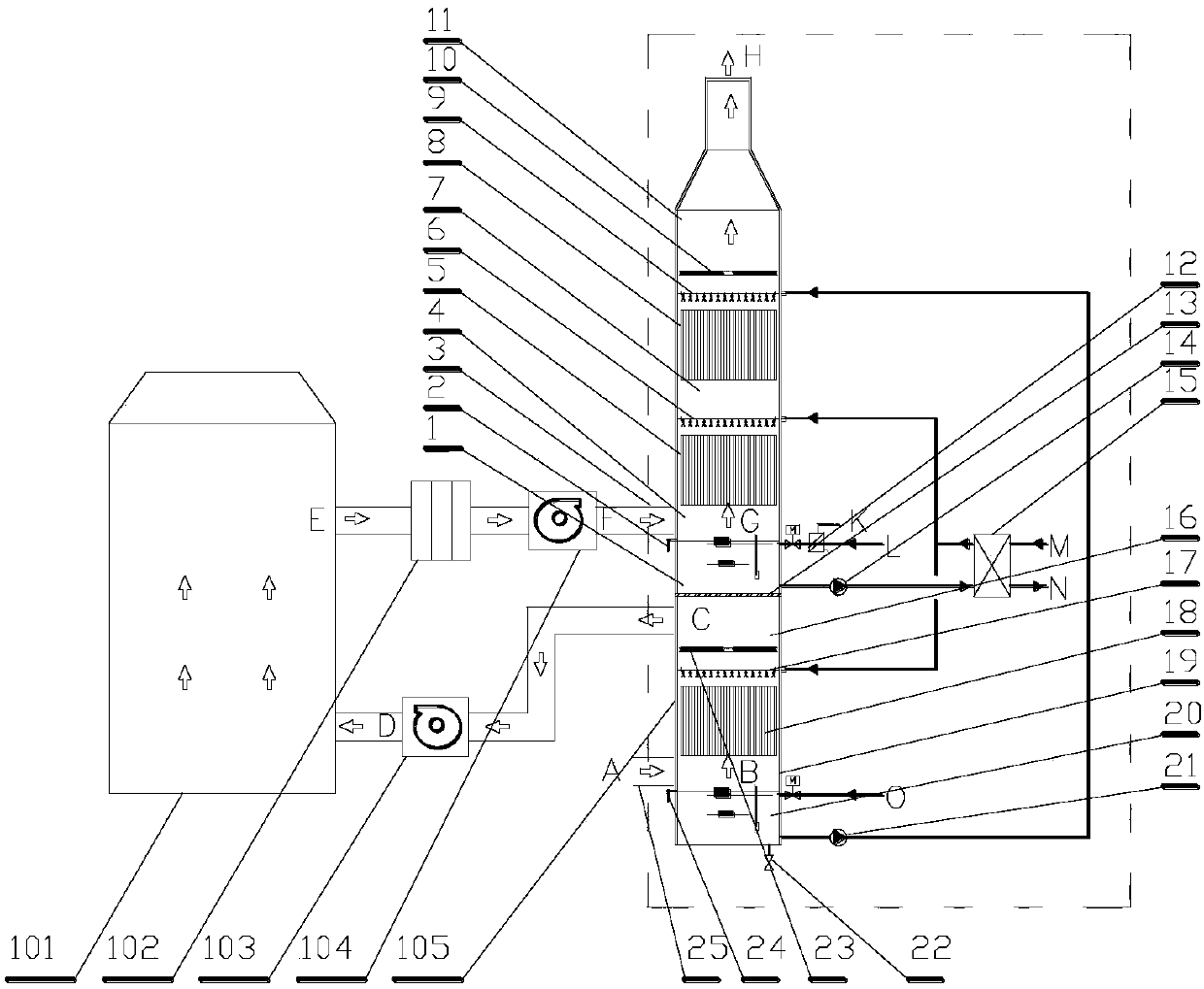

[0020] The specific embodiment 1 of the present invention is as follows.

[0021] The three-tower-in-one heat transfer method and device based on the heat transfer cycle of boiler exhaust condensate water adopts an integrated three-stage spray tower heat transfer structure, and the main equipment in the system process consists of a boiler 101 and an ultra-low emission treatment device 102 , a blower 103, an induced draft fan 104 and a three-stage heat exchange spray tower 105. The three-stage heat exchange spray tower 105 adopts a three-tower heat exchange structure, and from bottom to top are air heating and humidification areas, The flue gas high-temperature heat exchange area and the flue gas low-temperature heat exchange area, in which the air heating and humidification area and the flue gas high-temperature heat exchange area are completely separated by the bottom plate 13 of the flue gas tower bottom pool, and the high-humidity flue gas F enters the flue gas pipe from the...

specific Embodiment 2

[0028] The specific embodiment 2 of the present invention is as follows: the water-air diversion device 7 is not provided in the spray tower of this embodiment, that is, the part forms an empty section structure, and no water-air diversion device communicating with the low-temperature residual hot water outlet J is no longer provided at this time. The water outlet pipe of device 7, the low-temperature residual hot water that falls to the structure of the empty section continues to descend and enters the high-temperature heat exchange section 5 after passing through the spray device 6 of the high-temperature section. The high-temperature heat exchange section 5 , the low-temperature heat exchange section 8 and the air heating and humidifying section 18 are respectively provided with fillers. Except above-mentioned difference, all the other parts are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com