Graphite boat saturation double-layer film structure, coating process and graphite boat

A graphite boat and double-layer film technology, applied in the field of solar cells, can solve the problems of increased boat replacement cost, poor coating uniformity, boat loss, etc., achieve long-term coating uniformity, reduce saturation process time, and prevent Effect of graphite boat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

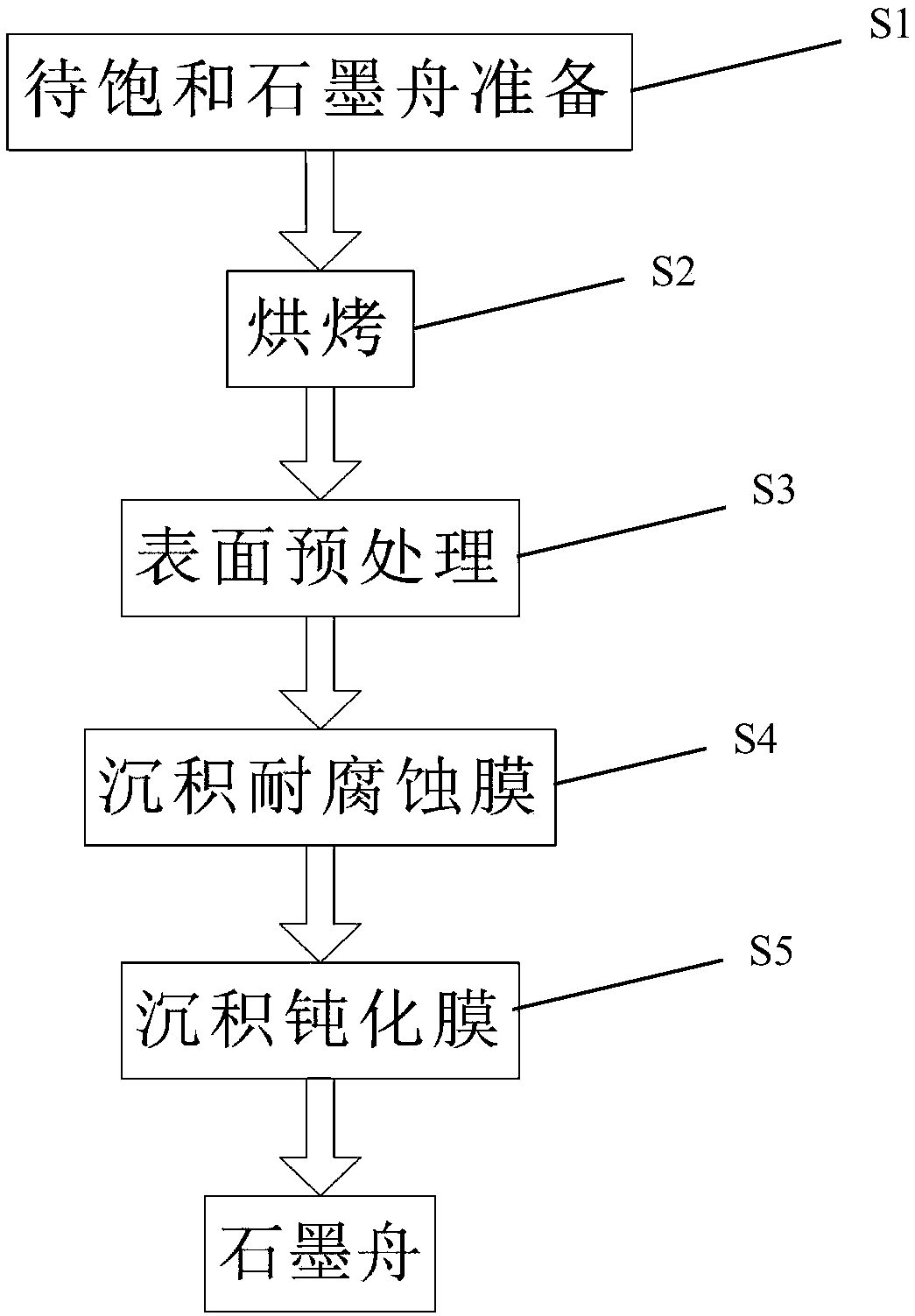

[0028] refer to Figures 1 to 2 , a graphite boat saturated coating in this embodiment has a double-layer film structure, including a corrosion-resistant film deposited on the graphite boat and a passivation film deposited on the corrosion-resistant film. The corrosion-resistant film in this embodiment is a SiC film, and the passivation film is a SixNy film.

[0029] The present embodiment also provides a graphite boat saturated double-layer coating process, comprising the following steps:

[0030] Step S1: Prepare the graphite boat to be saturated

[0031] Put the graphite boat into 25% HF solution for cleaning, remove the SixNy layer, dry and assemble after cleaning.

[0032] Step S2: Baking

[0033] Send the cleaned graphite boat to the tubular PECVD furnace tube to start the saturation process, vacuumize the tubular PECVD and raise the temperature to 450°C. When the temperature reaches 450°C, N 2 , the flow rate is 10slm, and the graphite boat is baked for 20 minutes....

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, except that the specific process parameters for depositing the SiC film in this embodiment are: deposition temperature 350°C, CH 4 Flow rate is 600sccm, SiH 4 The flow rate is 800sccm, the pressure is 1700mTorr, the deposition power is 7000W, the deposition ends when the deposition time reaches 90min, and the SiC film thickness is 0.5um.

[0042] The specific process parameters for depositing SixNy film are: deposition temperature is 350°C, NH3 Flow rate of 7slm, SiH 4 The flow rate is 1000sccm, the pressure is 2200mTorr, the deposition power is 9000W, the deposition ends when the deposition time reaches 8min, and the thickness of the SixNy film is 100nm.

Embodiment 3

[0044] refer to Figure 3 to Figure 4 , a graphite boat saturated coating in this embodiment has a double-layer film structure, including a corrosion-resistant film deposited on the graphite boat and a passivation film deposited on the corrosion-resistant film. The corrosion-resistant film of this embodiment is Al 2 o 3 film, the passivation film is SixNy film.

[0045] The present embodiment also provides a graphite boat double-layer coating process, comprising the following steps:

[0046] Step S1: Prepare the graphite boat to be saturated

[0047] Put the graphite boat into 25% HF solution for cleaning, remove the SixNy layer, dry and assemble after cleaning.

[0048] Step S2: Baking

[0049] Send the cleaned graphite boat to the tubular PECVD furnace tube to start the saturation process, vacuumize the tubular PECVD and raise the temperature to 400°C. When the temperature reaches 400°C, N 2 , the flow rate is 10slm, and the graphite boat is baked for 20 minutes.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com