Rice seedling raising method

A technology for raising rice seedlings and rice seeds, applied in the field of rice seedling raising, can solve the problems of reducing fertilizer utilization rate, uneven fertilization, and low efficiency, and achieve the effect of improving fertilizer utilization efficiency and solving uneven artificial fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

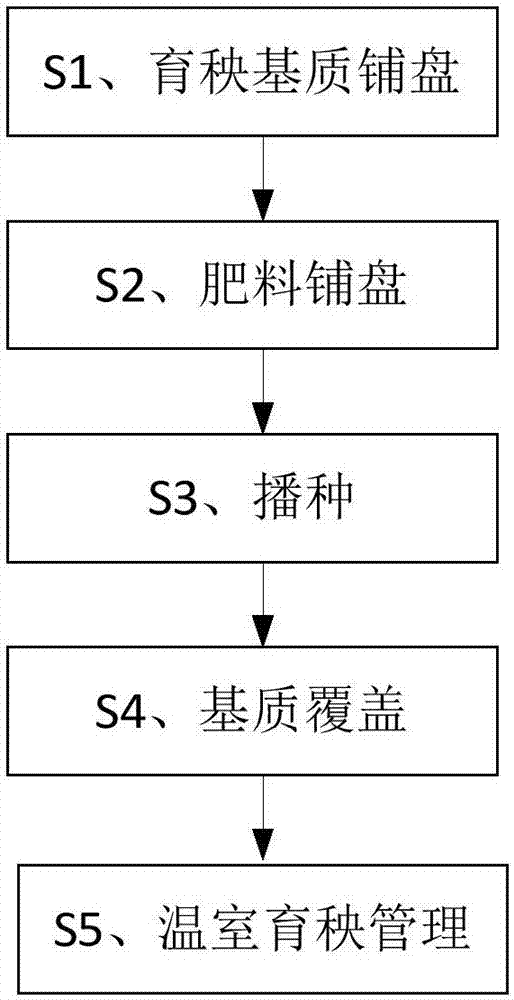

[0033] figure 1 Show the step flowchart of rice seedling raising method of the present invention, it comprises the steps:

[0034] S1, seedling-raising substrate laying tray: prepare a seedling tray, and lay the substrate in the seedling tray; wherein, the seedling tray is a cuboid structure, its length is 55-60cm (preferably 57.5cm), and its width is 25-30cm ( is preferably 27.5cm), and the thickness of the matrix laid in the seedling tray is 1.8-2.0cm;

[0035] S2, fertilizer laying tray: spread fertilizer on the substrate in the seedling tray; preferably, the fertilizer is coated slow / controlled release urea, and the fertilizer application rate is 350-400 grams of pure nitrogen / every seedling tray (preferably is 380 grams / per seedling tray), and the fertilizers have a longer release period to correspond to the "S" type release characteristic curve, which can basically match the nutrient requirements of crops, and have the advantages of "efficiency enhancement, fertilizer s...

Embodiment 2

[0051] The difference between this example and Example 1 is that in step S2, the film is coated with slow / controlled release of urea, and the fertilizer application rate is 350 grams of pure nitrogen per seedling tray; and the fertilizers all have a longer release period To correspond to the "S" type release characteristic curve, it can basically match the nutrient requirements of crops, and has the advantages of "efficiency increase, fertilizer saving, labor saving, environmental protection" and so on;

[0052] On this basis, in steps S1 and S4, the matrix includes: 50% of crop straw powder, 19% of mushroom chaff, 9% of peat, 7% of water retaining agent, 6% of binder and accelerator Root dose 0.3%, and the rest are auxiliary materials.

[0053] The seedlings were raised in about 20 days and transplanted. During the seedling raising process, there was no phenomenon of fertilizer damage to the seedlings. After that, the conventional rice planting operations were followed, and p...

Embodiment 3

[0055] The difference between this example and Example 1 is that in step S2, the coating slows down / controlled release of urea, and the fertilizer application rate is 400 grams of pure nitrogen per seedling tray; and the fertilizers all have a longer release period To correspond to the "S" type release characteristic curve, it can basically match the nutrient requirements of crops, and has the advantages of "efficiency increase, fertilizer saving, labor saving, environmental protection" and so on;

[0056] On this basis, in steps S1 and S4, the matrix includes: 60% of crop straw powder, 16% of mushroom chaff, 8% of peat, 5% of water retaining agent, 5% of binder and accelerator Root dose 0.2%, and the rest are auxiliary materials.

[0057] The seedlings were grown in about 20 days and transplanted. During the seedling raising process, there was no phenomenon of fertilizer damage to the seedlings. After that, the conventional rice planting operations were followed, and phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com