Preparation method and application of porous single-layer MoS1.85 nanonet

A technology of mos1.85 and nanonet, applied in the direction of catalyst activation/preparation, chemical instruments and methods, electrode shape/type, etc., can solve the problems that are not suitable for large-scale synthesis and require high temperature, so as to facilitate transmission and transfer, The effect of speeding up the speed and the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

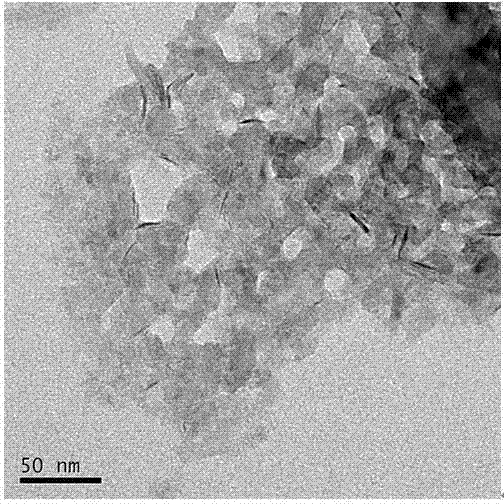

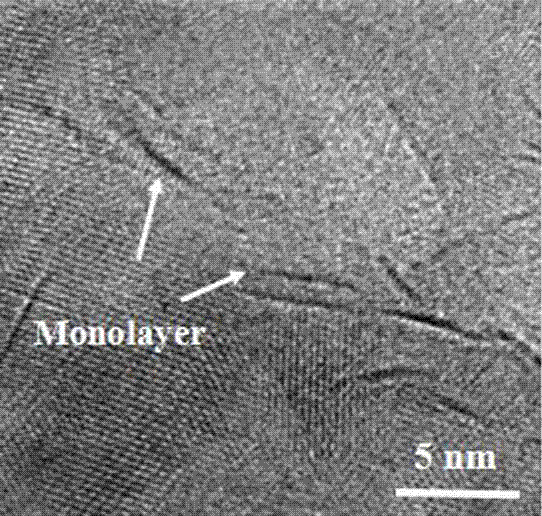

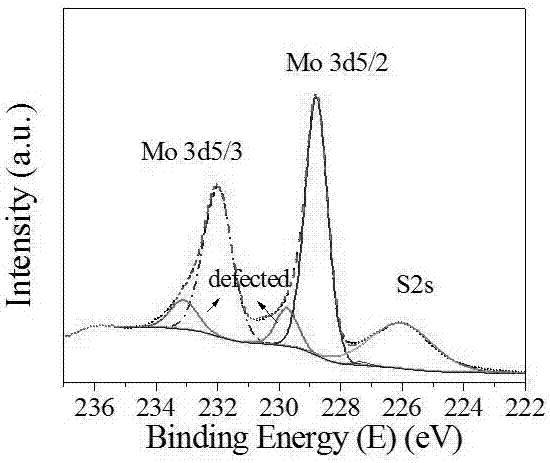

[0029] The porous monolayer MoS of this example 1.85 The preparation method of nanonet, the steps are as follows:

[0030] (1) Preparation of MoS by hydrothermal method 2 Nanosheets;

[0031] 1) Mix 67.5 mg sodium molybdate and 135.0 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 30 mL deionized water to obtain mixture A;

[0032] 2) Stir mixture A into a transparent solution, put it in a 40 mL hydrothermal reaction kettle, heat it at 220°C for 10 hours, and obtain sample B after precipitation and filtration;

[0033] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 60 °C for 12 hours to obtain multilayer MoS 2 Nanosheets;

[0034] (2) Treating MoS by grinding ball method 2 Nanosheets: take 5 g MoS 2 Nanosheets and 100 g of 10 mm stainless steel balls were put into a ball mill, and the balls were milled for 26 hours at a speed of 300 rpm in an argon atmosphere;

[0035] (3) Preparation of MoS by ultrasonic method in aqueous solution ...

Embodiment 2

[0039] The porous, monolayer MoS of this example 1.85 The preparation method of nanonet, the steps are as follows:

[0040] (1) Preparation of MoS by hydrothermal method 2 Nanosheets:

[0041] 1) Mix 45.0 mg sodium molybdate and 90.0 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 20 mL deionized water to obtain mixture A;

[0042] 2) Stir the mixture A into a transparent solution, put it in a 40 mL hydrothermal reaction kettle, heat it at 180°C for 26 hours, and obtain sample B after precipitation and filtration;

[0043] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 80 °C for 12 hours to obtain multilayer MoS 2 Nanosheets;

[0044] (2) Treating MoS by grinding ball method 2 Nanosheets: take 5 g MoS 2 Nanosheets and 125 g of 10 mm stainless steel balls were put into a ball mill, and the balls were milled at a speed of 400 rpm for 24 hours in an argon atmosphere;

[0045] (3) Preparation of MoS by ultrasonic method in aqueous soluti...

Embodiment 3

[0048] The porous, monolayer MoS of this example 1.85 The preparation method of nanonet, the steps are as follows:

[0049] (1) Preparation of MoS by hydrothermal method 2 Nanosheets:

[0050] 1) Mix 56.3 mg sodium molybdate and 112.5 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 25 mL deionized water to obtain mixture A;

[0051] 2) Stir the mixture A into a transparent solution, put it in a 40 mL hydrothermal reaction kettle, heat it at 200°C for 20 hours, and obtain sample B after precipitation and filtration;

[0052] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 70 °C for 12 hours to obtain multilayer MoS 2 Nanosheets;

[0053] (2) Treating MoS by grinding ball method 2 Nanosheets: take 5 g MoS 2 Nanosheets and 150 g of 10 mm stainless steel balls were put into a ball mill, and the balls were milled at a speed of 500 rpm for 22 hours in an argon atmosphere;

[0054] (3) Preparation of MoS by ultrasonic method in aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com