Hydroxyl polyester resin for polypropylene primer, and preparation method and application of hydroxyl polyester resin

A hydroxyl polyester resin, polypropylene technology, applied in the field of polyester resin, can solve the problems of poor water resistance, chemical resistance and heat and humidity resistance of PP primer, and achieve low price, easy availability and excellent water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

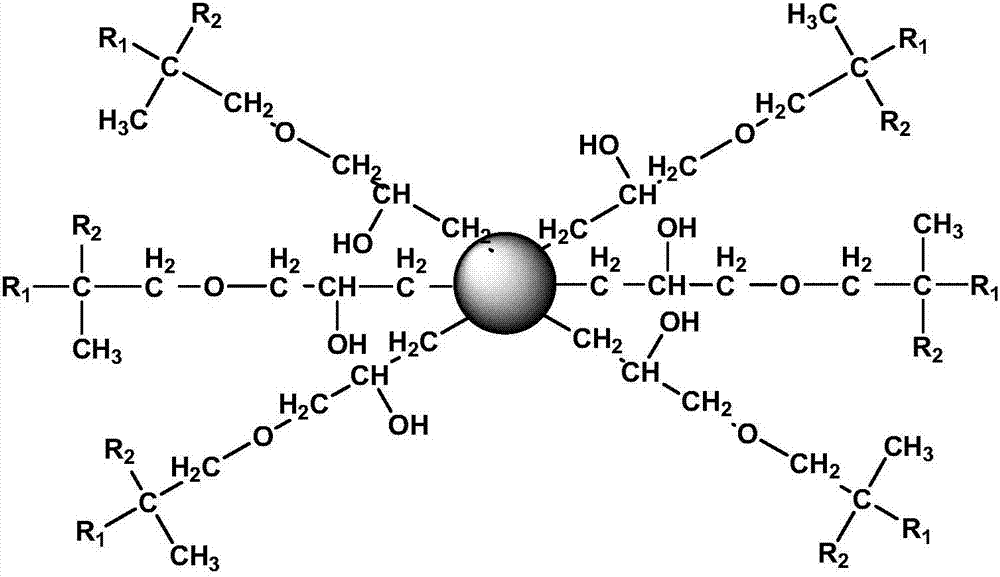

Method used

Image

Examples

Embodiment Construction

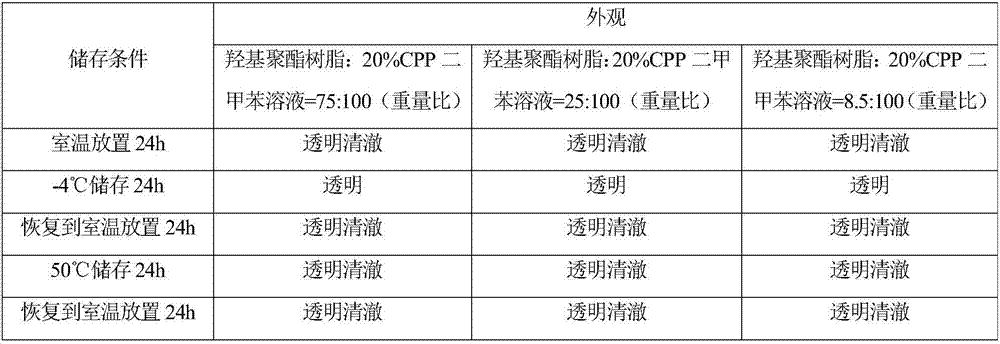

[0045] In order to better understand the present invention, the present invention will be further described below through examples, which are only used to explain the present invention and do not constitute any limitation to the present invention.

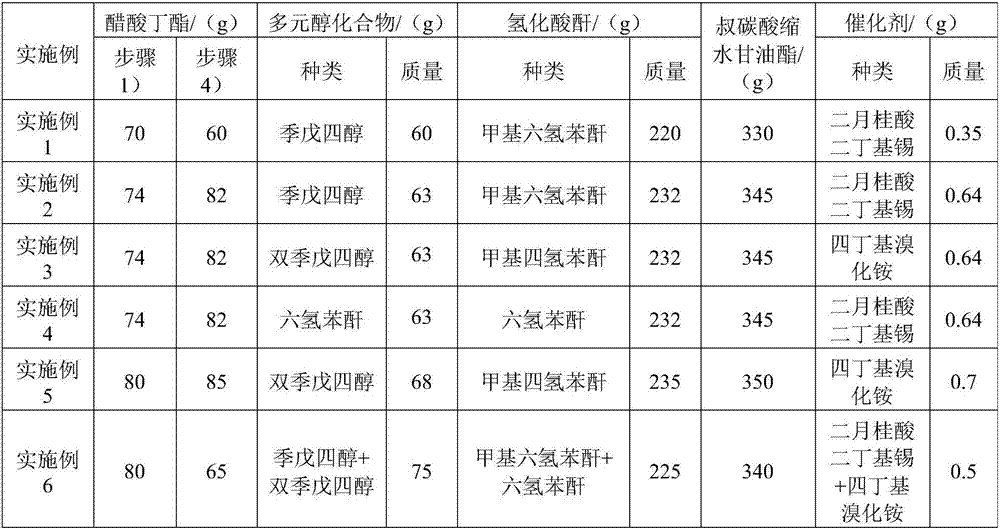

[0046] Table 1 shows the proportions of the components of the hydroxyl polyester resin used in the polypropylene primers of Examples 1 to 6 of the present invention.

[0047] Table 1

[0048]

[0049] The method for the polypropylene primer of preparation embodiment 1~embodiment 6 uses hydroxyl polyester resin, comprises the following steps:

[0050] 1) butyl acetate, polyol compound, and hydrogenated anhydride are dropped into the reactor in sequence;

[0051] 2) Turn on the stirrer of the reactor, and continuously feed in N 2 , and slowly raise the temperature to 100-130°C to stop heating, and reheat to 140-160°C when the exothermic reaction makes the temperature of the material no longer rise, and then keep warm until the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com