A high-efficiency and environment-friendly uv-dark curing three-proof paint

A three-proof paint, UV-technology, used in anti-corrosion coatings, fire-resistant coatings, coatings and other directions, can solve the problems of the decline of the insulation performance and anti-corrosion performance of the paint film, reduce the service life, increase the difficulty of construction, etc., and achieve the volume shrinkage of the paint film. Small rate, improved efficiency, good curing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] As an embodiment of the present invention, the photoinitiator is 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0065] Leveling aid: Leveling aid is a commonly used coating additive, which can promote the formation of a flat, smooth and uniform coating film during the drying and film-forming process of the coating. A class of substances that can effectively reduce the surface tension of coating fluids and improve their leveling and uniformity. It can improve the permeability of the coating solution, reduce the possibility of spots and marks when brushing, increase the coverage, and make the film formation uniform and natural. Mainly surfactants, organic solvents, etc. There are many types of leveling agents, and the types of leveling agents used in different coatings are also different.

[0066] The leveling aid in the present invention is selected from silicone-based leveling aids.

[0067] The preparation method of silicone-based leveling aid described in the present i...

Embodiment approach 1

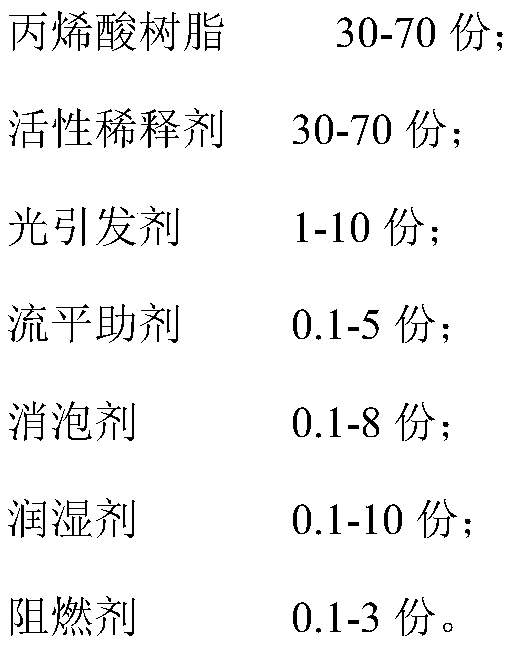

[0087] Embodiment 1: This embodiment provides a highly efficient and environmentally friendly UV-dark curing three-proof paint. According to parts by weight, the preparation raw materials of the three-proof paint include:

[0088]

Embodiment approach 2

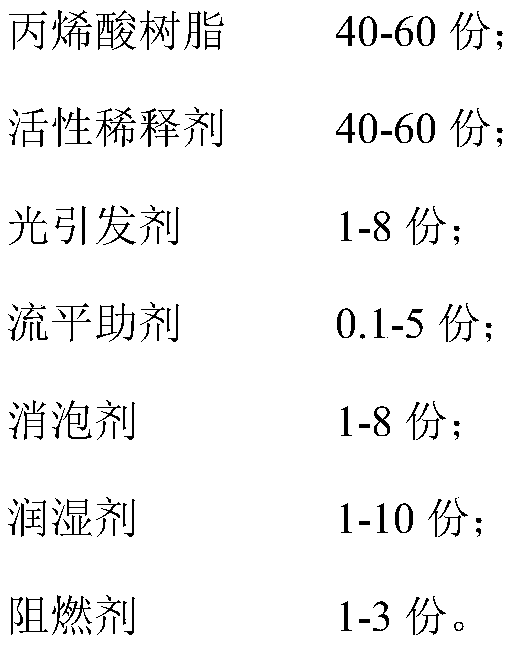

[0089] Embodiment 2. The high-efficiency and environment-friendly UV-dark curing three anti-paints described in embodiment 1, according to parts by weight, the preparation raw materials of the three anti-paints include:

[0090]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com