Silicon nitride film etching solution

A technology for etching solution and silicon nitride film, which is applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problems of declining productivity, changing the etching speed of silicon oxide film, changing the etching speed of silicon nitride film, etc., to achieve Prevents growth and precipitation, suppresses the generation of silicon-based particles, and improves the selectivity ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

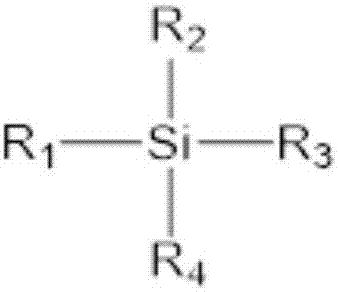

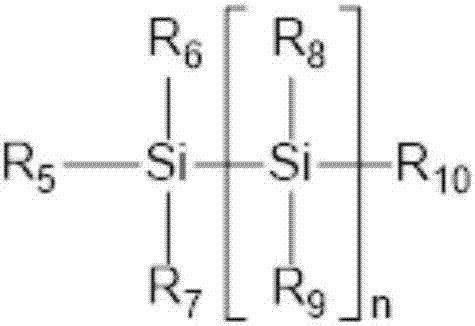

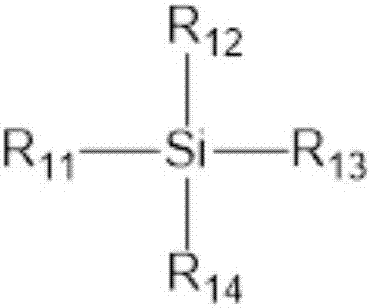

Method used

Image

Examples

Embodiment

[0119] In Table 1 below, the compositions of the silicon nitride film etching solutions of Examples are shown.

[0120] Table 1

[0121]

[0122] The silicon nitride film etching solutions according to Examples 1 to 8 contained 85% by weight of phosphoric acid and the remainder of water, and the first silane compound, the second silane compound, and the fluorine-containing compound described in Table 1 were contained in ppm units.

[0123] In Example 1, tetrahydroxysilane was used as the first silane compound, trimethylhydroxysilane was used as the second silane compound, and hydrofluoric acid was used as the fluorine-containing compound.

[0124] In Example 2, tetrahydroxysilane was used as the first silane compound, trimethylhydroxysilane was used as the second silane compound, and ammonium hydrogen fluoride was used as the fluorine-containing compound.

[0125] In Example 3, tetrahydroxysilane was used as the first silane compound, chlorotrimethylsilane was used as the ...

experiment example 2

[0178] Experimental Example 2: Cleaning solution after etching

[0179] Experimental result 1

[0180] Before putting the silicon substrate including the silicon nitride film into the etching solution, the planarization operation was performed by immersing 50% by weight of hydrofluoric acid in a planarization solution diluted at 200:1 for 30 seconds.

[0181] Then, the planarized silicon substrate was coated with 500ppm tetrahydroxysilane and 500ppm ammonium fluoride (NH 4 F) After etching with 80% phosphoric acid aqueous solution for 5 minutes, wash once for 10 seconds with 80° C. cleaning solution having the composition of each example and comparative example, and then perform 30 seconds with 80° C. deionized water. Second cleaning of the clock.

[0182] The cleaning solution after the first cleaning and the deionized water after the second cleaning are respectively extracted, so that the average diameters of the silicon-based particles in the cleaning solution and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com