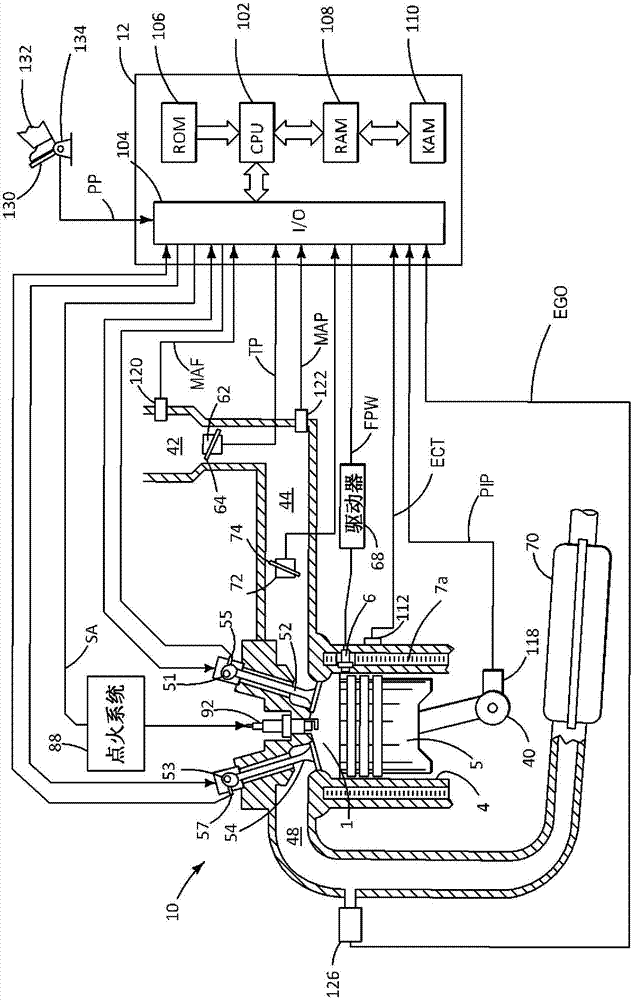

Internal combustion engine having spraying device in cylinder tube, and operating method thereof

A technology for internal combustion engines and injection devices, which is applied in the direction of combustion engines, fuel injection devices, engine components, etc., and can solve the problems that are not suitable for being arranged in the area of the cylinder bore in a concave manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

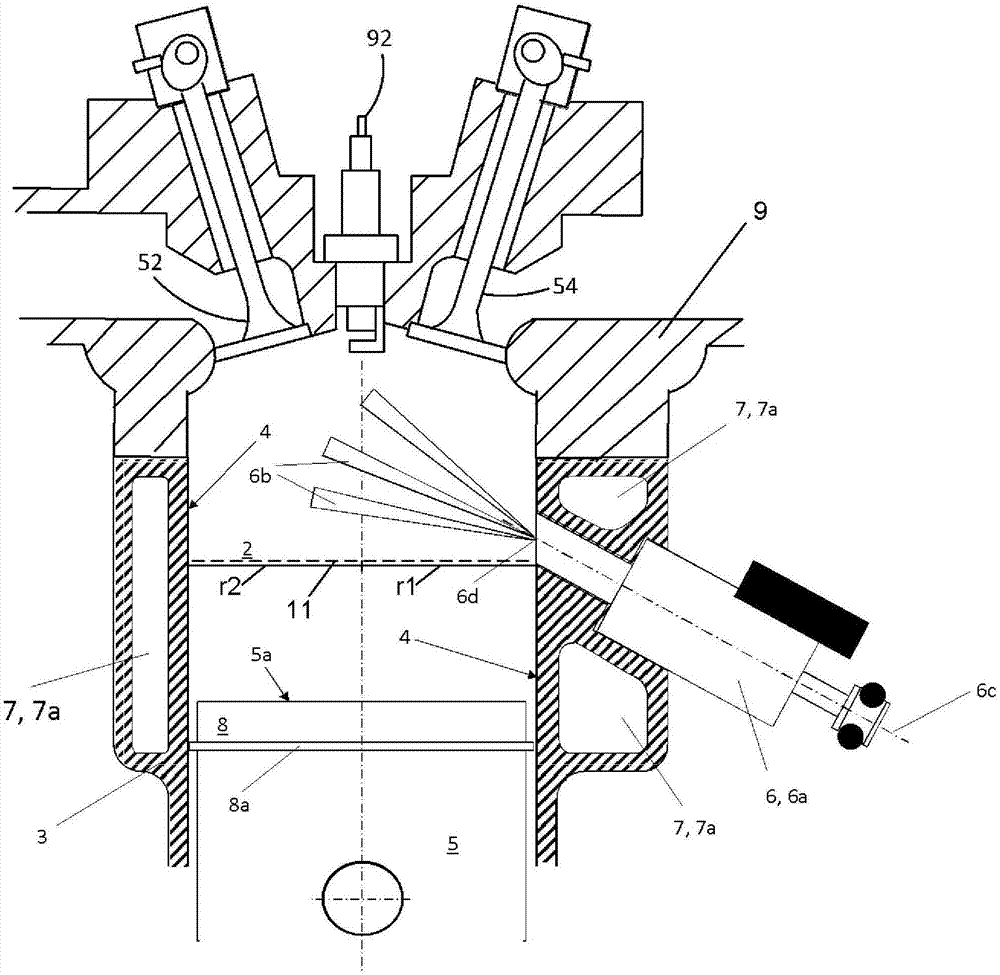

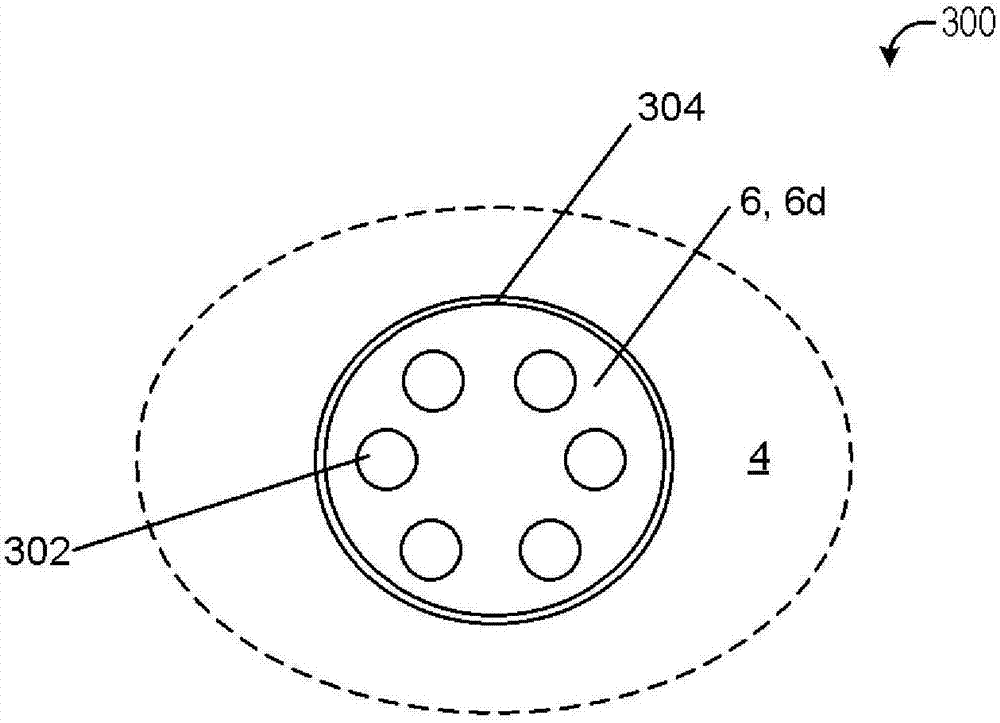

[0044] Mixture preparation in direct injection engines presents challenges because of the negative effects caused by any wall wetting. If the fuel spray hits the cylinder liner, the oil is potentially diluted (eg, the fuel can collect and then drain to an oil pan where the oil can be diluted). Excessive soot formation can occur if the fuel spray strikes the piston. One difficulty with centrally mounted fuel injectors in the cylinder head is the alignment of the flow directions of the fuel and air. The lack of relative motion between the two fuel and air causes a long duration of evaporation, a high penetration length of the spray and thus a high probability of wall wetting.

[0045] Injectors on the side of the cylinder head, so-called side-mounted direct injectors, do not take full advantage of side injection due to the injector's proximity to the intake valve and have limited freedom in positioning due to retraction in the cylinder head .

[0046] According to the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com