Gasification system and its use

A gasification system and gasification reactor technology, applied in the field of gasification systems, can solve problems such as easy damage, and achieve the effects of easy handling and avoiding heat exchange surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

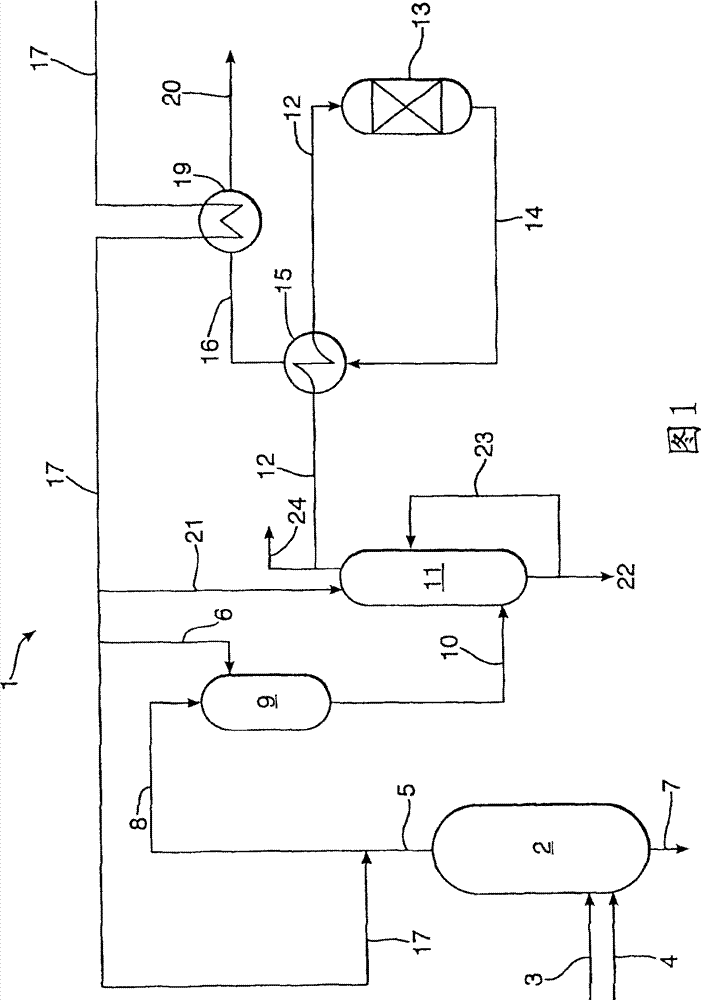

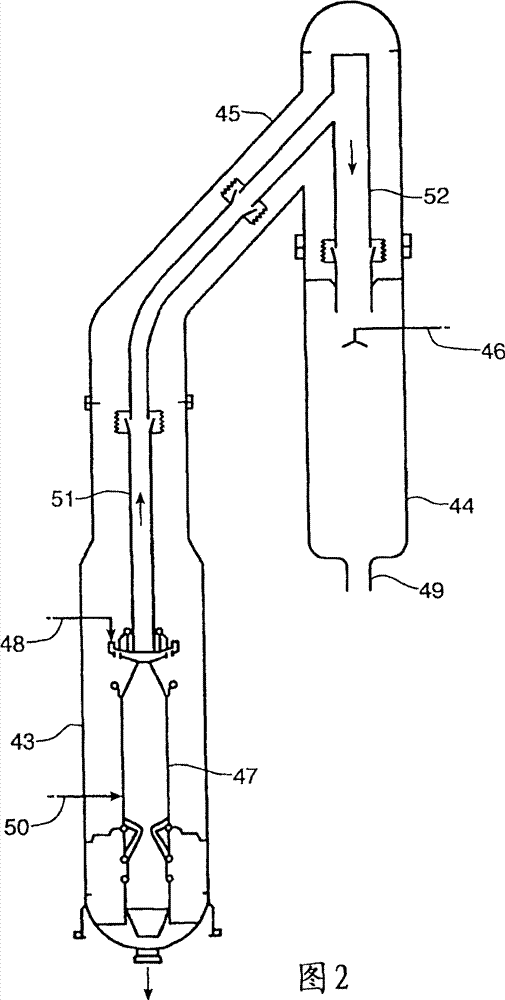

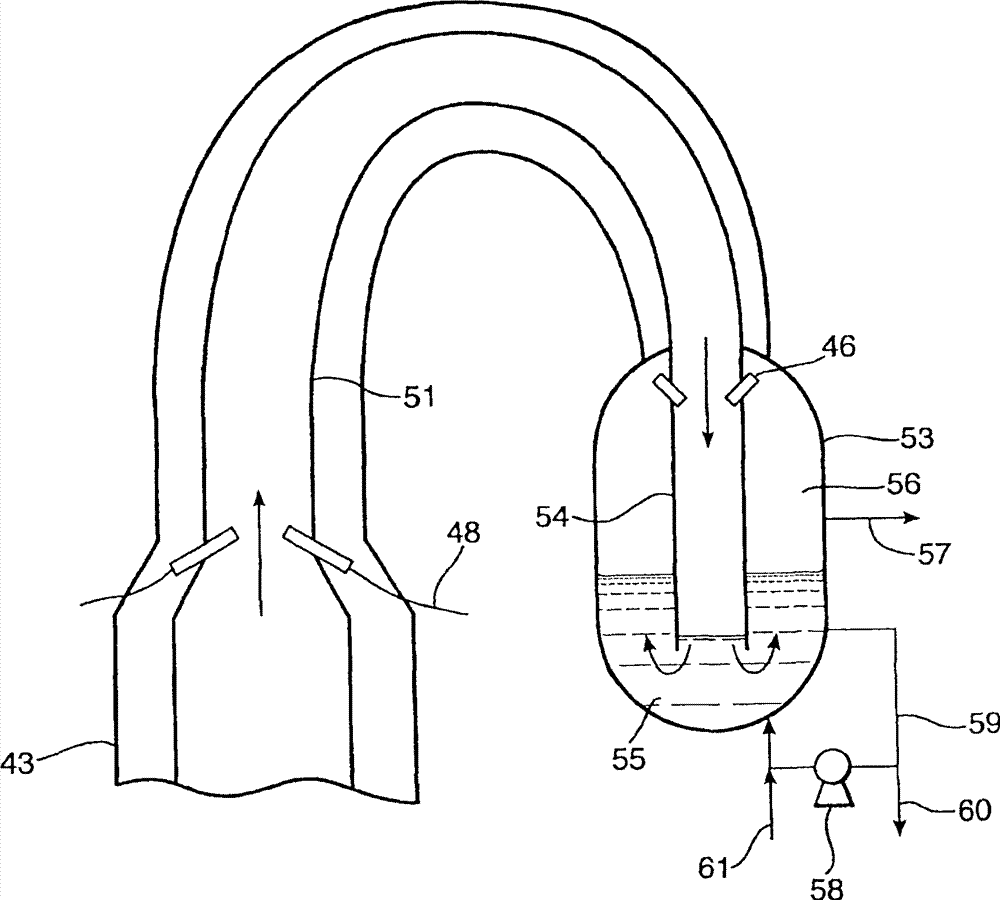

[0022] The gasification reactor of the invention is suitable for producing a mixture comprising carbon monoxide and hydrogen by partial oxidation of a solid hydrocarbonaceous feed in the gasification reactor of the invention or in the system of the invention. In the process, a solid hydrocarbonaceous feed is partially oxidized with an oxygen-containing gas in a gasification chamber to form an upwardly moving gas mixture having a temperature of 1200-1800°C, preferably 1400-1800°C. The mixture is preferably cooled in a first cooling step. The gas is preferably further cooled to below 500°C in a separate cooling vessel.

[0023] The solid hydrocarbonaceous feed is partially oxidized with an oxygen-containing gas. Preferred hydrocarbonaceous feedstocks are solid high carbonaceous feedstocks, more preferably consisting essentially (ie >90wt%) of naturally occurring coal or synthetic (petroleum) coke, most preferably coal. Suitable coals include lignite, bituminous, sub-bituminous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com