Multilayer thermal press hydraulic servo system with synchronous speed, position and pressure control

A technology of hydraulic servo system and multi-layer hot press, which is applied to servo motors, veneer presses, plywood presses, etc., can solve the problem that the hot press plate cannot be closed, affects the speed of movement, and it is difficult to ensure the flow rate of each hydraulic cylinder Consistent and other issues, to achieve the effect of high work stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

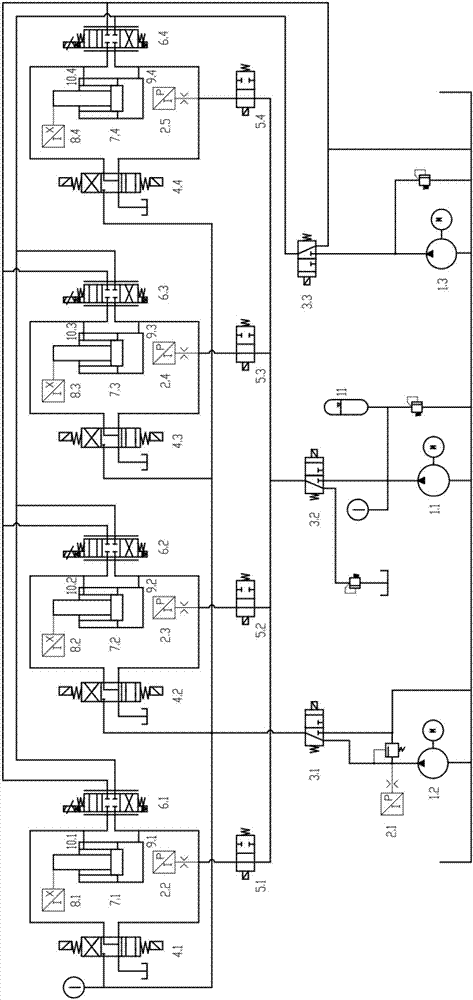

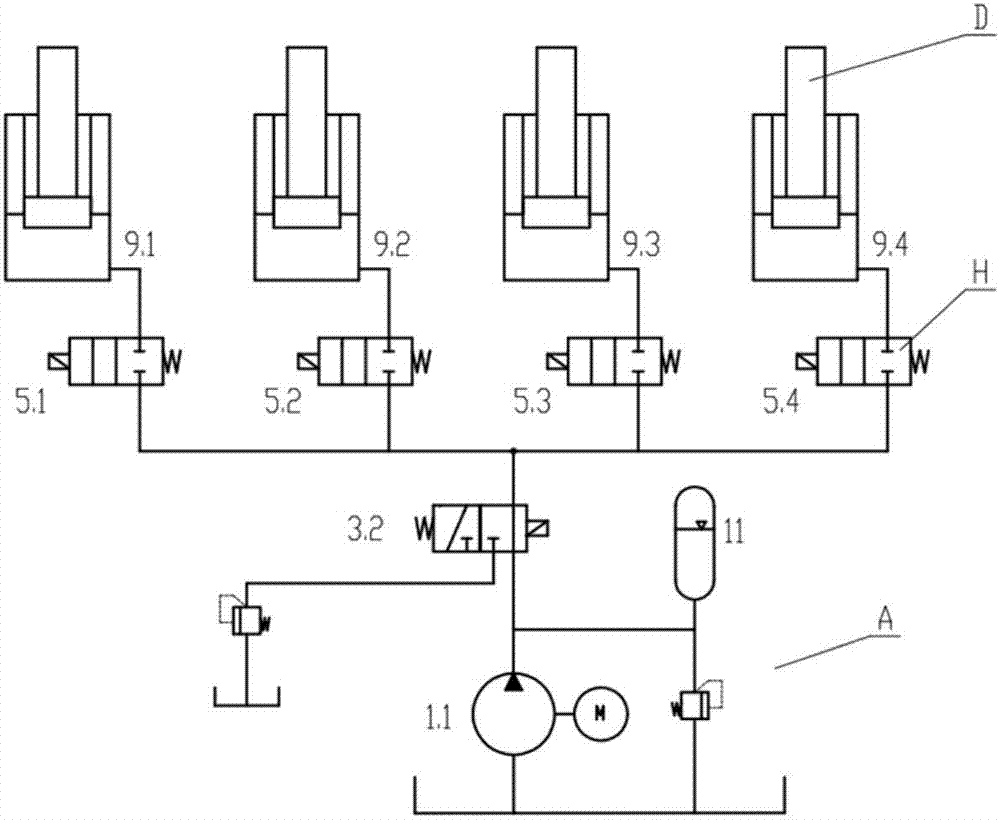

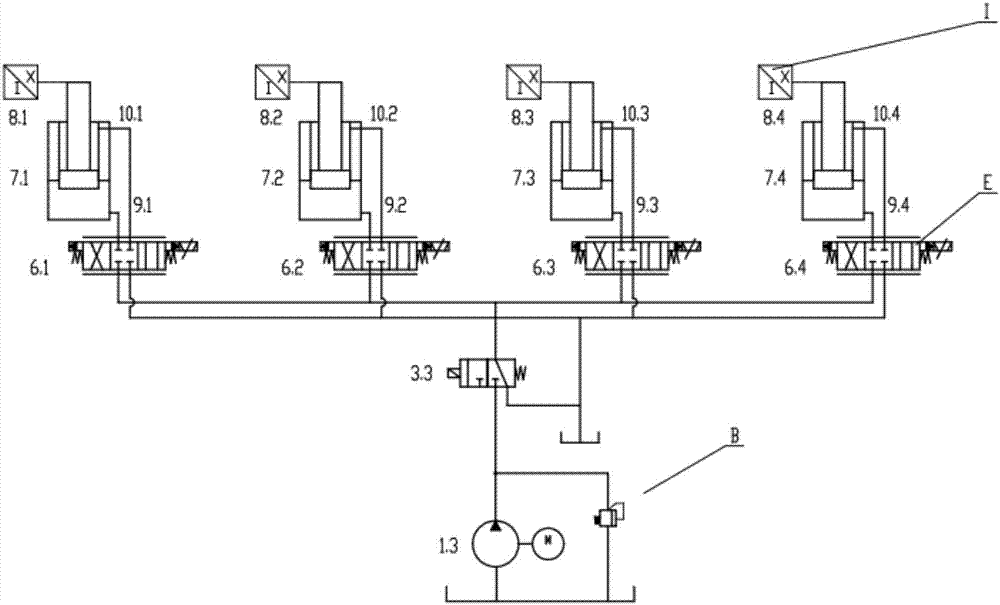

[0036] Example 1: Combining Figure 1 to Figure 5 To illustrate, the multi-layer hot press hydraulic servo system with synchronous speed, position and pressure control includes hot press plate fast closing hydraulic circuit A, hot press multi-cylinder movement synchronous hydraulic servo circuit B, hot press plate closed position accuracy adjustment Hydraulic circuit C, and multiple servo hydraulic cylinders D;

[0037] More specifically, the hydraulic servo system of the multi-layer heat press includes:

[0038] Three hydraulic pumps, respectively defined as the first hydraulic pump 1.1, the second hydraulic pump 1.2 and the third hydraulic pump 1.3;

[0039] Five pressure sensors, respectively defined as a first pressure sensor 2.1, a second pressure sensor 2.2, a third pressure sensor 2.3, a fourth pressure sensor 2.4 and a fifth pressure sensor 2.5;

[0040] Three two-position three-way electromagnetic reversing valves are defined as the first two-position three-way elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com