Hydraulic oil cooling system of crusher

A technology of cooling system and hydraulic oil, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc. It can solve the problems of reduced heat exchange effect, corrosion of pipelines, and poor water quality, and achieves convenient maintenance Maintenance, improvement of work stability and reliability, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

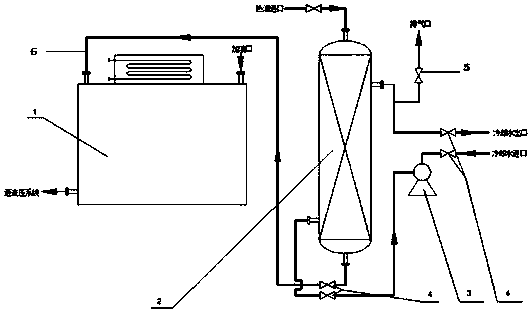

[0021] A hydraulic oil cooling system for a crusher, including a hydraulic station, a shell-and-tube heat exchanger, a delivery pump, pipelines, valves, and an exhaust port. The hydraulic station and the shell-and-tube heat exchanger are connected through pipelines, and the pipeline is set Control valve: use a shell-and-tube heat exchanger with a design pressure of 0.5Mpa, the tube side uses Ф19×2 304 seamless tube, and the shell side is Ф214×5 and the material is 20 (GB / T8163-2008) Seamless pipe; the shell side of the heat exchanger uses cooling water, and the tube side uses hydraulic oil. The vertical installation method is adopted. The lower end of the shell side is connected to the cooling water inlet, and the lower end of the tube side is connected to the hydraulic oil inlet (connected to the hydraulic fuel supply port of the station).

[0022] When working, the temperature of the cooling water is controlled to be 28°C; the flow rate of the cooling water is 5m³ / h; the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com