Novel manufacturing method for fish taxidermy prosthesis specimens

A technique for making specimens and prostheses, applied in teaching models, educational tools, instruments, etc., can solve the problems of affecting the service life of specimens, the specimens are prone to mildew, insects, and not suitable for flat shapes, etc., to extend the storage time, The method is simple and the effect of less tools and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take the dead body of a 31.5kg dead carp as an example:

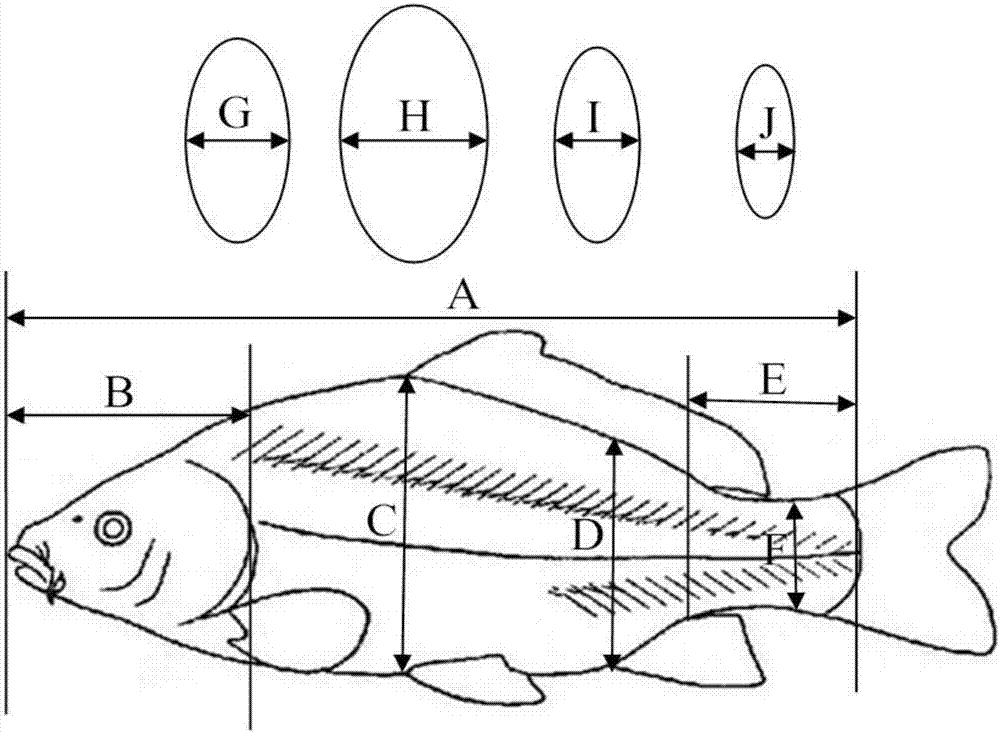

[0057] 1. If figure 1 As shown in the figure, after taking pictures of the dead and complete carp fish and recording the body color, the measurement of fish body parameters is completed, and the steps are as follows:

[0058] 1.1 Measure the body length and head length of fish specimens as 132.1cm and 27.8cm respectively;

[0059] 1.2 Measure the height, width and circumference of the specimen at the gill cover to be 19.5cm, 17.8cm and 60.8cm respectively;

[0060] 1.3 Measure the body height, body width and circumference of the first dorsal fin of the specimen to be 23.5cm, 24.0cm and 73.5cm respectively;

[0061]1.4 Measure the body height, body width and circumference of the anal fin of the specimen to be 14.5cm, 12.0cm and 47.5cm respectively;

[0062] 1.5 Measure the height, width and circumference of the specimen at the caudal peduncle to be 10.5cm, 8.5cm and 29.5cm respectively;

[0063] 1.6 The maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com