Flue gas purification device and process for hot mix plant recycling equipment

A flue gas purification and thermal regeneration technology, applied in the field of flue gas purification devices of plant mixing heat regeneration equipment, can solve the problems of incomplete treatment of dusty flue gas, secondary pollution, etc., so as to improve the purification speed and effect, and accelerate oxidation. The effect of the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

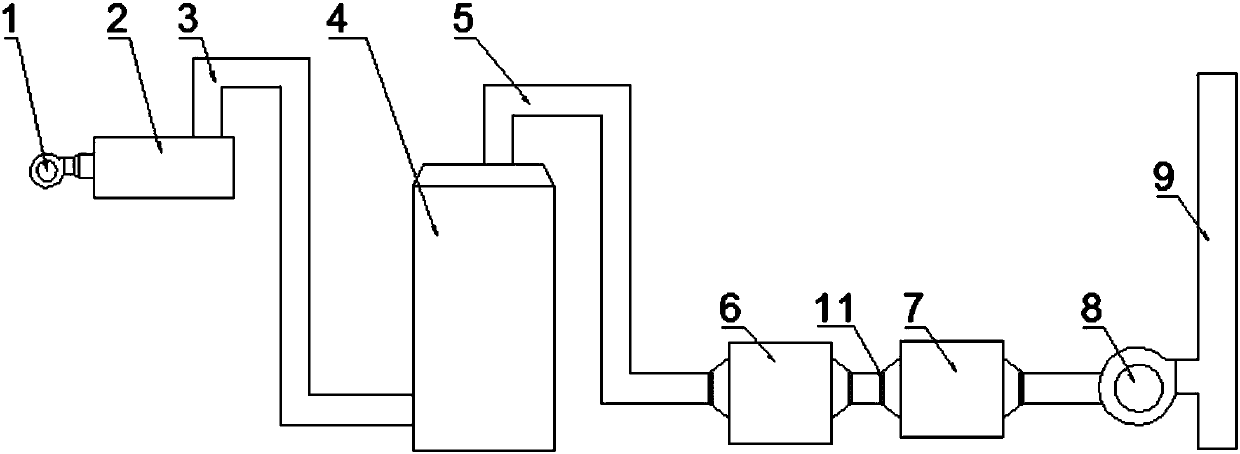

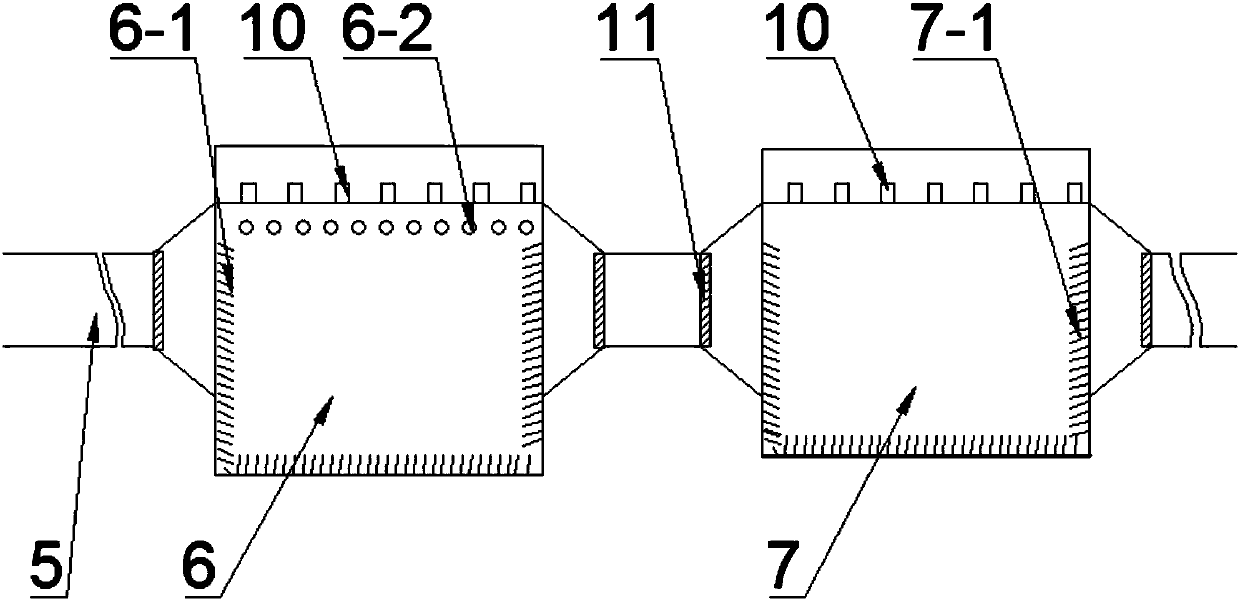

[0026] Such as figure 1 Shown: a flue gas purification device for plant-mixed heat regeneration equipment, characterized in that it includes a burner 1 connected in series, a regeneration drum 2, a first dust induction pipe 3, a spray swirl tower 4, a second induction Dust pipeline 5, first reaction chamber 6, second reaction chamber 7, induced draft fan 8 and chimney 9. The burner 1 is used to generate heat, and the heat is discharged to the inside of the regeneration drum 2 to heat the internal regeneration material. The spray swirl tower 4 uses water to generate a spray to remove large-size dust in the dusty flue gas. The structural composition and working process of the burner 1, the regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com