Process for cathode electrolytic deposition of rare-earth conversion film

A technology of electrolytic deposition and chemical conversion film, which is applied in the field of processing with external direct current, can solve the problems of difficult maintenance of the process, high working temperature, and difficult application, and achieves improved hydrophilicity, improved corrosion resistance, and good binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1. Cathodic electrolytic deposition process of antirust aluminum LF21

[0028] 1.1. The aluminum alloy adopts the anti-rust aluminum alloy of the national standard LF21 aluminum alloy. The test piece is subjected to pre-treatments such as grinding, degreasing, pickling, and alkali washing in sequence. The treatment process is: use water-resistant sandpaper to polish to 800# in sequence → deionized water washing → degreasing with acetone solution → deionized water washing → Na 2 CO 3 、Na 3 PO 4 Washing with mixed solution → washing with deionized water → alkaline washing with 50g / l NaOH solution → washing with deionized water → pickling with 200g / l nitric acid solution → washing with deionized water → drying.

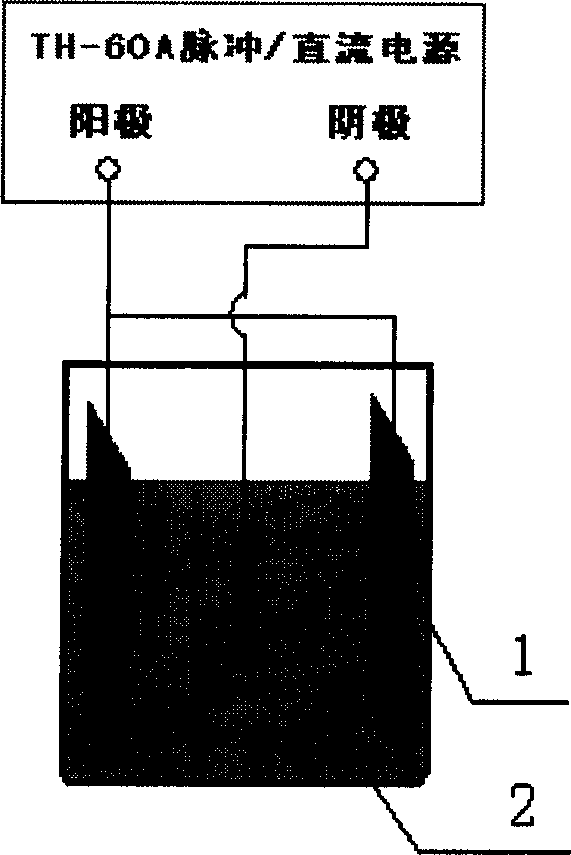

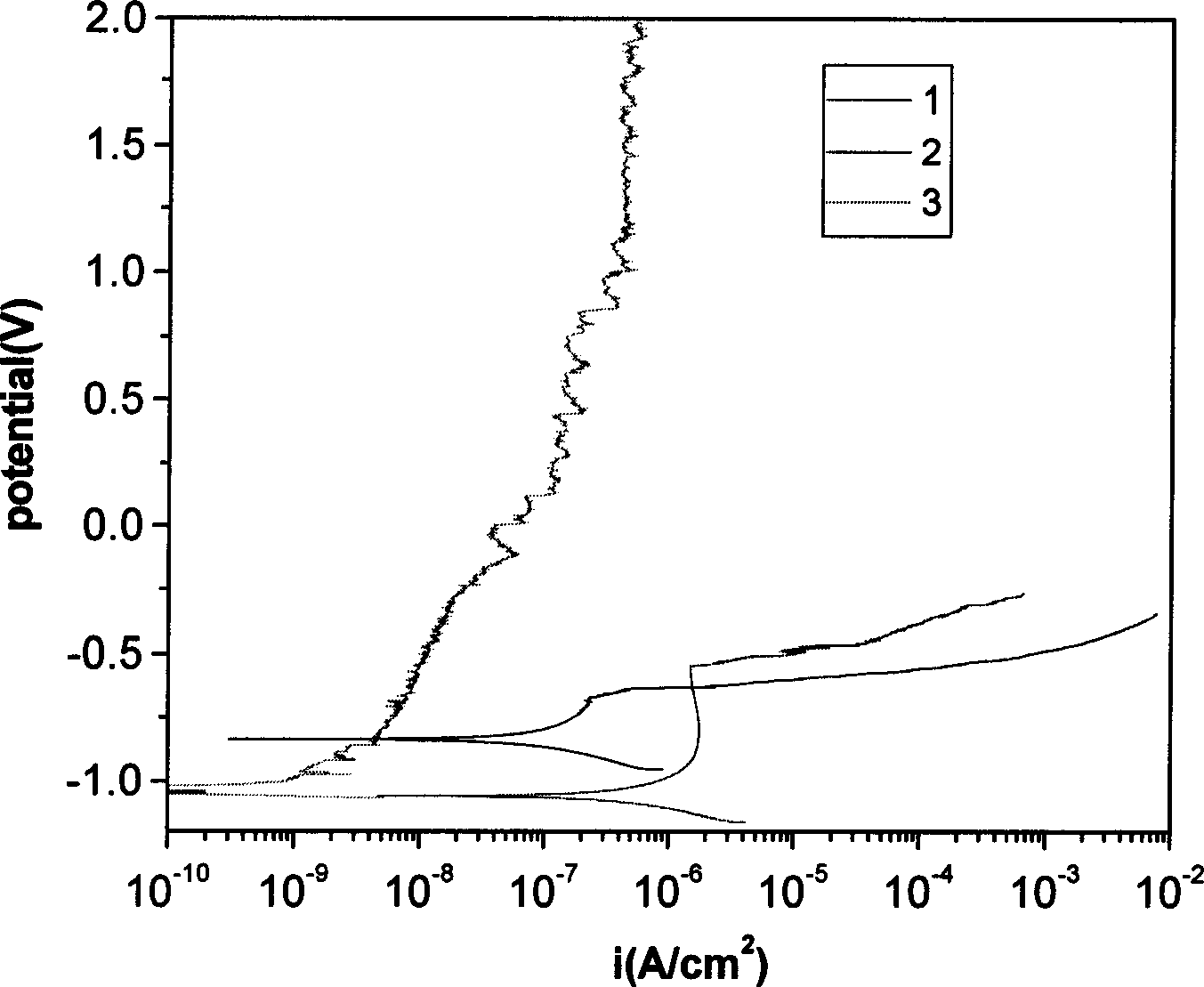

[0029] 1.2. Preparation containing CeCl 3 、H 2 o 2 , The processing solution of citric acid is poured in the beaker in the water bath. and heated to 50°C, the ratio of the treatment solution is: CeCl 3 10g / l,H 2 o 2 60ml / l, corrosion inhibi...

Embodiment 2

[0033] Embodiment 2. Cathodic electrolytic deposition process of antirust aluminum LF21

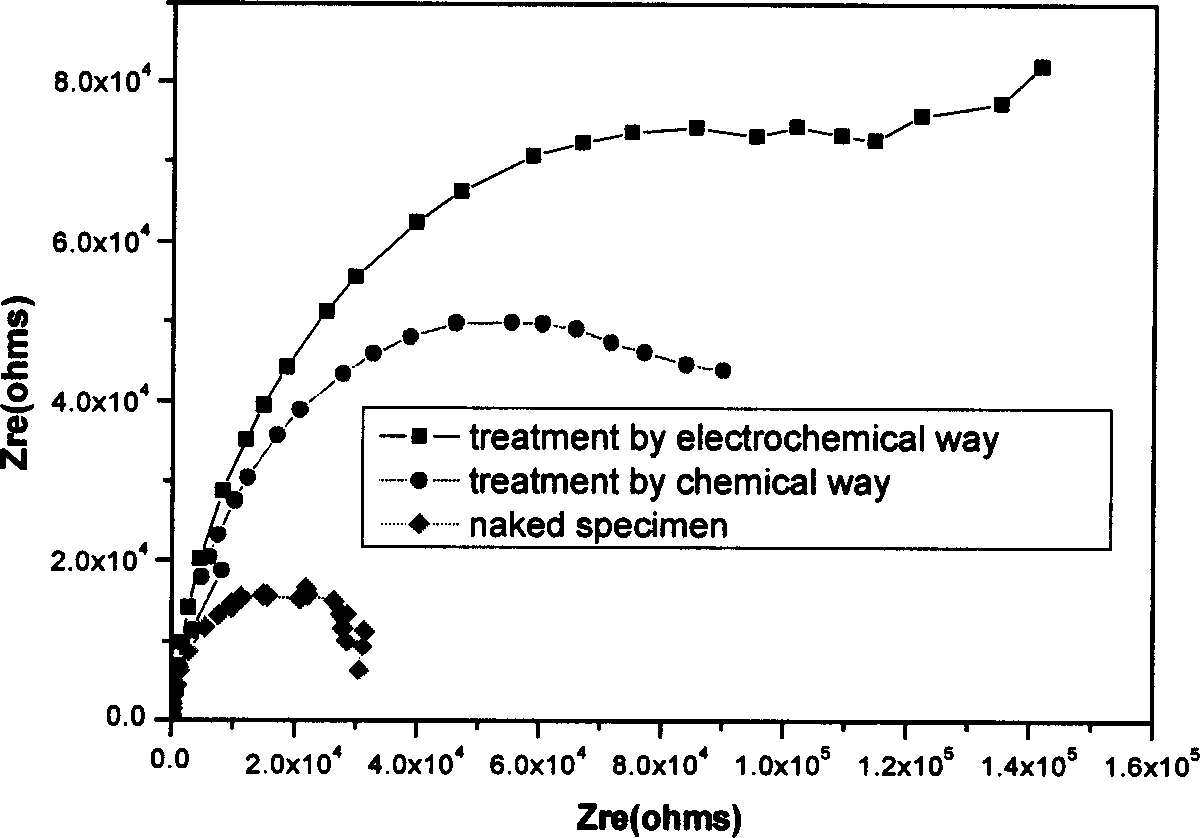

[0034] The aluminum alloy adopts the anti-rust aluminum alloy of the national standard LF21 aluminum alloy. Cathodic electrodeposition treatment at 40°C, CeCl 3 20g / l,H 2 o 2 70ml / l, corrosion inhibitor citric acid 2.5g / l. All the other operating methods and process conditions are the same as in Example 1. The resulting Nyquist diagram is shown in Figure 4 . It can be seen from the figure that the arc radius of the conversion coating sample under electrochemical conditions is larger than that of the conversion coating and blank samples prepared under chemical impregnation conditions. It shows that the corrosion resistance of aluminum alloy is greatly improved after electrochemical treatment.

Embodiment 3

[0035] Embodiment 3. Cathodic electrolytic deposition process of antirust aluminum LF21

[0036] The aluminum alloy adopts the anti-rust aluminum alloy of the national standard LF21 aluminum alloy. Cathodic electrodeposition treatment at 60°C, CeCl 3 15g / l,H 2 o 2 65ml / l, corrosion inhibitor citric acid 2.3g / l. All the other operating methods and process conditions are the same as in Example 1. The resulting Nyquist diagram is shown in Figure 5 . It can be seen from the figure that the arc radius of the conversion coating sample under electrochemical conditions is larger than that of the conversion coating and blank samples prepared under chemical impregnation conditions. It shows that the corrosion resistance of aluminum alloy is greatly improved after electrochemical treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com