Batch arc-shaped plate cutting tool

A technology for cutting tools and plates, which is applied in the field of batch arc-shaped plate cutting tools, can solve the problems of old cutting arcs and increased costs, and achieve the effects of avoiding cutting, low production cost, and improving speed and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

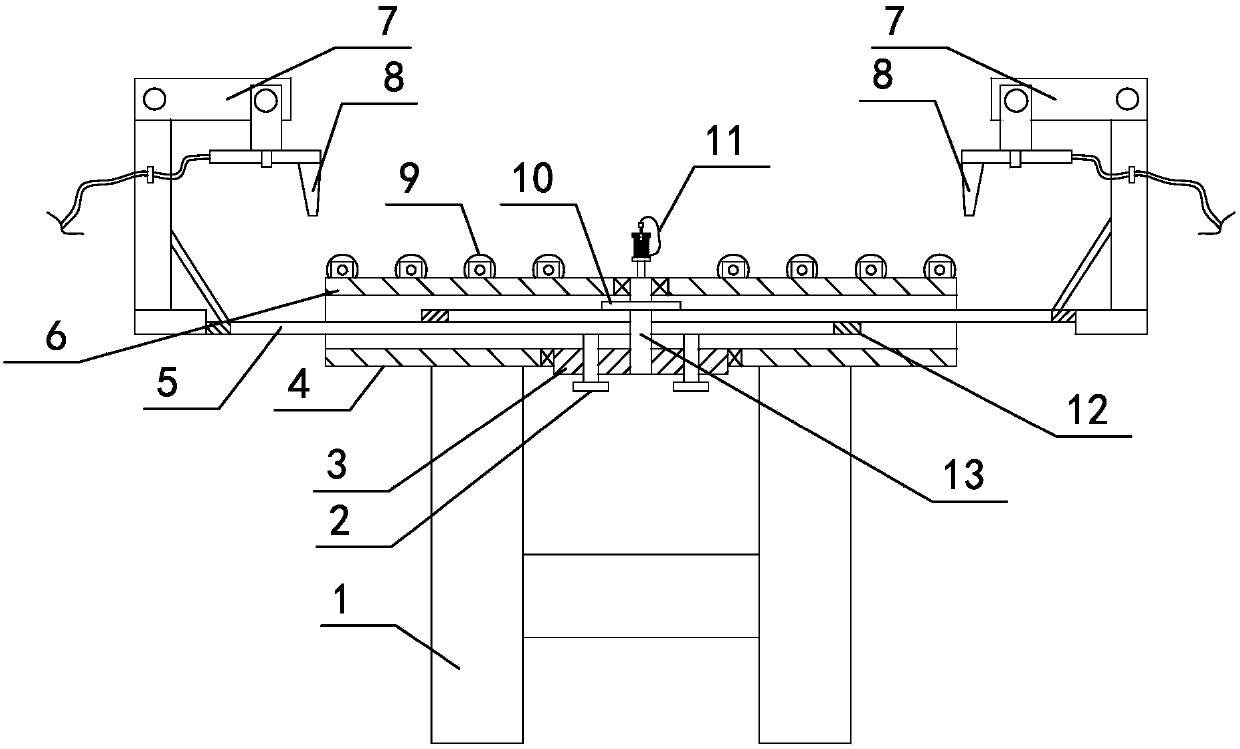

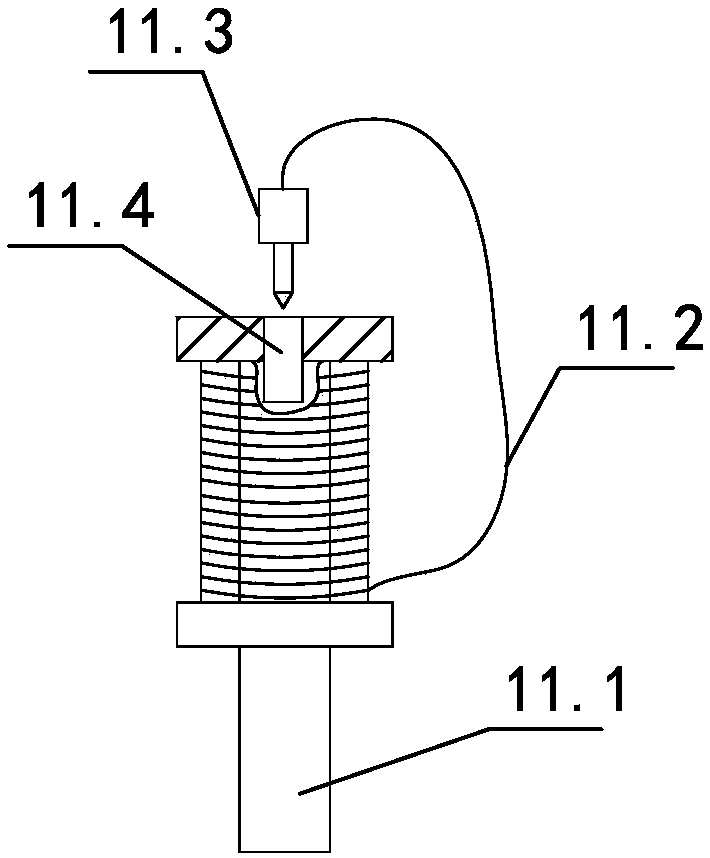

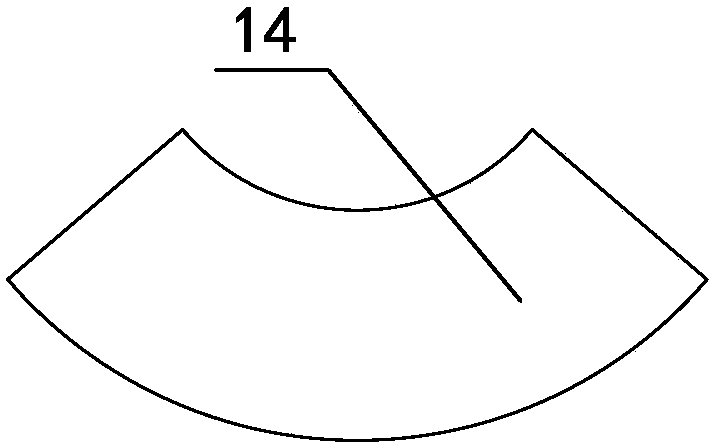

[0021] Such as figure 1 , figure 2 and Figure 4 As shown, the batch arc-shaped plate cutting tool includes a bracket 1, on which a mounting plate 6 and a bottom plate 4 are installed horizontally from top to bottom, and a rotating shaft 13 is vertically installed between the mounting plate 6 and the bottom plate 4 The upper end of the rotating shaft 13 is installed with the mounting plate 6 through the bearing, and the rotating disc 3 is installed at the lower end, and the rotating disc 3 is installed on the base plate 4 through the bearing; Sliding bar 12, each sliding bar 12 is provided with the chute 5 that communicates up and down, and the middle part of rotating shaft 13 is worn in the chute 5; 3 is provided with a locking assembly for locking the position of the sliding bar 12; the outer end of the sliding bar 12 is equipped with a telescopic adjustment bracket 7 that can be flexibly adjusted, and a torch 8 is installed on the telescopic adjustment bracket 7; on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com