Water circulation monitoring control device with flow display function and welding robot

A technology of monitoring, control and display functions, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of inconvenient adjustment of water flow and control on-off, and inability to display cooling water flow in real time, so as to achieve fast and convenient adjustment and functional operation. Simple, reduce labor intensity, reduce the effect of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

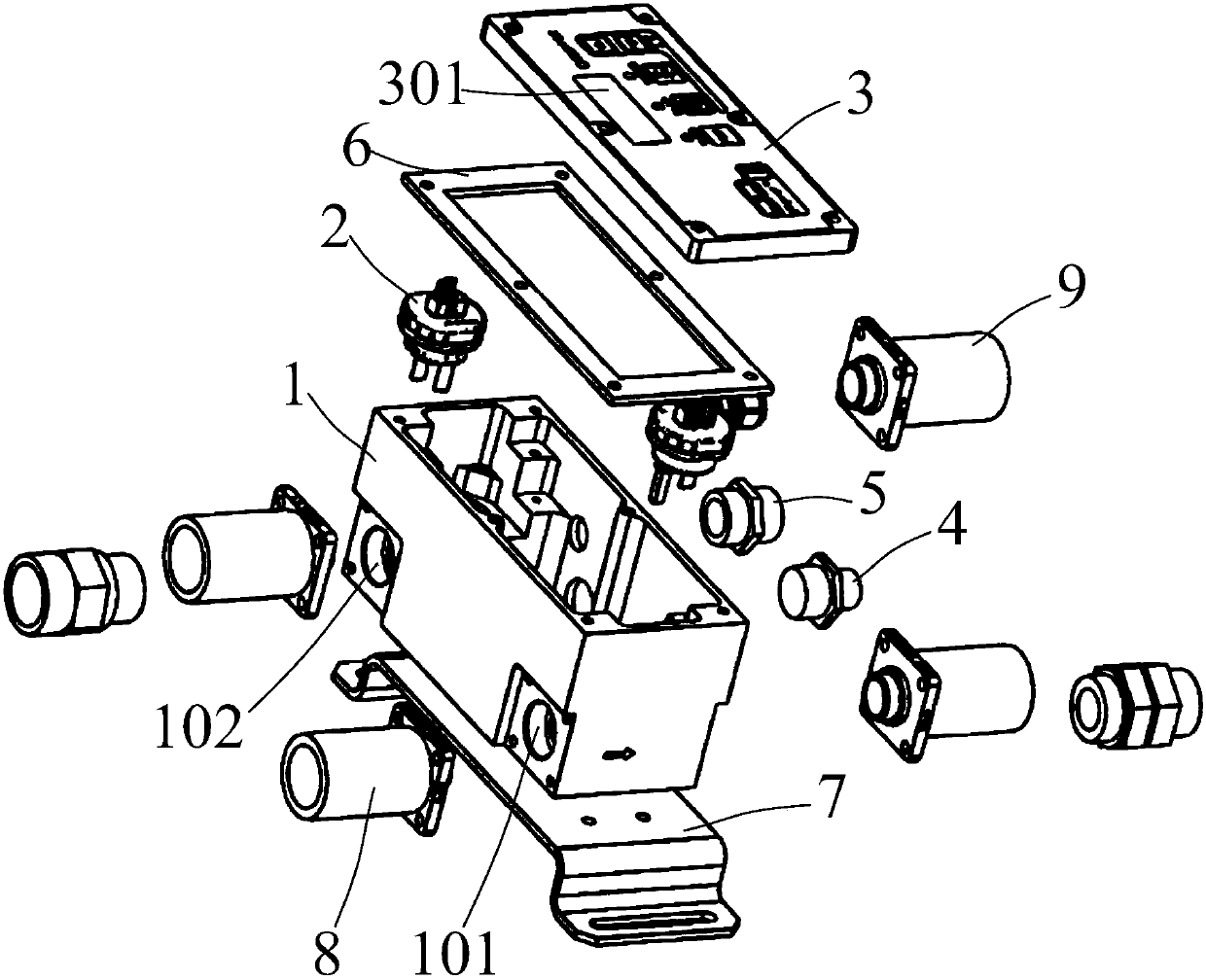

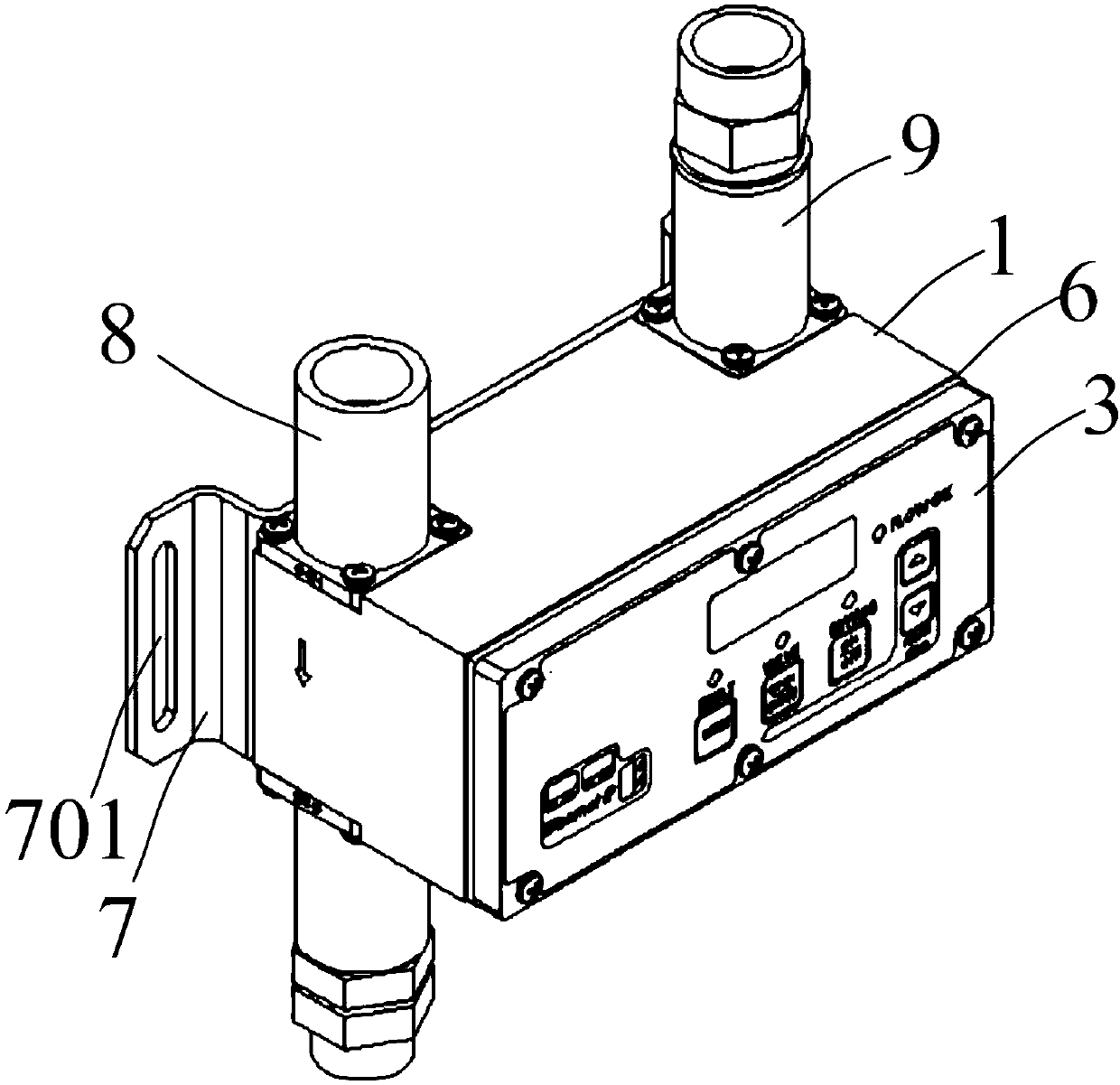

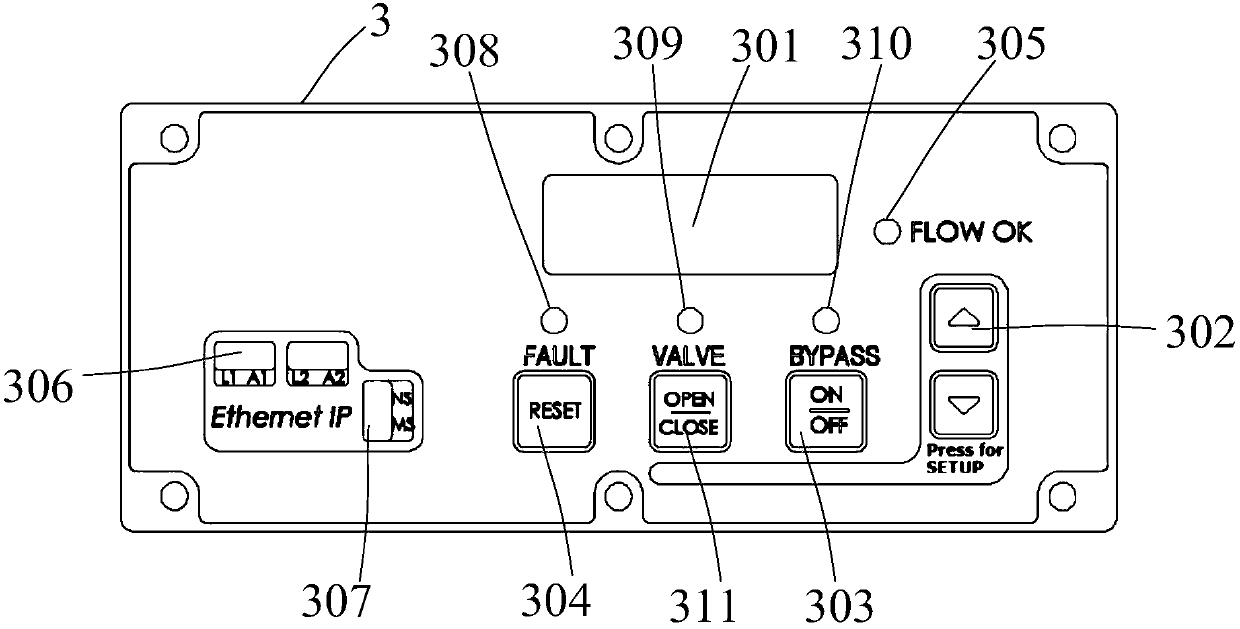

[0025] Such as Figure 1-2 As shown, the water cycle monitoring control device with flow display function involved in this embodiment includes a frame 1, a flow sensor 2 and a control panel 3, and the control panel 3 includes a signal processing circuit (not marked in the figure) and a display unit (not shown in the figure). marked), the flow sensor 2 is electrically connected to the control panel 3, the display unit is electrically connected to the signal processing circuit, the frame 1 is provided with a water inlet channel 101 and a return water channel 102, and the flow sensor 2 is arranged in the frame 1 Here, two flow sensors 2 are selected to monitor the water flow of the water inlet channel 101 and the water return channel 102 respectively and feed back the monitoring signal to the control panel 3, the control panel 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com