Electric brush processing wire drawing machine with laser detection function

A technology of laser detection and wire drawing machine, which is applied in the direction of manufacturing tools, metal processing equipment, and the control of workpiece feed movement, etc. It can solve the problems of laborious adjustment of the workbench, inhalation of large harmful particles, short service life, etc., and achieve easy lifting and labor saving , prevent surface dirt, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

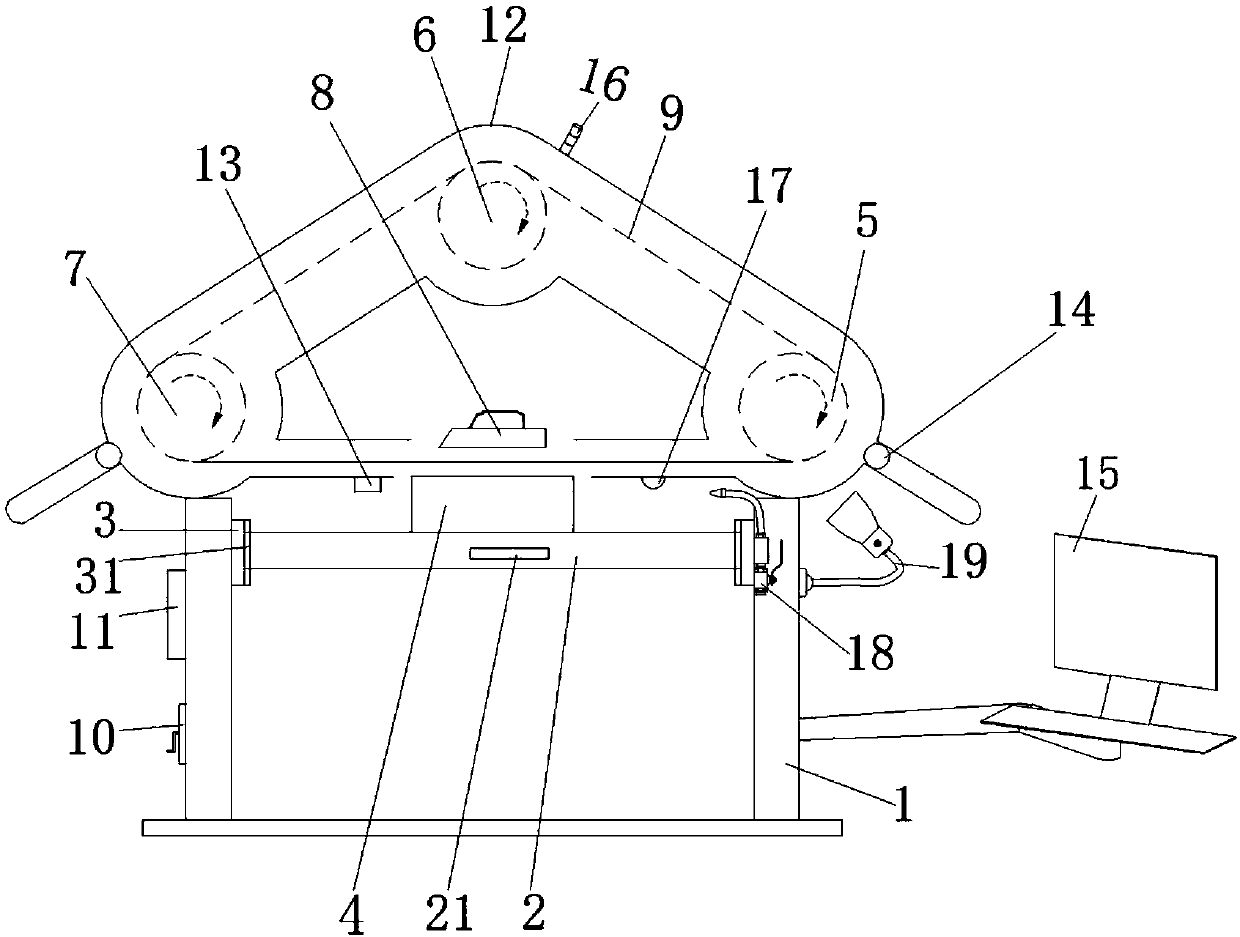

[0030] Such as figure 1As shown, a wire drawing machine with laser detection function for brush processing in this embodiment includes a frame 1, a workbench 2, a handle 21, a fixed block 3, a slide rail 31, a first drum 5, a second Drum 6, third drum 7, hand press plate 8, sandpaper belt 9, crank handle 10, control panel 11, machine cover 12, visual detection mechanism 13, waste removal mechanism 14, display 15, sound and light alarm 16, laser Head 17, cooling mechanism 18 and LED light 19.

[0031] The connecting relation of above-mentioned each parts is as follows: described workbench 2 is slidably connected with frame 1 by the fixed block 3 on both sides, and described workbench 2 side is provided with handle 21, and described workbench 2 is arranged on the surface by fixed block 3. Some slide rails 31 move back and forth; one side of the frame 1 is provided with a crank handle 10 and a control panel 11 in turn, the workpiece 4 is placed in the middle of the workbench 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com