Water removing and weight reducing device for kitchen waste

A technology of food waste and shell, which is applied in the field of dehydration and weight reduction devices for food waste, can solve the problems of high energy consumption and complex structure, and achieve the effects of sufficient drying and weight reduction, high treatment efficiency and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

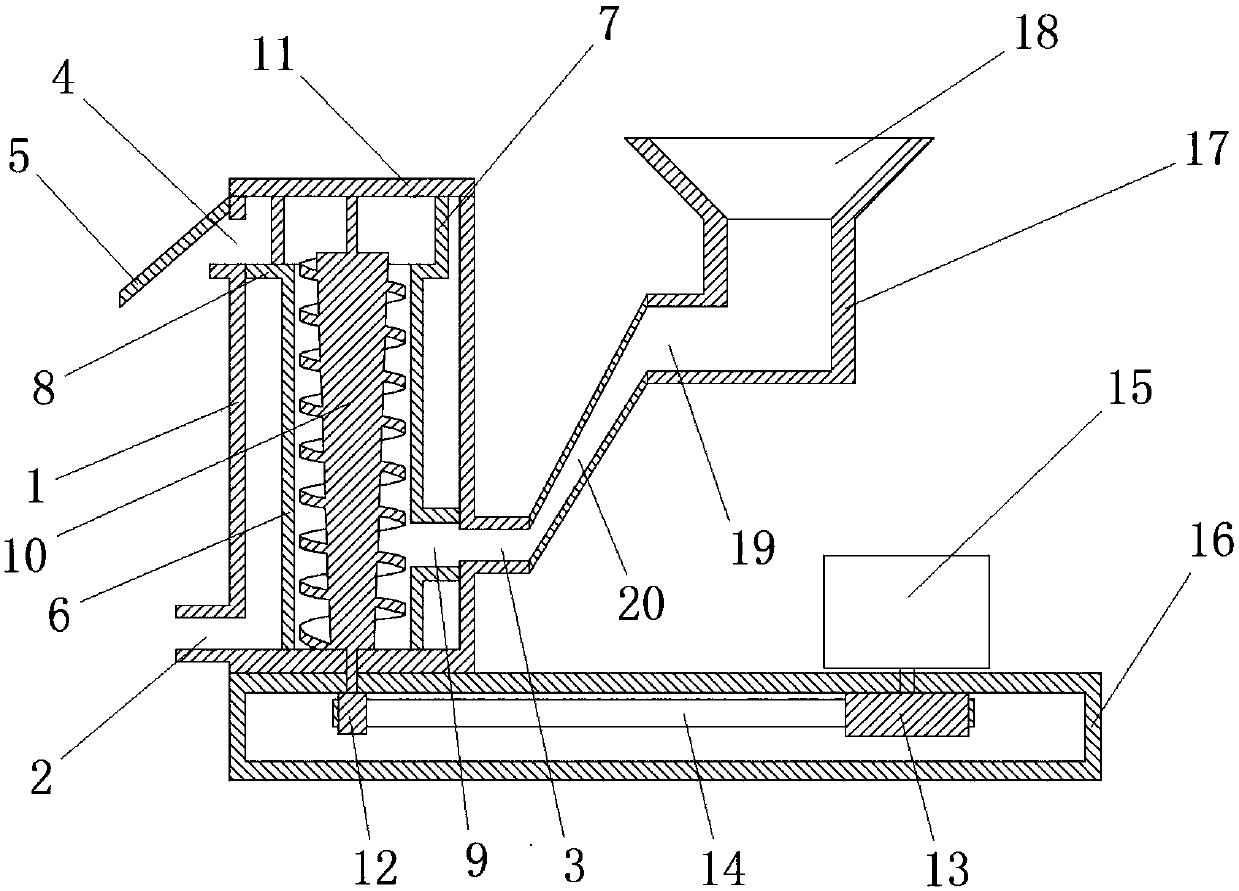

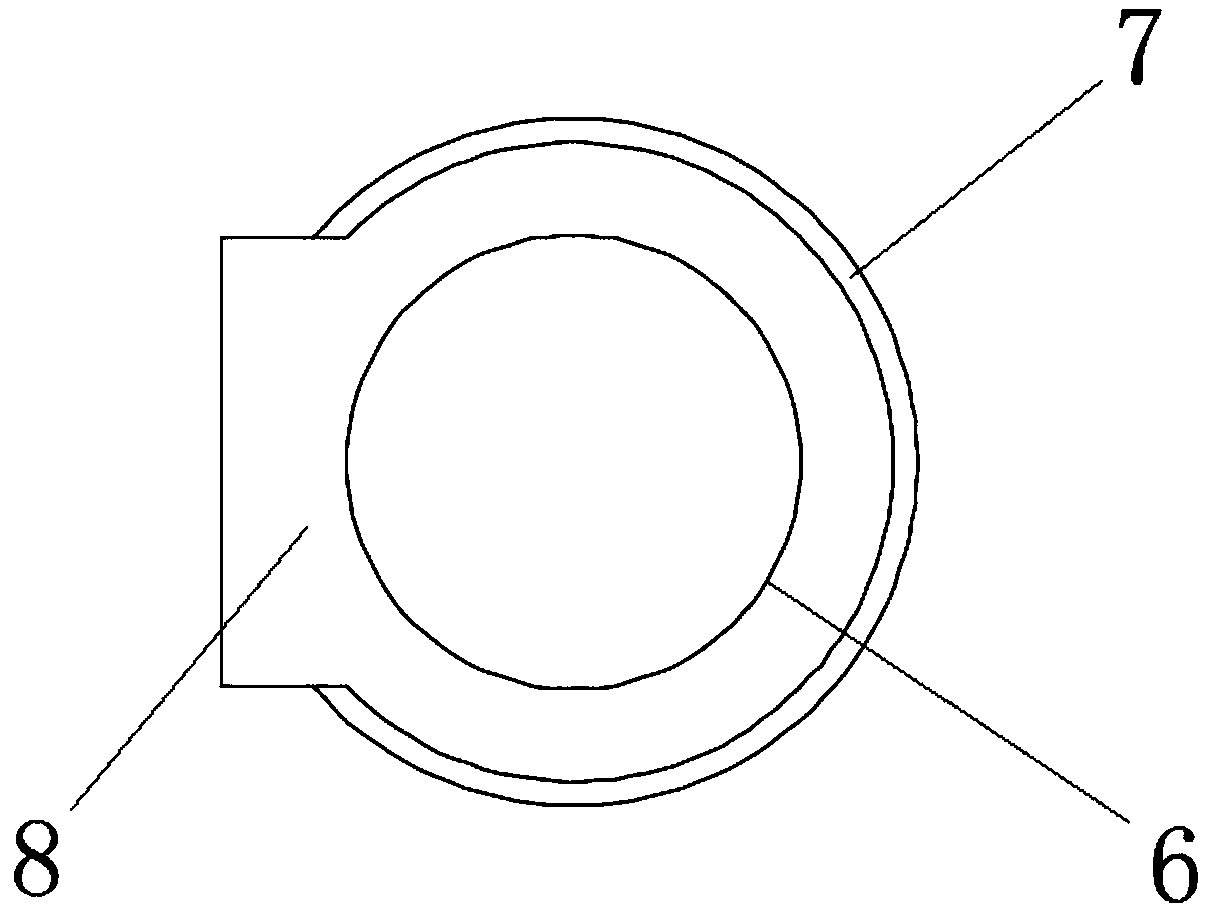

[0027] A dehydration and weight reduction device for kitchen waste, comprising a housing 1, a liquid discharge port 2, a feed port 3, a discharge port 4, a baffle plate 5, an inner sleeve 6, an enclosure 7, a table top 8, and a Feeding port 9, variable diameter screw 10, shaft seat 11, driven timing gear 12, driving timing gear 13, timing belt 14, motor 15, abutment 16, feeding bin 17, funnel 18, feeding port 19, feeding Tube 20, wherein the inner sleeve 6 has a number of through holes on the side wall, the housing 1 and the motor 15 are fixedly connected to the base 16, the lower part of the side wall of the housing 1 has a liquid discharge port 2 and a feed port 3, the shell The upper part of the side wall of the body 1 has a discharge port 4, one end of the baffle plate 5 is fixedly connected to the upper end of the side wall of the housing 1, and the other end is inclined downward, the baffle plate 5 is located at the discharge port 4, and the inner sleeve 6 is socketed in...

Embodiment 2

[0033] A dehydration and weight reduction device for kitchen waste, comprising a housing 1, a liquid discharge port 2, a feed port 3, a discharge port 4, a baffle plate 5, an inner sleeve 6, an enclosure 7, a table top 8, and a Feeding port 9, variable diameter screw 10, shaft seat 11, driven timing gear 12, driving timing gear 13, timing belt 14, motor 15, abutment 16, feeding bin 17, funnel 18, feeding port 19, feeding Pipe 20, wherein, there are several through holes on the side wall of the inner sleeve 6, the housing 1 and the motor 15 are fixedly connected to the base 16, the lower part of the side wall of the housing 1 has a liquid discharge port 2 and a feed port 3, the shell The upper part of the side wall of the body 1 has a discharge port 4, one end of the baffle plate 5 is fixedly connected to the upper end of the side wall of the housing 1, and the other end is inclined downward, the baffle plate 5 is located at the discharge port 4, and the inner sleeve 6 is socke...

Embodiment 3

[0043] A dehydration and weight reduction device for kitchen waste, comprising a housing 1, a liquid discharge port 2, a feed port 3, a discharge port 4, a baffle plate 5, an inner sleeve 6, an enclosure 7, a table top 8, and a Feeding port 9, variable diameter screw 10, shaft seat 11, driven timing gear 12, driving timing gear 13, timing belt 14, motor 15, abutment 16, feeding bin 17, funnel 18, feeding port 19, feeding Tube 20, wherein the inner sleeve 6 has a number of through holes on the side wall, the housing 1 and the motor 15 are fixedly connected to the base 16, the lower part of the side wall of the housing 1 has a liquid discharge port 2 and a feed port 3, the shell The upper part of the side wall of the body 1 has a discharge port 4, one end of the baffle plate 5 is fixedly connected to the upper end of the side wall of the housing 1, and the other end is inclined downward, the baffle plate 5 is located at the discharge port 4, and the inner sleeve 6 is socketed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com