Menthone preparing method

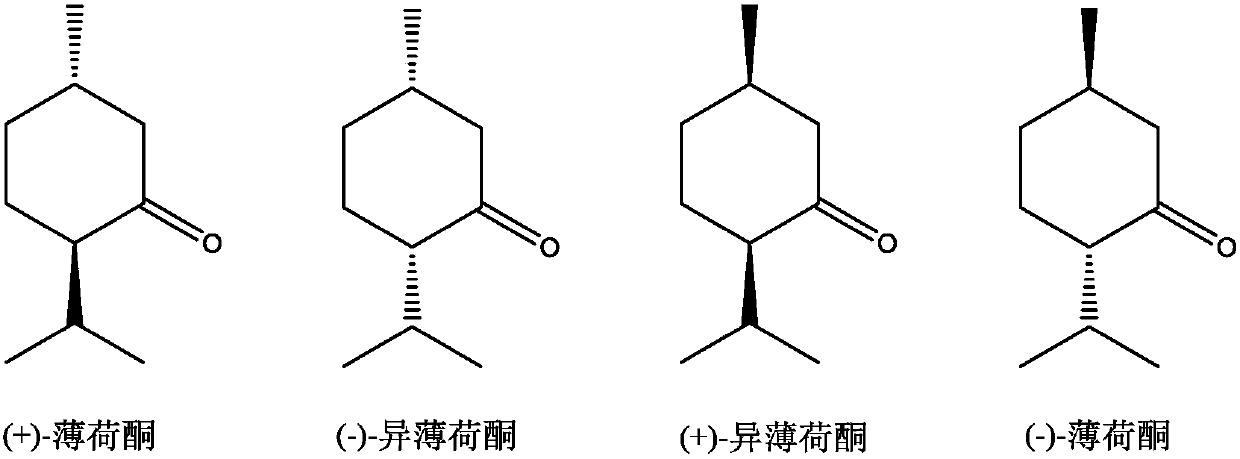

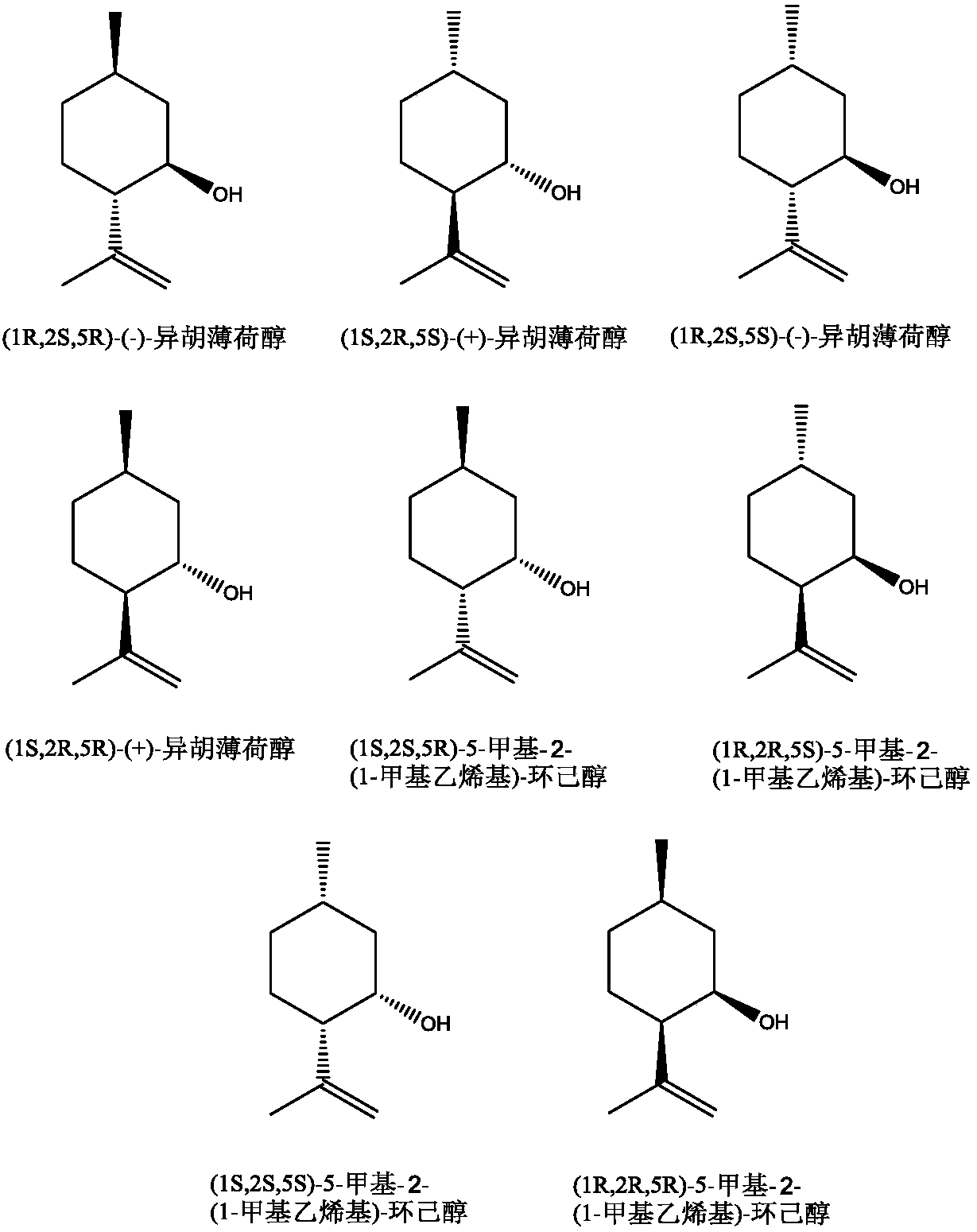

A technology of menthone and isopulegol, which is applied in the field of preparation of menthone, can solve the problems of short catalyst life and adverse environmental impact, and achieve the effects of simplified later stage purification treatment, good industrialization prospects, and remarkable operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

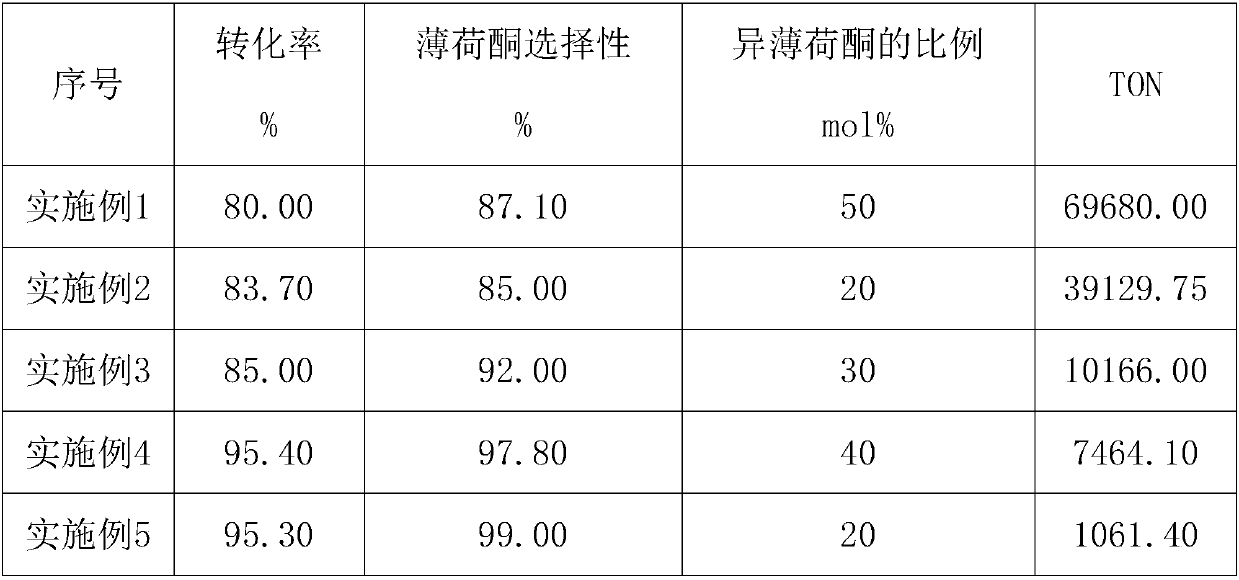

Embodiment 1

[0040] In an oxygen-free and water-free atmosphere, 6.46 mg of triruthenium dodecacarbonyl, 0.013 mg of cyclopentadiene, and 154.25 g of isopulegol were transferred to a 500-mL Schlenk flask equipped with a magnet, and stirred until the mixture was clear and transparent. The absolute pressure of the reaction was maintained at 0.1 Mpa by feeding high-purity nitrogen, and the mixture was heated to 100° C. and stirred for 100 hours. Conversion and menthone yield were determined by calibrated GC analysis. The results are summarized in Table 1.

Embodiment 2

[0042] In an oxygen-free and water-free atmosphere, 5.56 mg of ruthenium acetate, 0.22 mg of cyclooctadiene, and 169.68 g of isopulegol were added to a 500 ml Schlenk flask equipped with a magnet, and stirred until the mixture was clear and transparent. The absolute pressure of the reaction was maintained at 0.2 Mpa by feeding high-purity argon, and the mixture was heated to 140° C. and stirred for 80 hours. Conversion and menthol yield were determined by calibrated GC analysis. The results are summarized in Table 1.

Embodiment 3

[0044] In an oxygen-free and water-free atmosphere, 20.7 mg of ruthenium chloride, 13.8 mg of cyclopentene and 200.53 g of isopulegol were added to a 500 ml Schlenk flask equipped with a magnet, and stirred until the mixture was clear and transparent. The absolute pressure of the reaction was maintained at 1 Mpa by feeding high-purity nitrogen, and the mixture was heated to 160° C. and stirred for 10 hours. Conversion and menthol yield were determined by calibrated GC analysis. The results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com