Preparation method and applications of hogwash oil alkyd

A technology of gutter oil and alkyd, which is applied in the ink field, can solve problems such as low production efficiency, poor reactivity, and difficulty in meeting market demand, and achieve the effect of reducing reactivity and stabilizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of waste oil alkyd comprises the steps:

[0035] Step 1: Measure 459.8g of waste oil, add it to the reaction kettle, heat and stir;

[0036] Step 2: When the temperature is raised to 285°C at a constant speed for 1.5-2 hours, add 124.5g of isophthalic acid and continue to raise the temperature;

[0037] Step 3: When the temperature is raised to 285°C at a constant speed for 5-6 hours, start to keep warm;

[0038] Step 4: After keeping warm for 1.5 hours, take a sample to test the acid hydrolysis; if the material remains clear when it cools down to 250°C, the acid hydrolysis has reached the equilibrium end; if the material is turbid, continue to keep warm, and test the acid hydrolysis every half an hour The material is clear and transparent at 250°C;

[0039] Step 5: After the material is clear and transparent at 250°C, and the acid hydrolysis reaches the equilibrium end point, cool down;

[0040] Step 6: When the temperature is lowered to 220°C...

Embodiment 2

[0050] On the basis of Example 1, while adding trimethylolpropane in step 6, add AT-1. Catalyst AT-1 is a compound mixture containing tin octoate and phosphite, mixed according to the equivalent ratio of 2:1, which can greatly promote the esterification of oil components with poor reactivity in alkyd resins. It also contributes to the color retention of alkyds.

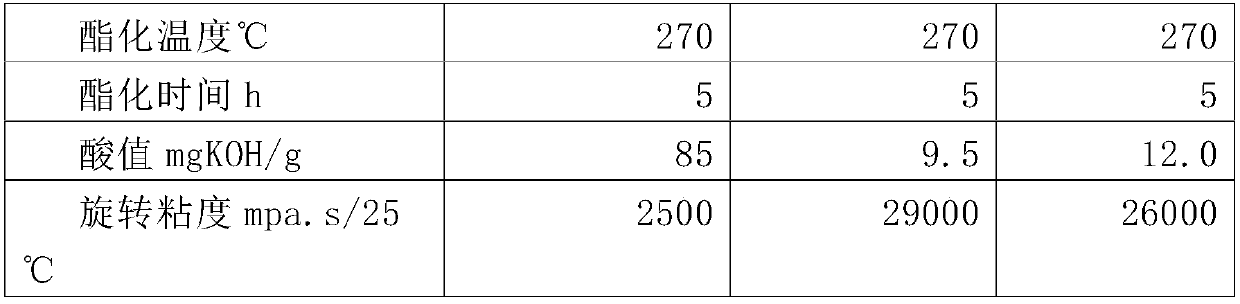

[0051] According to the previous experiment, the experiment added AT-1 to the alkyd synthesized from waste oil, compared with linseed oil and soybean oil.

[0052] Table 2

[0053]

[0054] Through this test, it can be considered that the introduction of AT-1 has played a very important auxiliary role in the esterification of alkyd, greatly improving the reactivity of waste oil and making alkyd in waste oil possible.

[0055] The addition of AT-1 catalyzer has largely solved the drawback of reducing the reactivity brought by waste oil. Because the components in the waste oil are relatively complex, the reactivit...

Embodiment 3

[0057] In order to further verify the performance of waste oil alkyd, we tested three kinds of alkyd in the ink.

[0058] Apply them in the same ratio to the formulation of the binder V338, and use the same process to refine the resin oil.

[0059] In one embodiment, the waste oil alkyd obtained in embodiment 2 is applied to configuration ink, configuration method is as follows:

[0060] Step 1. In a four-neck flask equipped with a mixer and a thermometer, add 78 grams of linseed oil, 30 grams of tung oil, and 32 grams of SJ-5AF mineral oil, and heat evenly to 200 ° C;

[0061]Step 2: Add 215 grams of R2300 resin in batches to dissolve it completely, control the temperature at 200°C, and keep it warm for half an hour;

[0062] Step 3: Add 150 grams of SJ-5AF mineral oil and 62 grams of waste oil alkyd resin to cool down to 150 °C.

[0063] Step 4: Add 5.4 grams of K1541 liquid gel, heat up to 180°C, and keep warm for one hour;

[0064] Step 5. After the heat preservation is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com