Aluminum and aluminum alloy production method

A production method and aluminum alloy technology, which is applied in the field of aluminum and aluminum alloy production, can solve unsatisfactory problems and achieve the effects of improving purity, reducing energy consumption, and avoiding external force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

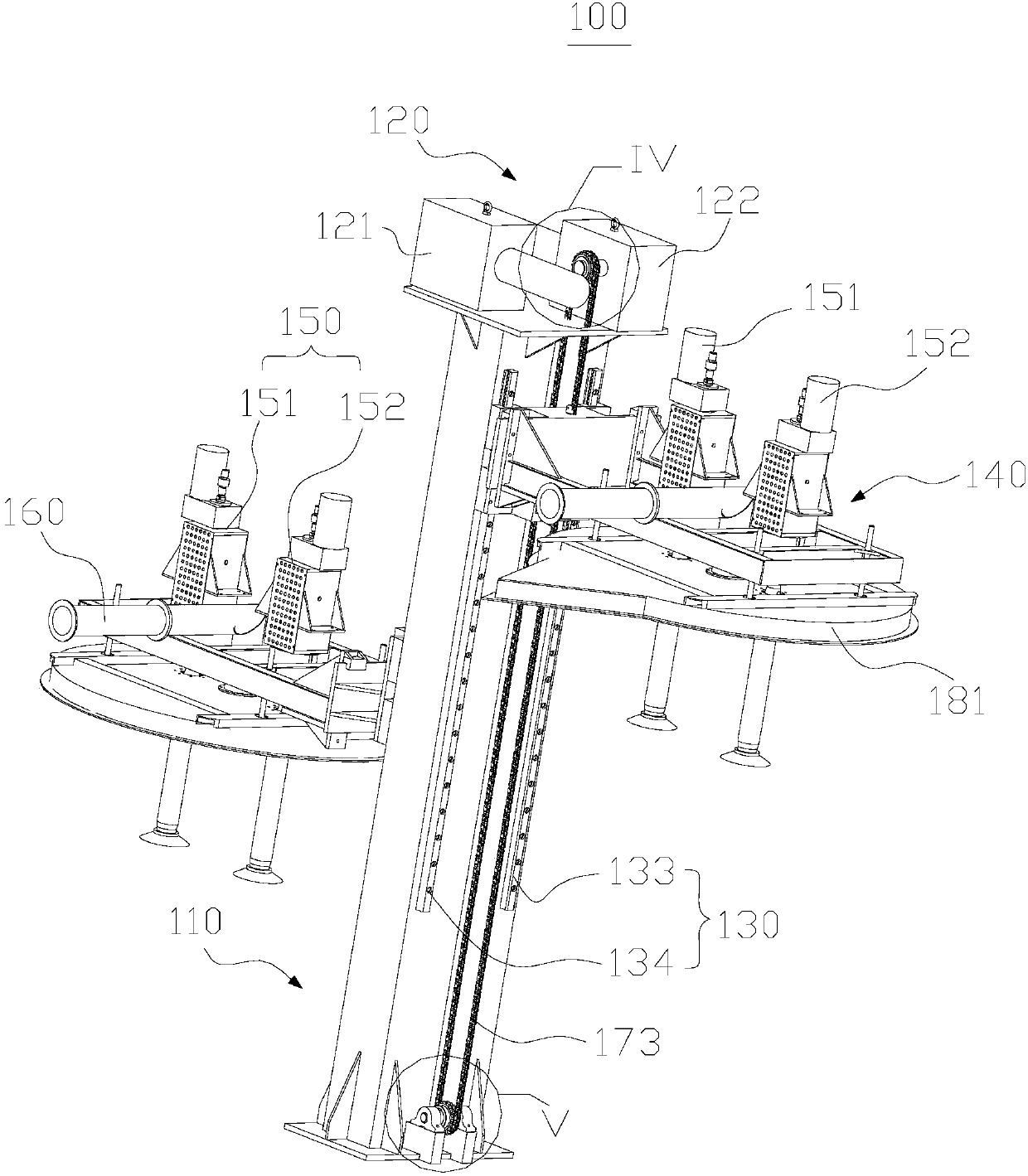

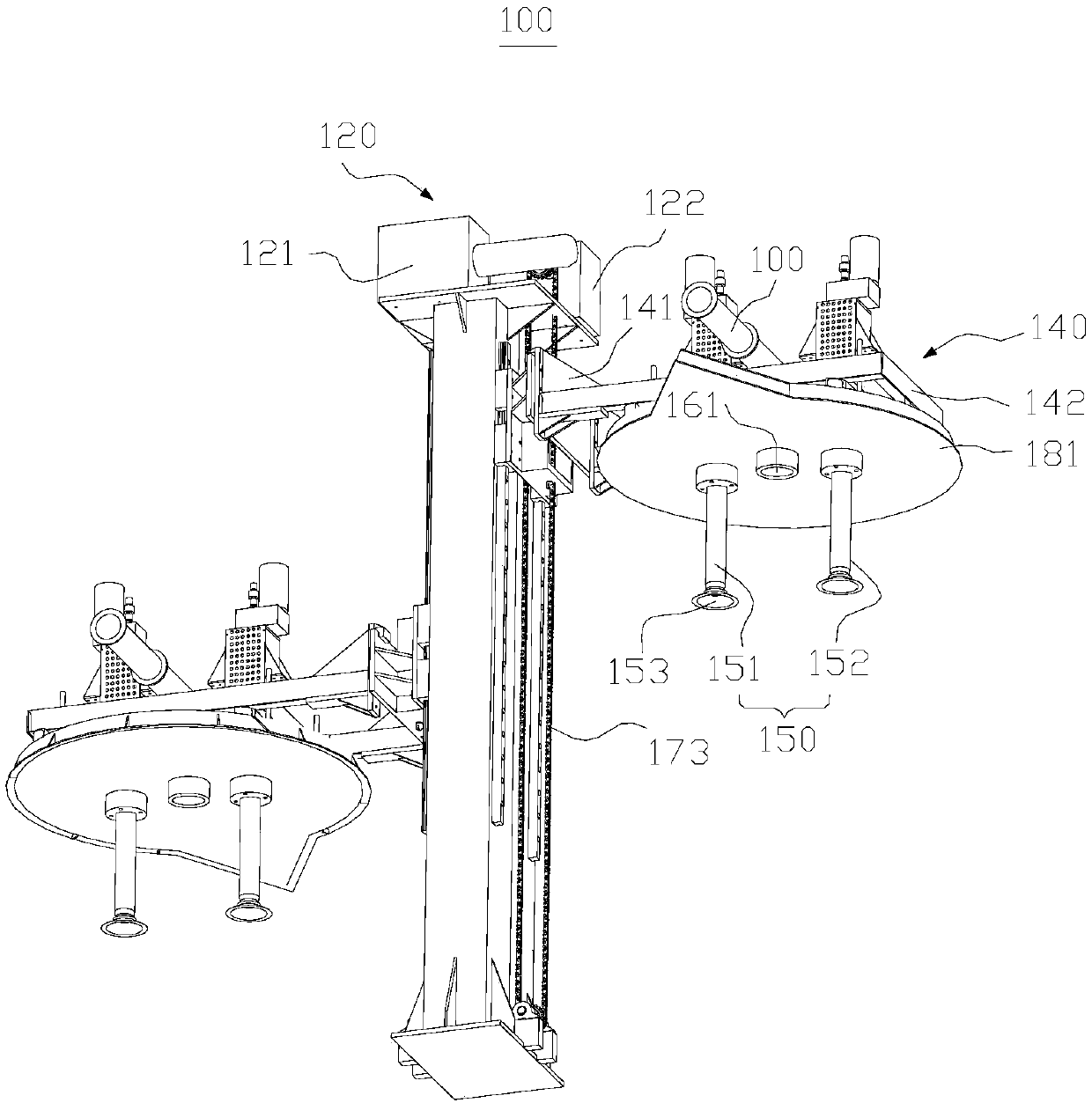

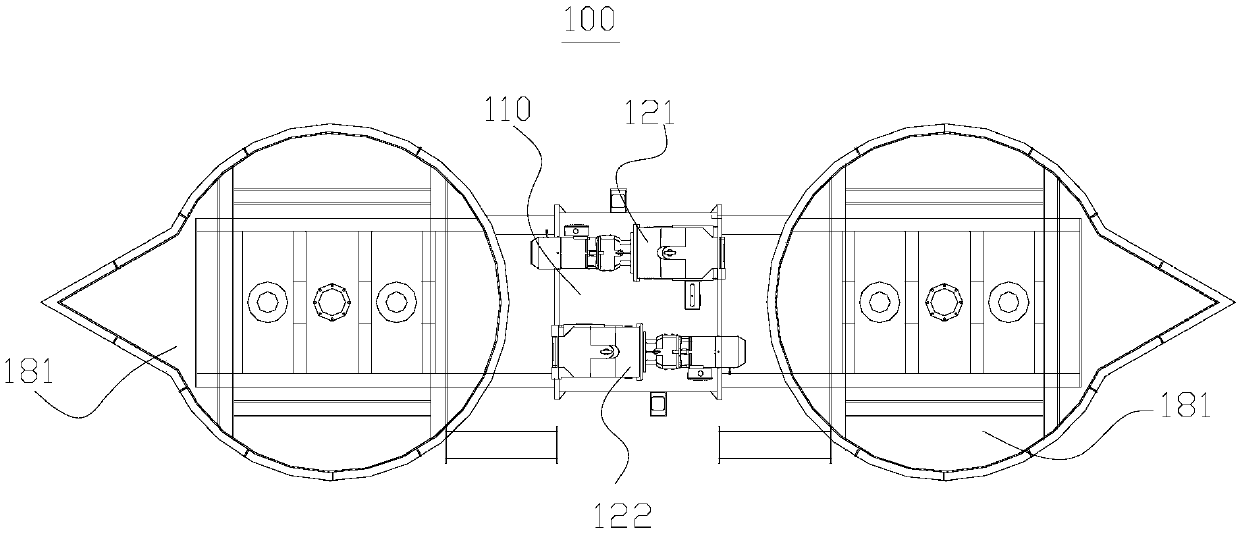

Image

Examples

Embodiment

[0043] The production method of aluminum and aluminum alloy provided in this embodiment, it comprises:

[0044] 1. Alkali removal treatment

[0045] The chlorine-free refining technology is used to fill the aluminum melt to be purified with a mixture of refining agent and inert gas to remove alkali metals, alkaline earth metals and gases in the aluminum melt.

[0046] Wherein, the aluminum melt is electrolytic aluminum liquid. Of course, in other embodiments, the aluminum alloy solution can also be electrolyzed.

[0047] Among them, the refining agent is AlF 3 , the inert gas is argon (Ar).

[0048] AlF 3 As a refining agent, it absorbs, dissolves and chemically reacts with the oxide film and non-metallic inclusions in the melt to achieve the effect of removing impurities such as alkali metals and alkaline earth metals.

[0049] The hydrogen partial pressure difference of the high-purity inert gas in the aluminum melt makes the hydrogen atoms diffuse into the inert gas bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com