Hybrid corn seed production cost-saving, impurity-removing, emasculation and purity-keeping method

A technology of corn and miscellaneous plants, which is applied in the agricultural field, can solve the problems of incomplete detasseling and the difficulty of manual detasseling, and achieve the effects of improving the quality of improved seeds, ensuring the safety of food production, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

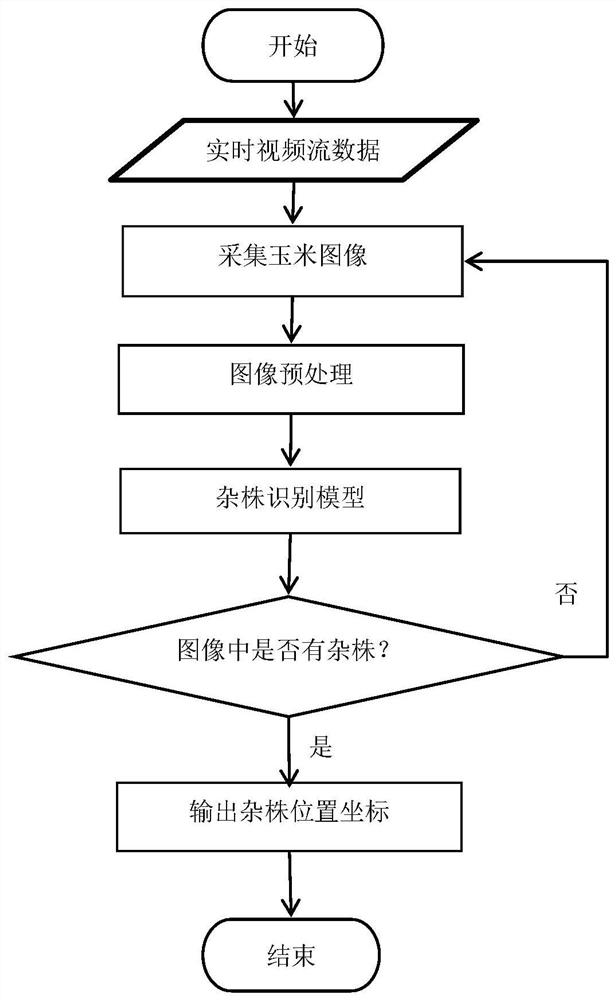

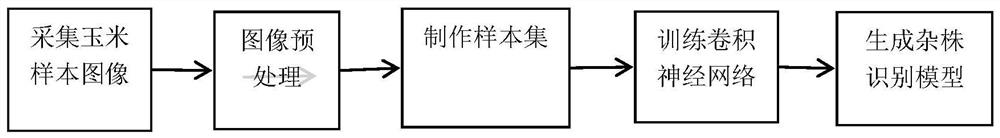

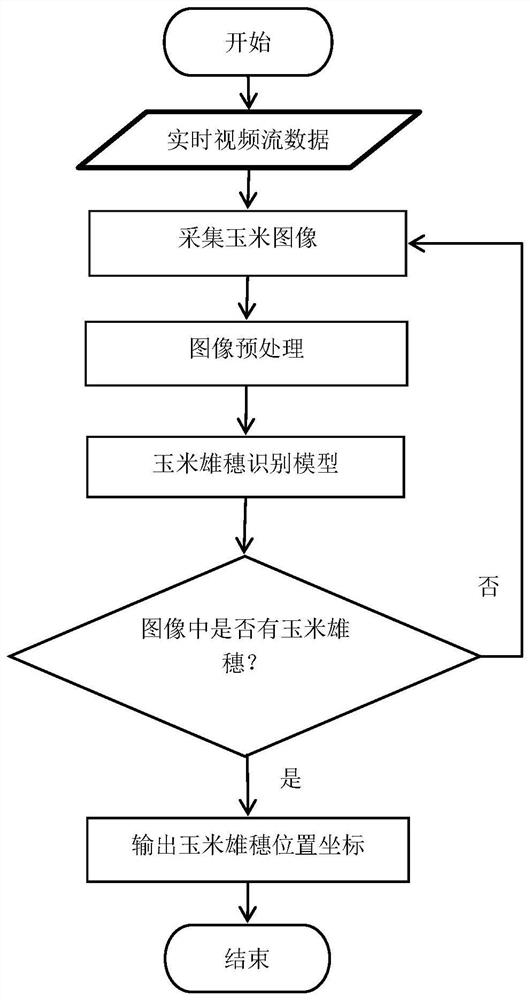

Method used

Image

Examples

Embodiment 1

[0065] The hybrid corn seeds used in this example are the hybrid corn variety "Quanyu 1233" and its male parent "512" and female parent "533".

[0066] 1. Material planting

[0067] In April 2021, the male parent "512" and the female parent "533" of "Quanyu 1233" were sown directly at the corn seed production base, and they were planted in two fields (field A and field B, both with an area of 2000 square meters) square meters): The male parent "512" was sown on April 17; the female parent "533" was sown on April 15; both parents were planted in the same field (1 row of male parent: 7 rows of female parent), and the distance between rows and plants was 50cm× 19cm. Field A is a control field, and in the process of hybrid seed production, artificial removal of impurities and emasculation methods are used to improve the purity of seed production; Field B is to use the method of the present invention to remove hybrid plants to improve the purity of seed production.

[0068] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com