A method for preparing gradient porous tungsten

A technology of gradient porous and porous tungsten is applied in the field of preparing gradient porous tungsten, which can solve the problem of insufficient pore characteristics of gradient porous tungsten.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

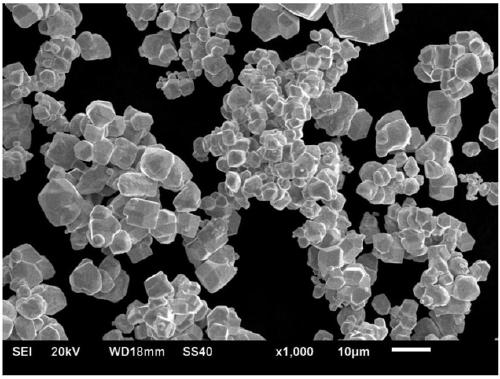

[0027] 1) Raw material powder: The raw material powder is commercially available tungsten powder with a particle size of 5 μm and a purity greater than 99.9%;

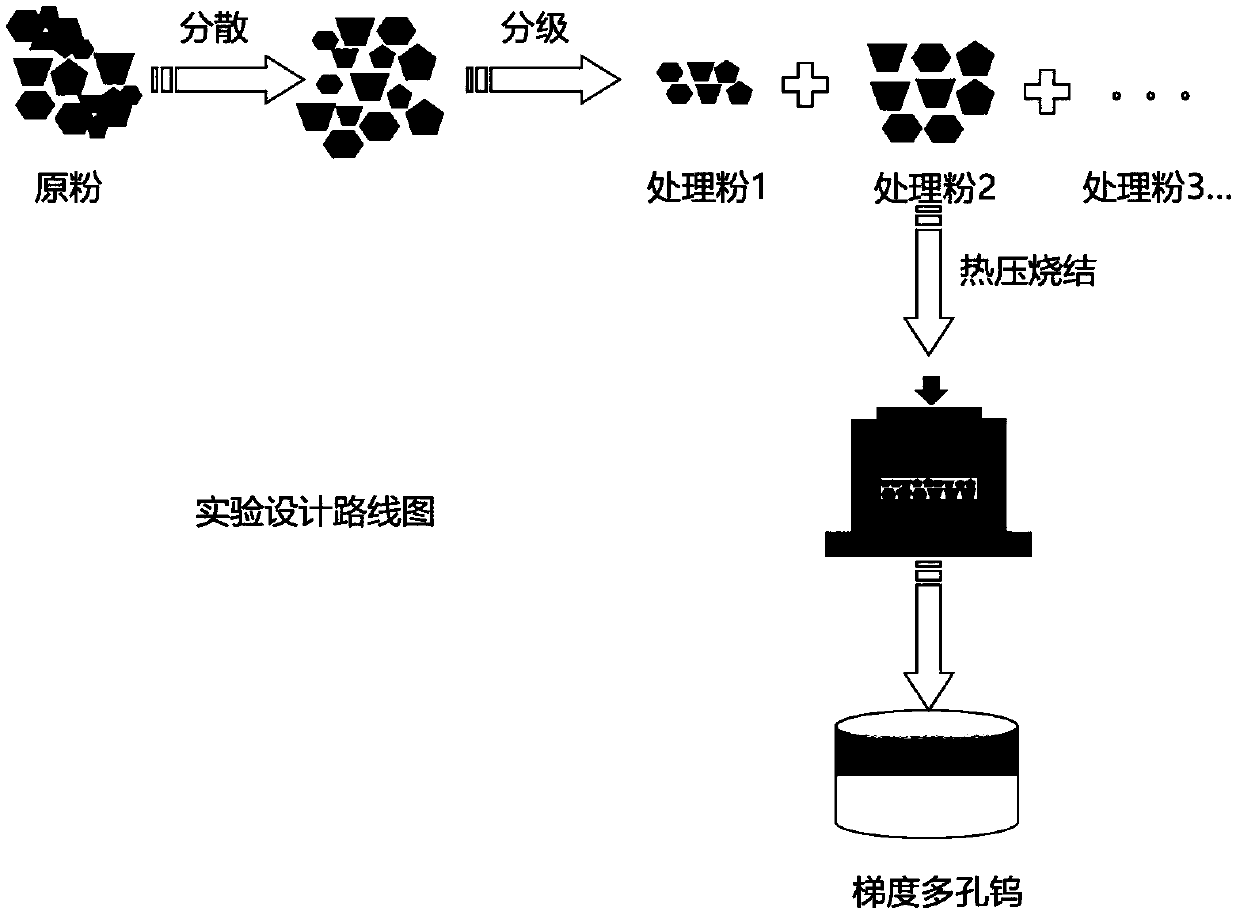

[0028] 2) Jet mill dispersion treatment: Clean the jet mill equipment, turn on the main control to preheat, fill high-purity nitrogen with a purity higher than 99.9% as the working gas, reduce the oxygen content to 0.1%, open the grinding valve, and adjust the grinding pressure to 0.70MPa , add high-purity tungsten powder into the grinding chamber for grinding to make the agglomerates open, adjust the rotation speed of the sorting wheel to 6000r / min, and start the sorting wheel;

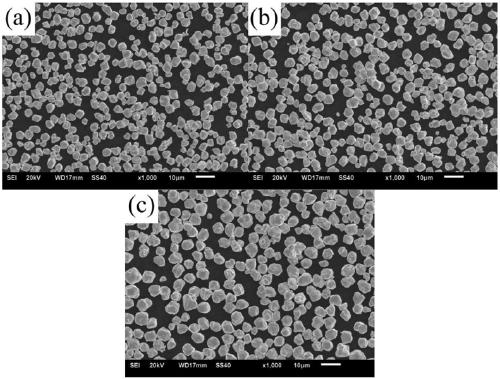

[0029] 3) Jet mill classification treatment: reduce the rotation speed of the sorting wheel several times to 5000r / min, 4000r / min, 3000r / min, 2000r / min and 1000r / min, and collect tungsten powder in five batches;

[0030] 4) Compression forming: select tungsten powder collected at 4000r / min, 2000r / min and 1000r / min for three-layer powder sprea...

Embodiment 2

[0033] 1) Raw material powder: The raw material powder is commercially available tungsten powder with a particle size of 5 μm and a purity greater than 99.9%;

[0034] 2) Jet mill dispersion treatment: Clean the jet mill equipment, turn on the main control to preheat, fill high-purity nitrogen with a purity higher than 99.9% as the working gas, reduce the oxygen content to 0.1%, open the grinding valve, and adjust the grinding pressure to 0.60~ 0.80MPa, add high-purity tungsten powder into the grinding chamber for grinding to make the agglomerates open, adjust the rotation speed of the sorting wheel to 6000r / min, and start the sorting wheel;

[0035] 3) Jet mill classification treatment: reduce the rotation speed of the sorting wheel several times to 5000r / min, 4000r / min, 3000r / min, 2000r / min and 1000r / min, and collect tungsten powder in five batches;

[0036] 4) Hot pressing sintering: choose to collect tungsten powder at 4000r / min, 3000r / min, 2000r / min and 1000r / min for stac...

Embodiment 3

[0038] 1) Raw material powder: The raw material powder is commercially available tungsten powder with a particle size of 8 μm and a purity greater than 99.9%;

[0039] 2) Jet mill to disperse and remove fine powder: Clean the jet mill equipment, turn on the main control to preheat, fill in high-purity nitrogen with a purity higher than 99.9% as the working gas, reduce the oxygen content to 0.1%, open the grinding valve, and adjust the grinding The pressure is 0.60~0.80MPa, add high-purity tungsten powder into the grinding chamber for grinding, so that the agglomerates are opened, adjust the rotation speed of the sorting wheel to 6000r / min, and start the sorting wheel;

[0040] 3) Jet mill classification treatment: reduce the rotation speed of the sorting wheel several times to 6000r / min, 3500r / min, 2800r / min, 2100r / min and 1000r / min, and collect tungsten powder in five batches;

[0041] 4) Hot pressing sintering: select three kinds of tungsten powders processed at 3500r / min, 280...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com